Dry Roasting Equipment---Tunnel Dryer---The Secondary Dryer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg/m²

- Supply Capability:

- 50 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

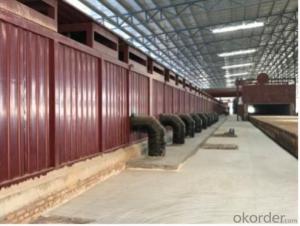

The carrier equipment of the green brick in the secondary dryer is a drying car. The bricks are stacked on the drying car by the racking system. After drying, the drying car is unloaded by the lowering system, and then the bricks are stacked on the kiln car by the racking system. This operation adopts a single layer drying method, which is suitable for raw materials with high moisture content, because each green brick is fully dried, and the drying efficiency is high.

The drying medium is generally provided by the waste heat of the roasting kiln and is supplemented by the burner when the heat is insufficient. The drying room is equipped with a hot air supply system, a moisture exhaust system and a temperature and humidity monitoring system. By monitoring and adjusting the system, the supply air temperature and air volume can be controlled to ensure the drying quality of the bricks.

The structure of the secondary dryer is a multi-channel brick-concrete structure or a multi-channel frame structure without partition walls to adapt to different drying requirements.

- Q: What is the best drying equipment?

- After the wet air is withdrawn from the inclined duct beneath the baking tray, a portion of the wet air is discharged from the oven through the centrifugal fan.

- Q: The working principle of belt dryer

- For dehydrated vegetables, the general use of three devices in series, the formation of early dry section, the middle section and the final section. In the early dry section, due to high water content of materials. Poor ventilation, so the use of a smaller thickness of the shop material, faster running speed and higher drying temperature. In the early dry section, the dry gas temperature can be as high as 120oC or more. The length of the material in the final section is 3-6 times of the initial dry section, and the thickness of the material is 2-4 times of the initial dry section.

- Q: What are the common types of dryers?

- The amount of operating parameters, can be independently controlled, so as to ensure the reliability of the work with dry and operating conditions optimization.

- Q: What are the common drying methods?

- Mechanical dehydration method is through the way of the material pressure, will be part of the water extrusion. Commonly used in pressing, sedimentation, filtration, centrifugal separation and other methods. Mechanical dehydration method can only remove part of the material free water, combined with water remains Material, so the material after the mechanical dehydration of the material moisture content is still high, generally 40 to 60%, but the mechanical dehydration method is one of the most economical method.

- Q: How to solve the dryer a series of failures

- The dew point reading can help to find some problems, so the dry air dew point value should be monitored throughout the drying process. Dryer normal operation of the dew point reading should be 20of ~ 50of within a straight line, of course, the replacement of the dryer caused by small fluctuations are normal. If the dryer is operating normally, the dew point at the dry air inlet should be at least 30of lower than the dew point at the return air outlet.

- Q: How to choose the right drying equipment and drying technology

- Hygroscopic materials can absorb moisture from the surrounding environment, non-hygroscopic materials can not absorb moisture from the environment.

- Q: What are the types of drying equipment?

- he equipment used for the drying operation. Many types. According to the operating pressure can be divided into atmospheric pressure and pressure (vacuum dryer also known as vacuum dryer). According to the operation method can be divided into intermittent and continuous. According to the drying medium can be divided into air, flue gas or other drying medium. According to the movement (material movement and drying medium flow) can be divided into parallel, countercurrent and cross flow.

- Q: The development prospects of the dryer

- As a compressed air post-processing purification equipment, cold and dry control system will follow the host control technology and continuous improvement. Frequency control, online dew point measurement and control, operating conditions, real-time display and record preservation and so there is a lot of things to do.

- Q: What are the characteristics of the drum dryer?

- The current resistance is small, you can use it to dry the granular material.Currently the development of domestic drum dryer has been in the world advanced level, from the practical sense, the drying device in addition to improving the shape of the internal device design, gas transport regulation and other details Factors, in other areas no longer have the technical leap and innovation, the current technology has been able to meet the general needs.

- Q: What is a combination of drying equipment?

- Recently, a combination of different drying methods and different drying principles has been widely used, and a drying device capable of exerting their own advantages and making up their respective shortcomings.

Send your message to us

Dry Roasting Equipment---Tunnel Dryer---The Secondary Dryer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg/m²

- Supply Capability:

- 50 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.