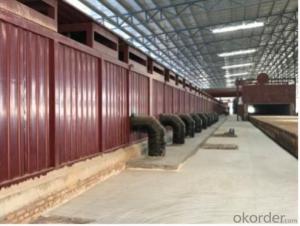

Dry Roasting Equipment---Draught Fan (It can be customized according to specific projects)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product introduction: including hot air blower (smoke heat), moisture exhaust fan (smoke heat), tunnel kiln smoke exhaust fan, kiln tail cooling fan, under-vehicle cooling fan, air supply fan (waste heat), and moisture exhaust fan (waste heat).

Note: It can be customized according to specific projects.

The fan is a machine that relies on the input mechanical energy to increase the gas pressure and discharge the gas. It is a driven fluid machine. Fan is the habitual abbreviation for gas compression and gas conveying machinery in China. Fans include ventilators, blowers, and wind generators.

Fans are widely used in ventilation, dust removal and cooling in factories, mines, tunnels, cooling towers, vehicles, ships and buildings, ventilation and induced draft in boilers and industrial furnaces; cooling and ventilation in air conditioning equipment and household appliances; Drying and selection of grain, air source of wind tunnel and inflation and propulsion of hovercraft, etc.

- Q: What is the best drying equipment?

- The machine will be part of the fan by the air, through the early, middle and high efficiency filter. To 100,000 purification, the steam heat exchanger, so that the air temperature to a certain temperature

- Q: The working principle of belt dryer

- For dehydrated vegetables, the general use of three devices in series, the formation of early dry section, the middle section and the final section. In the early dry section, due to high water content of materials. Poor ventilation, so the use of a smaller thickness of the shop material, faster running speed and higher drying temperature. In the early dry section, the dry gas temperature can be as high as 120oC or more. The length of the material in the final section is 3-6 times of the initial dry section, and the thickness of the material is 2-4 times of the initial dry section.

- Q: What are the basic types of common drying equipment?

- Common types of common drying equipment (1) slime dryer slime dryer its working principle is as follows: moisture content of 25 to 40% of the wet slime first after a special material scrambling device after the break up by the belt The machine is transported to the feeder, and then the wet slime is fed into the drying drum by the feeder. The slime is spread under the drying drum, and the slag is evenly dispersed and fully communicated with the hot air to reach the heat transfer, Mass transfer of purpose.

- Q: What are the common types of dryers?

- Roller scraper dryer is through the rotation of the cylinder, in a heat conduction way, will be attached to the outer wall of the cylinder liquid material or ribbon material, dry a continuous operation of equipment to be dry treatment of liquid from the high

- Q: What are the common drying methods?

- Drying method Drying is the process of removing moisture from various materials. Various materials can be solid, liquid or gas, solid and can be divided into large pieces of material, fiber material, pellets, fine powder and so on, Is the moisture in the material, it can be other solvents. In this water for the object. Drying equipment, there are three ways to dry: (1) mechanical dehydration

- Q: How to choose the right drying equipment and drying technology

- For non-hygroscopic materials, the moisture present in any environment remains on the surface and becomes "surface moisture" and is easily removed.

- Q: What are the types of drying equipment?

- According to the heating method, the dryer is divided into convection, conduction, radiation, dielectric and other types. Convection dryer, also known as direct dryer, is the use of hot dry media and wet material in direct contact with convection way to transfer heat, and the generated steam away; Conductive dryer also known as indirect dryer, which uses conduction The heat is transferred from the heat source through the metal wall to the wet material, and the resulting wet steam can be removed by means of reduced pressure suction, passing a small amount of purge gas or condensing it on a separately provided low

- Q: The development prospects of the dryer

- As an air compressor post-processing equipment, cold and dry machine is only a single auxiliary machine. But with the technological progress, the industrial sector on the gas quality requirements are getting higher and higher, cold and dry machine market will be more and more, it can be said, as long as the air compressor in the development of cold and dry machine prospects will be more and more it is good.

- Q: Frozen sublimation drying equipment which consists of several systems

- the heating system: for heating the freeze-drying room shelf, to promote the material within the ice sublimation, direct and indirect heating in two ways, direct heating is the direct heating in the box inside the shelf, indirect heating is the use of electricity Or other heat source heat transfer medium, and then pass it into the shelf.

- Q: What are the characteristics of the drum dryer?

- The main body of the rotary drum dryer is a slightly tilted and rotatable drum, and the wet material is fed from one end thereof and passes through the inside of the drum and is dried in contact with the hot air or the heated wall in the cylinder. , Chemical industry, metallurgy, building materials and other industries have a wide range of applications. Rotary drum drying and other drying equipment compared to the production capacity, continuous operation and simple structure, easy operation and less trouble, low maintenance costs

Send your message to us

Dry Roasting Equipment---Draught Fan (It can be customized according to specific projects)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.