Iron Manhole Cover from Casting Foundry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 110 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

1.Place of Origin: Hebei, China (Mainland)

2.Brand Name: CMAX

3.Model Number: EN124 Standard

4.Application: Construction

5.Material: Iron

6.Dimensions: OEM

7.Surface treatment: Painting

8.Process: Casting. Drilling. Threading

9.Certification: ISO9001:2008

10.Standard: EN124 Standard

11.Name: Iron Casting Parts

12.Color: Grey

13.Type: Moulding Press

14.Service: OEM Service

15.Size: Customer's Request

Advantage of ductile iron

Higher quality /higher tensile

Higher security /long life

Packaging and Shipping

Delivery Detail: 8 days if your order is 20"container

Packaging: Details Pallet with bubble film, Carton or with pallet

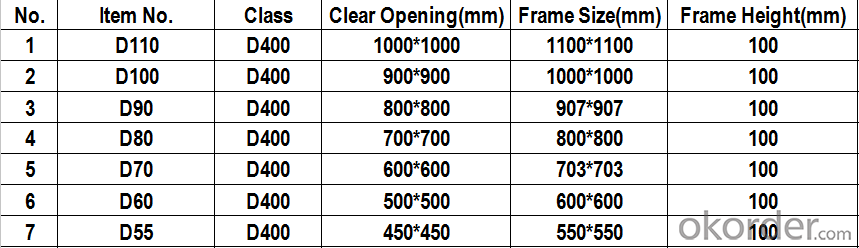

Specification

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers.

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Professional technical support with free charge.

5. After the cooperation: Any of your problem will be solved within 24 hours.

- Q: How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- The material is usually steel material price plus the cost (per ton of 2.5-3 million, plus profit).In the Yangtze River Delta region, generally 304 casting price of about 5-5.5 million / ton.The price will be higher if the parts are complex, or a piece weighs less than 100 grams.

- Q: How to improve the surface roughness of casting parts?

- One is to improve the accuracy of the model; the two is to improve the molding sand mesh. How much is the other relationship?.

- Q: Why does the surface of stainless steel casting mirror mirror ripple?

- Those should be head prints. If required, it would be better to throw with a single grinding head.

- Q: The casting defects of pores, trachoma how to repair?

- If the repair after the high temperature resistance, choose LT737 high temperature repair agent.

- Q: What are the effects of stiffeners on castings, or on welded parts (for 2 tons or less), casting or weldments on stiffeners?

- 3, weight: if reinforcement in products, casting weight is generally greater than the welding parts (the internal organizational structure and mode of production determines the mechanical properties of materials, so it determines the weight of the product), considering the cost of transportation, certain priority structure.

- Q: Why do cheap cars like stamping parts instead of casting parts?

- Separation process is also called blanking, the purpose is to make the stamping parts along a certain contour line from the sheet metal separation, at the same time guarantee the quality requirements of the separation section. Stamping is a highly efficient production methods, the use of compound die, especially the multi station progressive die stamping process can be completed in a multi machine, realized by belt uncoiling, leveling, punching, forming and finishing automatic production. High production efficiency, good working conditions, low production costs, can produce hundreds of parts per minute. The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning, and straightening are the main types of stamping machines.

- Q: How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q: The casting sand is going on

- Dispersed sand inclusion is common on the surface and subcutaneous of steel castings, often concentrated on the outer surface of the upper box and the inner surface of the lower case, and a few of them are inside the cast steel parts.

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: Where is the precision casting factory?

- Shandong, DongyingThe birthplace of precision casting

Send your message to us

Iron Manhole Cover from Casting Foundry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 110 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords