Integral Blade Stabilizer Using in Oilfield

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Integral Blade Stabilizer Description

Integral Blade Stabilizer is a one piece rotating stabilizer which can be placed near bit or up in the drill string. It is a one piece construction manufactured from high strength alloy steel (non-magnet steel optional).

It prevents differential sticking of the drill string by stabilizing the BHA and keeping drill collars and drill pipes away from the borehole wall. This reduces vibration, drill pipe whirl, and well bore tortuosity; furthermore, the stabilization maintains drilling trajectory whether drilling straight, horizontal, or directional wells.

2. Main Features of Integral Blade Stabilizer

1) Advanced test for quality

2) MTC provided

3) Good price and service

3. Integral Blade Stabilizer Images

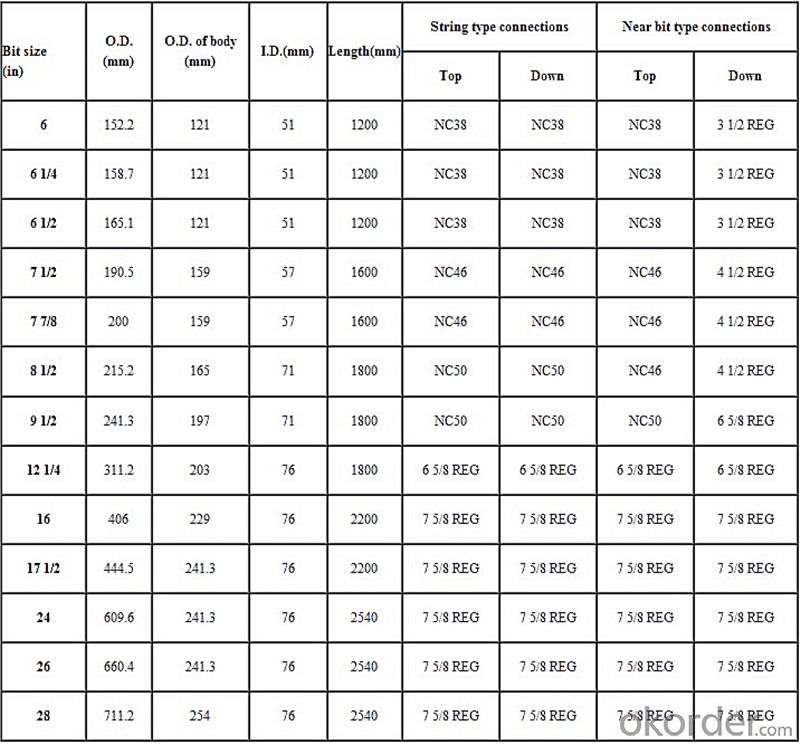

4. Integral Blade Stabilizer Specification

5. FAQ of Integral Blade Stabilizer

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers in China, mainly offering various of oilfield products consists of our one-stop sales. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: Why does the centrifugal pump close the pressure to start?

- The flow is zero (i.e. off dead) minimum, the highest lift power; with the outlet valve opening increases, flow increases, the lift, power and efficiency are increased, the maximum value (usually in the vicinity of the highest rated flow point)

- Q: What is the dry running protector of screw pump? What's the principle and function? Thank you

- When the temperature reaches a certain value, the signal is transmitted to the electric control box through a dry running protector, and the electric control box is used to stop the screw pump so as to protect the screw pump.

- Q: The main factors affecting the performance of centrifugal pumps

- Revolutions required to have. It has the following meanings: 1, similar to the geometry of centrifugal pump, everywhere efficiency at the top of the similar condition; centrifugal pump 2, than the number of different, its geometry must be different than the number; the same pump, its shape is similar, but does not rule out the shape similar situation. The following factors are related to specific speed. The specific speed of centrifugal pump has nothing to do with the nature of the conveying fluid, but has a close relationship with the shape of the impeller and the performance curve of the pump. The pump with high specific speed corresponds to the highest efficiency when the flow rate is large and the head is small

- Q: Please give me professionals to calculate, the cylinder bore is 100 and the rate of 20m/s, the leakage can be ignored, but to the large flow pump!

- 1. rpmOperating speed is the actual rotation speed of a pump (or motor) at work.Rated speed is the maximum speed that can operate normally for a long time under rated pressure. If the pump exceeds the rated speed, the work will cause insufficient oil absorption, vibration and noise, the parts will suffer cavitation damage, life expectancy.Minimum steady speed is the minimum speed allowed for normal motor operation. At this speed, the motor does not appear crawling phenomenon.

- Q: What is the function of the heating pump system for the water pump design?

- As the feed water temperature is higher, before starting, if not enough to warm the pump, the pump body temperature is uneven, there is a hot, cool phenomenon. The upper part is inflated and the lower part is inflated"

- Q: What is the liquid pump? What are their categories? What are their strengths and weaknesses?

- The air driven liquid pump adopts compressed air driving method, and has the following advantages:The pressure can be adjusted by manual pressure control valve or air control valveIt is driven by air and is especially suitable for explosion protection applicationsAble to achieve pre-set final pressureAutomatic pressure relief by pumpLong term conservation without consuming energyWhen holding pressure, medium will not overheatThe utility model has the advantages of convenient installation and low maintenance cost, and only needs to connect the gas source, the inlet pipeline and the pressure pipelineReliable operation, low maintenance cost and little noise at the time of operation

- Q: How can I buy a pump?

- Selection principle of pump:1, so that the selected pump type and performance parameters meet the unit flow, lift, pressure, temperature and other requirements, the most important thing is to determine the voltage, the maximum lift, and when the head high reached much traffic.

- Q: If the calculation of the required pump flow is 45, lift 110, and the actual pump flow 100, head 125, what will happen in operation? Can I use it properly?

- First of all, the performance curve of the centrifugal pump is similar to the track of the train, and the train can not run away from the track.Secondly, the performance curves of centrifugal pump mainly include flow head curve, efficiency flow curve, power flow curve. When the pump is ready, the curve is fixed. In practical application, after determining the flow rate, the corresponding lift head, efficiency and power (relative to density) are determined. General requirements for centrifugal pump operating in the vicinity at the highest point of efficiency, the efficiency of the flow curve is similar to parabola, so if the actual operation condition deviated from the rated point, whether large or small, will cause the decline in pump efficiency (generally rated value is less than 15%), increased operating costs.

- Q: Why does the centrifugal pump start with a closed valve and the axial pump starts with an opening valve?

- The power of axial flow pump decreases with the increase of flow rate, and it is a steep curve, so the centrifugal pump starts with an open valve.

- Q: What does "dual purpose" of water pump mean? Please expert advice

- 2, the pump must pay attention to maintenance after use, for example, when the pump is used up, the water pump should be put clean, it is best to remove the water pipe, and then rinse with water.5, the water pump on the tape should be removed, and then rinse with water after drying in the light place, do not put the tape in the dark damp place. Water pump tape must not be stained with oil, not to tape coated with some sticky things.6, to carefully check whether there are cracks in the impeller, the impeller fixed to the bearing on whether there is loose, cracks and loose if the phenomenon to be timely maintenance, if the water pump impeller should also be above the earth clean.

Send your message to us

Integral Blade Stabilizer Using in Oilfield

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords