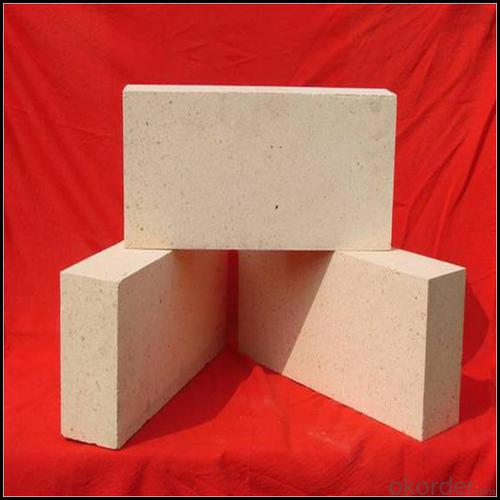

Insulating Fire Brick SK34 High Alumina Refractory Brick for Furnace Liner

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.01

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Brick

CMAX firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay by mixing, press-forming, drying, sintering and machining. Bricks contain carefully-graded organic fillers which are burned out during sintering to give a uniform controllable pore structure. This technique makes product feature low thermal conductivity and excellent heat insulation

Features

1.low creep deformation

2.huge heat capacity

3.great refractoriness

4.thermal shock resistance

Application

1.Carbon bake furnaces in the aluminum industry

2.Preheat zones and cyclones of rotary cement kilns

3.insulation for glass tanks

4.Coke ovens

5.Blast furnaces

6.Reheating furnaces

7.Suspended roofs

8.Lime kilns

9.Chimney

10.BBQ/Pizza Ovens

Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Sales Network

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: Do insulating fire bricks require any special curing or firing temperature profiles?

- Special curing and firing temperature profiles are indeed necessary for insulating fire bricks. These bricks are made from lightweight materials like perlite, vermiculite, or alumina silicate, all of which possess exceptional insulating properties. Their design enables them to endure high temperatures while providing superior thermal insulation. Throughout the manufacturing process, insulating fire bricks undergo a curing procedure to eliminate any moisture content. This is typically achieved by gradually raising the temperature in a controlled manner. The curing process is essential to prevent any potential cracking or damage that may occur if the bricks were subjected to high temperatures too quickly. When it comes to firing temperature profiles, careful consideration is required for insulating fire bricks. They are specifically designed for applications where temperatures can reach up to 2800°F (1538°C). Therefore, it is crucial to adhere to the recommended firing temperature profiles provided by the manufacturer. The firing temperature profile usually involves a gradual increase in temperature to allow the insulating fire bricks to reach the desired maximum temperature without experiencing any thermal shock or damage. This gradual heating process ensures that the bricks are adequately cured and capable of withstanding the extreme temperatures they will encounter during use. It is worth noting that the specific curing and firing temperature profiles may vary depending on the type and composition of the insulating fire bricks. Consequently, it is vital to consult the manufacturer's guidelines and recommendations to ensure the proper curing and firing process for the specific type of insulating fire bricks being utilized.

- Q: Are insulating fire bricks resistant to water penetration?

- Yes, insulating fire bricks are resistant to water penetration. These bricks are designed to have a low porosity and are made from materials that are not prone to absorbing or retaining water. They are typically composed of lightweight refractory materials such as alumina, silica, and other minerals that have high heat resistance and low water absorption properties. This makes insulating fire bricks ideal for applications where water penetration could be detrimental, such as in high-temperature environments or when used as insulation in chimneys or kilns. However, it is important to note that while these bricks are resistant to water penetration, they are not completely impervious to it. Prolonged exposure to water may eventually lead to some level of water absorption, which can affect their insulating properties. Therefore, it is advisable to take precautions and ensure proper installation and maintenance to maximize their resistance to water penetration.

- Q: Do insulating fire bricks have low thermal conductivity?

- Yes, insulating fire bricks have low thermal conductivity.

- Q: What is the price of thermal insulation brick for exterior wall?

- Hello, the exterior wall insulation has many practices, useful insulation bricks, but also useful particles of polystyrene insulation mortar mixed (thickness is not the same, the price is not the same);

- Q: What industries commonly use insulating fire bricks?

- Insulating fire bricks are commonly used in industries such as steel, aluminum, ceramics, glass, and cement production, as well as in various high-temperature applications like furnaces, kilns, incinerators, and thermal insulation systems.

- Q: Can insulating fire bricks be used in the construction of combustion chambers?

- The use of insulating fire bricks in combustion chambers is highly recommended. These bricks are created using lightweight, porous materials that possess exceptional thermal insulation capabilities. As a result, they are extremely suitable for high-temperature applications like combustion chambers, where their insulation aids in the containment and regulation of heat generated during the combustion process. The heat transfer resistance of insulating fire bricks is notably high, enabling them to effectively retain heat within the combustion chamber. This, in turn, enhances combustion process efficiency by minimizing heat loss to the surrounding environment. Moreover, these bricks' insulating properties help prevent the outer walls of the combustion chamber from overheating, thereby reducing the risk of structural damage. Furthermore, insulating fire bricks are specifically designed to endure elevated temperatures, rendering them highly durable and resilient. This is particularly crucial in combustion chambers, where intense heat and varying temperatures are commonplace. Their ability to withstand thermal shock and thermal cycling makes them a dependable choice for this purpose. To summarize, insulating fire bricks are an exceptional option for constructing combustion chambers due to their thermal insulation properties, heat retention ability, and resistance to high temperatures. They significantly contribute to the overall efficiency and safety of the combustion process, making them an invaluable component in combustion chamber construction.

- Q: Do insulating fire bricks have any impact on indoor air quality?

- Insulating fire bricks, also known as refractory bricks, are primarily used in high-temperature applications such as fireplaces, kilns, and furnaces. These bricks are designed to withstand extreme heat and provide insulation, preventing the transfer of heat to surrounding areas. In terms of indoor air quality, insulating fire bricks do not have a direct impact. Since insulating fire bricks are made from materials such as clay, alumina, and silica, they are generally inert and do not release any harmful substances into the air when exposed to normal temperatures. However, it is important to note that during the manufacturing process, certain chemicals or additives may be used, which could potentially have an impact on air quality if not properly regulated or controlled. Additionally, the installation and maintenance of insulating fire bricks can indirectly affect indoor air quality. For example, if the bricks are not installed correctly or become damaged over time, they may develop cracks or gaps that could allow the escape of harmful gases or particulate matter. In such cases, it is crucial to promptly repair or replace damaged bricks to ensure the integrity of the insulation and prevent any negative impact on indoor air quality. Furthermore, the use of insulating fire bricks in fireplaces or wood-burning stoves can indirectly influence indoor air quality. When these devices are operated, they can release smoke, particulate matter, and potentially harmful gases into the air. It is essential to ensure proper ventilation and use high-quality flue systems to minimize the impact on indoor air quality when using such appliances. In summary, insulating fire bricks themselves do not have a direct impact on indoor air quality. However, it is important to consider factors such as the manufacturing process, installation, and maintenance to ensure that these bricks do not contribute to any degradation of the air we breathe.

- Q: Can insulating fire bricks be used in ceramic fiber blankets?

- No, insulating fire bricks cannot be used in ceramic fiber blankets. Insulating fire bricks are solid and rigid, while ceramic fiber blankets are flexible and designed for insulation purposes. They serve different functions and have different properties, making them incompatible for use together.

- Q: What is the bulk density of the sintered bricks?

- Sludge brick density is about 1000Kg/m or so fand.

- Q: Can insulating fire bricks be used in electric arc furnaces?

- Insulating fire bricks are capable of being used in electric arc furnaces. Constructed from lightweight materials possessing excellent insulation capabilities, these bricks are well-suited for scenarios necessitating heat insulation. Due to the high temperatures generated by electric arc furnaces, effective insulation is imperative to confine the heat within the furnace chamber. The insulating fire bricks are able to endure the extreme heat emitted by these furnaces, thus averting heat loss and conserving energy. Furthermore, their insulating properties contribute to maintaining a steady temperature inside the furnace, ensuring the efficient melting and refining of metals or other materials. Consequently, insulating fire bricks present a suitable option for implementation in electric arc furnaces.

Send your message to us

Insulating Fire Brick SK34 High Alumina Refractory Brick for Furnace Liner

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.01

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords