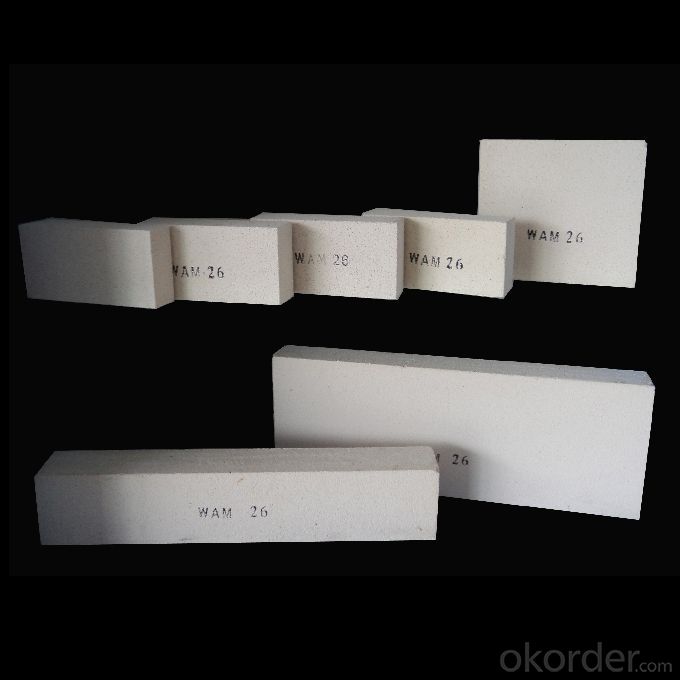

Insulating Fire Brick - Refractory Mulite Insulating Fire Brick GJM25

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

- Q: Refractory bricks, burner bricks, insulation bricks? Is it a kind of thing?

- The burner brick is heavy brick, the use temperature is higher, the insulating brick is light brick, the use temperature is lower than the heavy brick.

- Q: How do insulating fire bricks affect energy efficiency?

- The use of insulating fire bricks is essential for improving energy efficiency in various applications. These bricks are specifically designed to have low thermal conductivity, allowing them to minimize heat transfer effectively. By reducing the amount of heat that escapes or enters a system, insulating fire bricks help conserve energy and maintain optimal temperature levels. In industrial furnaces and kilns, insulating fire bricks serve as a barrier, preventing heat dissipation into the surrounding environment. This results in reduced energy consumption as the heat is retained within the system, enabling more efficient and cost-effective operation. Additionally, insulating fire bricks can decrease the time required for the system to reach and maintain the desired temperature, further enhancing energy efficiency. For residential and commercial buildings, insulating fire bricks are utilized in the construction of fireplaces, stoves, and chimneys. These bricks effectively trap heat within the combustion chamber, preventing it from escaping through the walls. Consequently, the heat generated by the fire is utilized more efficiently, reducing the need for additional heating sources and ultimately saving energy. Furthermore, insulating fire bricks are also used to insulate pipelines, boilers, and other equipment requiring thermal protection. By minimizing heat transfer through these components, energy losses are reduced, resulting in improved energy efficiency. In conclusion, insulating fire bricks play a significant role in enhancing energy efficiency by minimizing heat loss, maximizing heat retention, and optimizing temperature control in various applications. Their low thermal conductivity properties make them an essential component in systems where energy conservation and cost-effectiveness are critical factors to consider.

- Q: Do insulating fire bricks require preheating before use?

- Yes, insulating fire bricks typically require preheating before use. Preheating the bricks helps to remove any moisture or volatile organic compounds that may be present in the material. This is important because moisture or volatile compounds can cause the bricks to crack or even explode when exposed to high temperatures. Preheating also helps to condition the bricks and prevent thermal shock, which can occur when the bricks are rapidly exposed to extreme temperatures. By slowly and gradually increasing the temperature, the bricks are able to expand and contract without any damage. Therefore, it is recommended to preheat insulating fire bricks before using them in order to ensure their durability and performance.

- Q: What is the typical density of an insulating fire brick?

- The typical density of an insulating fire brick can vary depending on the specific composition and manufacturing process. However, in general, insulating fire bricks have a lower density compared to regular fire bricks. The typical density of an insulating fire brick can range from 0.8 g/cm³ to 1.2 g/cm³. This lower density is achieved by incorporating insulating materials like lightweight aggregates or organic fibers into the brick's composition, which helps to reduce heat transfer and increase thermal insulation properties.

- Q: Can insulating fire bricks be used in crucibles?

- No, insulating fire bricks cannot be used in crucibles. Insulating fire bricks are designed to have low thermal conductivity and are commonly used for insulation purposes in applications such as kilns, furnaces, and fireplaces. However, crucibles require materials with high thermal conductivity and resistance to high temperatures to withstand the intense heat and chemical reactions that occur during various processes such as melting or refining metals, conducting high-temperature experiments, or performing chemical reactions. Therefore, crucibles are typically made from materials such as graphite, clay, or ceramic, which can withstand the extreme conditions and provide efficient heat transfer.

- Q: Is it possible to repair damaged insulating fire bricks?

- Yes, it is possible to repair damaged insulating fire bricks. The damaged bricks can be repaired by using refractory cement or mortar to fill in cracks or gaps. Additionally, damaged portions can be cut out and replaced with new bricks. However, the extent of the damage and the specific repair method required may vary depending on the severity of the damage.

- Q: How do insulating fire bricks help improve the efficiency of heating systems?

- Insulating fire bricks play a crucial role in improving the efficiency of heating systems by providing excellent thermal insulation. These bricks are specifically designed to have low thermal conductivity, which means they are able to minimize the transfer of heat from the heating system to the surroundings. By using insulating fire bricks, the heat generated by the heating system is effectively contained within the system itself, allowing for more efficient heating. This is particularly important in applications where energy conservation is a priority, as it helps to reduce heat loss and minimize energy wastage. Moreover, insulating fire bricks have high heat retention capabilities, which means they can store and radiate heat for extended periods of time. This characteristic enables the heating system to maintain a more consistent and stable temperature, resulting in improved comfort and reduced energy consumption. Additionally, insulating fire bricks also offer excellent resistance to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. This durability ensures the longevity of the heating system and minimizes the need for frequent repairs or replacements, further enhancing its overall efficiency. In summary, insulating fire bricks contribute to the improvement of heating system efficiency by reducing heat loss, enhancing heat retention, and providing durability against thermal shock. By utilizing these bricks, heating systems can operate more effectively, consume less energy, and provide superior comfort.

- Q: Can insulating fire bricks be used for insulation in steam pipes?

- Yes, insulating fire bricks are a suitable option for insulation in steam pipes. These bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. They have low thermal conductivity, which means they prevent the transfer of heat effectively. This property makes them ideal for insulating steam pipes, as it helps to minimize heat loss and maintain the temperature of the steam inside the pipes. Additionally, insulating fire bricks are lightweight and easy to install, making them a convenient choice for insulating steam pipes.

- Q: What bricks are thermal insulation bricks?

- First, replace the aluminum plate, honeycomb board, curtain wall and other common decorative materials, multi-functional integration, a construction can solve the two requirements of thermal insulation decoration, smooth, smooth and beautiful, decorative strong.Two, high strength, good rigidity, light quality, seismic resistance, wind resistance, creep resistance, superior performance, reduce building load, more economical and durable.Three, fire retardant, heat preservation, energy saving, sound insulation, heat insulation, crack resistance, waterproof, according to the 65% building energy conservation requirements for construction design.Four. The installation of the finished product is simple, the process is simplified, the construction period is shortened, and the quality is easy to control.Five, no aluminum, steel, keel support, embedded in the installation, reduce the insulation board and the gap between the wall. Increased safety system.Six, no radiation, green environmental protection, can be widely used in various types of public buildings and family interior decoration.

- Q: Are insulating fire bricks resistant to molten salts?

- Yes, insulating fire bricks are generally resistant to molten salts due to their high melting point and low porosity, which prevents the salts from penetrating the material.

Send your message to us

Insulating Fire Brick - Refractory Mulite Insulating Fire Brick GJM25

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords