Insulating Fire Brick - Refractory JM Mullite Insulation Brick ZDC-26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

light insulation brick

1. refractories

2. silica insulation brick

3. light insulation brick

4. glass furnace

Refractory mullite insulating refractory brick JM 23

Okorder series heat insulation brick

Okorder series thermal insulation brick is an effective, energy saving, low carbon, environmental protection advanced, according to the ASTM standard manufacturing products. Okorder series products are best Li Ning and insulation in all types of industrial furnaces in the metallurgical field, aluminum, petrochemical, electric power and glass ceramic materials. They can be used as part of the working layer of thermal insulation or non - melting. Products have been widely used in the following furnace, achieved satisfactory results.

Application of heat preservation brick

Metallurgical Industry: blast furnace, hot blast furnace, heating furnace, etc..

Petrochemical Industry: ethylene cracking furnace, hydrogen production furnace, primary reformer, heating furnace, etc..

Ceramic industry: roller kiln, kiln, etc..

Glass industry: glass furnace regenerator, etc.

Carbon industry: carbon furnace, etc..

Aluminum electrolysis industry: aluminum reduction cell, etc.

Other industries: tunnel kiln, shuttle kiln, etc..

Advantages of heat insulation brick

Low thermal conductivity: more porosity will bring good thermal insulation effect, energy saving.

High crushing strength: high crushing strength, volume stability.

Low heat storage: small heat storage to absorb more heat, energy-saving effect is obvious.

Gao Chundu: iron, alkali metal impurity content is low.

The precise size: Brick size processing precision, special shape cutting and grinding, accelerate the brickwork.

Insulating brick picture

Common problem solutions

1. What products do you have?

We have all kinds of refractory bricks, refractory casting materials, mortar, cement, ceramic fiber products, etc..

Or you can browse our products to choose what you need.

2. How to control product quality?

With strict quality control system throughout the material selection and production process, we have the quality of refractory materials and ceramic fiber products to meet customer requirements.

From the selection of raw materials, the quality of our control to start. The quality certificate of the raw material is required, each batch of the products are to be tested in the use of the forward line. In the production process, the quality control by the workers, and then each piece of classification, and through the quality supervision and inspection.

3. Can you give me a brief introduction to the application of your product?

My company is mainly engaged in refractories in the steel, cement, glass, ceramics, petrochemical, electric power and other industries.

4. What information do you need if I need you?

In order to select the right products, we will provide us with information, such as the United States, technical data, order quantity, product application, etc..

If you have any questions, please contact us.

Product Description

Light insulation brick

Description

The insulating firebricks are made from high purify raw materials and follows the ASTM C155 classification. These IFB’s contain a carefully graded organic filler which is burned out during firing to give a uniform controlled pore structure and after are machined to precise tolerances on all surfaces.

Features

- Use limit up to 1760°C

- Excellent strength and thermal stability

- Low thermal conductivity

- Low Heat Storage

- High Purity

- Very big range of available sizes and formats

- Very accurate dimensions

Applications

Recommended as hot face and backup insulation in all industries and applications.

Special Shapes

In addition to the standard brick sizes, our bricks are available in pre-machined special shapes as well as Suspended Roof Blocks!

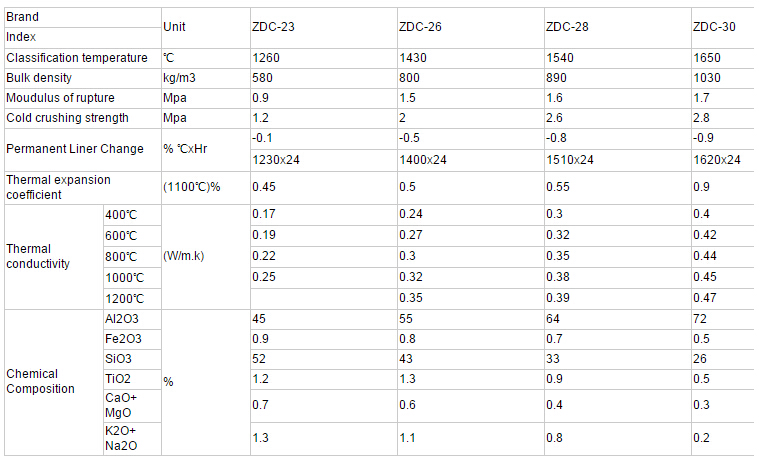

Technical Specification:

- Q: Are insulating fire bricks resistant to slag attack?

- Insulating fire bricks have a general resistance to slag attack. They are made from lightweight and porous materials, like alumina, silica, and other refractory materials. These bricks are designed to provide excellent insulation and high-temperature resistance in various industrial applications, such as furnaces, kilns, and incinerators. When we talk about slag attack, we are referring to the corrosion or erosion caused by molten slag. This slag is a byproduct of certain industrial processes, such as metal smelting or coal combustion. It can be highly corrosive and damage refractory materials, including fire bricks. However, insulating fire bricks are specifically formulated to resist slag attack. They have a composition and structure that allows them to withstand the corrosive nature of molten slag. This helps prevent erosion and maintain their insulating properties over time. Furthermore, insulating fire bricks can have different levels of slag resistance, depending on their specific composition and manufacturing process. Some fire bricks may even have additives or coatings to enhance their resistance to slag attack. It's important to note that while insulating fire bricks offer good resistance to slag attack, the severity and duration of exposure to slag can impact their performance. In highly corrosive environments or prolonged exposure to molten slag, even the most resistant fire bricks may eventually experience some degradation. Overall, insulating fire bricks are a reliable choice for applications where resistance to slag attack is necessary. However, it's always recommended to consult with a refractory engineer or supplier to ensure the appropriate selection of fire bricks based on the specific conditions and requirements of the industrial process.

- Q: Can insulating fire bricks be used for sound insulation?

- No, insulating fire bricks are primarily designed for high-temperature applications such as lining furnaces, kilns, or fireplaces, and are not effective for sound insulation purposes.

- Q: Can insulating fire bricks be used in the construction of heat recovery systems?

- Yes, insulating fire bricks can be used in the construction of heat recovery systems. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them an ideal choice for heat recovery systems. These bricks are made from lightweight materials, such as ceramic fibers or refractory materials, which have low thermal conductivity. This property allows them to effectively trap and retain heat, preventing it from escaping the system and maximizing energy efficiency. Additionally, insulating fire bricks are resistant to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. This makes them suitable for the varying heat conditions often found in heat recovery systems. Overall, using insulating fire bricks in the construction of heat recovery systems can help improve their performance and efficiency by minimizing heat loss and optimizing energy recovery.

- Q: Can insulating fire bricks be used in the construction of pottery extruders?

- Yes, insulating fire bricks can be used in the construction of pottery extruders. These bricks are known for their high heat resistance, low thermal conductivity, and excellent insulating properties, making them suitable for applications where high temperatures are involved, such as pottery extrusion. They can help maintain a consistent temperature within the extruder, ensuring optimal working conditions for the clay and improving overall efficiency.

- Q: What is the typical lifespan of an insulating fire brick?

- The typical lifespan of an insulating fire brick can vary depending on various factors such as the quality of the brick, the temperature it is exposed to, and the frequency of thermal cycling. However, on average, insulating fire bricks can last anywhere from 5 to 20 years.

- Q: Are insulating fire bricks resistant to hydrogen sulfide?

- Yes, insulating fire bricks are generally resistant to hydrogen sulfide due to their high melting point and chemical stability.

- Q: Do insulating fire bricks require a protective coating for outdoor use?

- Insulating fire bricks have been specifically engineered to endure high temperatures and offer thermal insulation. While they are commonly applied indoors, such as in kilns, furnaces, and fireplaces, they can also be utilized outside. However, the necessity of a protective coating for outdoor use relies on the specific circumstances and environment in which they will be employed. Generally, insulating fire bricks are composed of materials like clay or alumina silicate, which possess inherent resistance to weathering and environmental factors. They can tolerate exposure to rain, snow, and even extreme temperatures without significant deterioration. These bricks are often classified as refractory materials due to their heat resistance, rendering them highly durable in outdoor settings. Nonetheless, there may be instances where it is advisable to apply a protective coating to the insulating fire bricks for additional protection. For example, if the bricks will be continually exposed to harsh weather conditions, prolonged UV radiation, or corrosive substances, a protective coating can enhance their longevity. The selection of coating will depend on the specific requirements and anticipated conditions. Various options are available, such as high-temperature paint, ceramic coatings, or silicone-based sealants. These coatings can furnish an additional layer of safeguarding against moisture, chemicals, and temperature fluctuations, ensuring the bricks retain their insulation properties and structural integrity over time. In conclusion, insulating fire bricks are generally suitable for outdoor use without necessitating a protective coating, as they are specifically designed to withstand high temperatures and adverse weather conditions. However, if the bricks will be exposed to particularly harsh or corrosive environments, applying an appropriate protective coating can offer additional durability and ensure their longevity. It is always recommended to seek guidance from experts or manufacturers for specific advice based on the intended use and outdoor conditions.

- Q: Can insulating fire bricks be used in the construction of industrial furnaces?

- Yes, insulating fire bricks can be used in the construction of industrial furnaces. These bricks are designed to withstand high temperatures and have excellent thermal insulation properties, making them ideal for lining the walls, roofs, and floors of industrial furnaces. They help to reduce heat loss, improve energy efficiency, and ensure the furnace operates at optimal temperatures.

- Q: Are insulating fire bricks suitable for commercial or industrial applications?

- Yes, insulating fire bricks are suitable for commercial and industrial applications. They are commonly used in high-temperature environments such as furnaces, kilns, and ovens, where they provide excellent insulation and heat resistance. Their ability to withstand extreme temperatures and thermal shock makes them ideal for commercial and industrial settings where heat containment and energy efficiency are crucial.

- Q: Do insulating fire bricks have a high compressive strength?

- Yes, insulating fire bricks typically have a high compressive strength due to their dense and sturdy composition.

Send your message to us

Insulating Fire Brick - Refractory JM Mullite Insulation Brick ZDC-26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords