Insulating Fire Brick - Refractory JM Mullite Insulation Brick B-7

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory mullite insulating refractory brick JM 23

Okorder series heat insulation brick

Okorder series thermal insulation brick is an effective, energy saving, low carbon, environmental protection advanced, according to the ASTM standard manufacturing products. Okorder series products are best Li Ning and insulation in all types of industrial furnaces in the metallurgical field, aluminum, petrochemical, electric power and glass ceramic materials. They can be used as part of the working layer of thermal insulation or non - melting. Products have been widely used in the following furnace, achieved satisfactory results.

Application of heat preservation brick

Metallurgical Industry: blast furnace, hot blast furnace, heating furnace, etc..

Petrochemical Industry: ethylene cracking furnace, hydrogen production furnace, primary reformer, heating furnace, etc..

Ceramic industry: roller kiln, kiln, etc..

Glass industry: glass furnace regenerator, etc.

Carbon industry: carbon furnace, etc..

Aluminum electrolysis industry: aluminum reduction cell, etc.

Other industries: tunnel kiln, shuttle kiln, etc..

Advantages of heat insulation brick

Low thermal conductivity: more porosity will bring good thermal insulation effect, energy saving.

High crushing strength: high crushing strength, volume stability.

Low heat storage: small heat storage to absorb more heat, energy-saving effect is obvious.

Gao Chundu: iron, alkali metal impurity content is low.

The precise size: Brick size processing precision, special shape cutting and grinding, accelerate the brickwork.

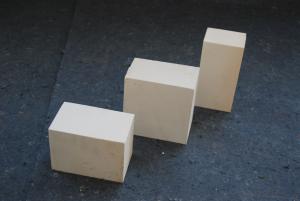

Insulating brick picture

Common problem solutions

1. What products do you have?

We have all kinds of refractory bricks, refractory casting materials, mortar, cement, ceramic fiber products, etc..

Or you can browse our products to choose what you need.

2. How to control product quality?

With strict quality control system throughout the material selection and production process, we have the quality of refractory materials and ceramic fiber products to meet customer requirements.

From the selection of raw materials, the quality of our control to start. The quality certificate of the raw material is required, each batch of the products are to be tested in the use of the forward line. In the production process, the quality control by the workers, and then each piece of classification, and through the quality supervision and inspection.

3. Can you give me a brief introduction to the application of your product?

My company is mainly engaged in refractories in the steel, cement, glass, ceramics, petrochemical, electric power and other industries.

4. What information do you need if I need you?

In order to select the right products, we will provide us with information, such as the United States, technical data, order quantity, product application, etc..

If you have any questions, please contact us.

- Q: What are the different types of insulating fire bricks available?

- There are various types of insulating fire bricks available, each possessing unique characteristics and applications. Some of the most common types are: 1. Lightweight Insulating Fire Bricks (IFBs): These bricks consist of lightweight materials, such as expanded clay, perlite, or vermiculite, blended with a binder to create a porous structure. They offer exceptional insulation properties and find wide usage in applications where maintaining high temperatures is crucial, like in kilns or furnaces. 2. Mullite Insulating Fire Bricks: Mullite bricks are composed of a combination of alumina and silica, resulting in a material resistant to high temperatures. These bricks exhibit excellent thermal shock resistance and are frequently utilized in applications involving rapid heating and cooling cycles, such as in glass manufacturing or incinerators. 3. Alumina Insulating Fire Bricks: As the name suggests, these bricks are primarily made from alumina, which is highly resistant to high temperatures. They possess excellent thermal conductivity and are commonly employed in industries where maintaining high temperatures is essential, such as the iron and steel industry or ceramics production. 4. Silica Insulating Fire Bricks: Silica bricks are mainly composed of silica, a heat-resistant material. They exhibit exceptional thermal insulation properties and are commonly used in applications where maintaining high temperatures is necessary, like in the construction of kilns or furnaces. 5. Calcium Silicate Insulating Fire Bricks: These bricks are created by combining calcium silicate with other insulating materials. They possess excellent thermal insulation properties and are often employed in industries where maintaining high temperatures is crucial, such as the petrochemical industry or power plants. Ultimately, the choice of insulating fire brick depends on the specific requirements of the application, including temperature resistance, thermal conductivity, and thermal shock resistance. It is vital to select the appropriate type of insulating fire brick to ensure optimal performance and safety.

- Q: Can insulating fire bricks be used as a base material for casting refractory shapes?

- Yes, insulating fire bricks can be used as a base material for casting refractory shapes. Insulating fire bricks have good thermal insulation properties and high temperature resistance, making them suitable for creating refractory shapes that can withstand extreme heat conditions.

- Q: What is mullite insulation brick?

- Main features of mullite insulating bricks:1., green environmental protection, non-toxic, non corrosive, safe to use.2. 、 good adaptability with cement.3., light insulation brick with foam mechanism bubble, can get foam uniform bubble diameter.4. excellent foaming performance, foaming multiples of more than thirty times.

- Q: Are insulating fire bricks resistant to nitric acid?

- Insulating fire bricks usually lack resistance against nitric acid, a highly corrosive substance that can dissolve various materials, including specific types of fire bricks. Although insulating fire bricks are intended for enduring high temperatures and providing thermal insulation, they may not possess the required chemical resilience to withstand the corroding impact of nitric acid. When anticipating exposure to nitric acid, it is recommended to employ materials specifically engineered for acid resistance in such situations.

- Q: Can insulating fire bricks be used in the construction of thermal oxidizers?

- Yes, insulating fire bricks can be used in the construction of thermal oxidizers. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for applications such as thermal oxidizers, which require efficient heat transfer and containment of high temperatures.

- Q: Are insulating fire bricks resistant to gas permeability?

- Yes, insulating fire bricks are resistant to gas permeability. They have low porosity and high density, which prevents the penetration of gases, making them an effective barrier against gas permeation.

- Q: Are insulating fire bricks resistant to water penetration?

- Yes, insulating fire bricks are generally resistant to water penetration. They are made using materials that have low porosity, which helps prevent water from seeping through. However, it is worth noting that prolonged exposure to water or high humidity conditions can still lead to some water absorption over time.

- Q: Can insulating fire bricks be used in cement kilns?

- Indeed, in cement kilns, insulating fire bricks find their utility. These bricks are specifically engineered with a low thermal conductivity, rendering them an excellent choice for insulating environments that endure high temperatures, like cement kilns. By employing these bricks, heat loss can be minimized, thereby enhancing energy efficiency within the kiln. Furthermore, their lightweight composition facilitates ease of handling and installation in the kiln. Nevertheless, it is crucial to carefully select insulating fire bricks that align with the unique operating conditions and demands of the cement kiln to guarantee utmost performance and durability.

- Q: Do insulating fire bricks have any insulating properties when wet?

- Insulating fire bricks do not have the same level of insulating properties when wet compared to when dry. The presence of moisture reduces their ability to retain heat and insulate effectively.

- Q: Can insulating fire bricks be used as insulation for pizza ovens?

- Indeed, insulation for pizza ovens can be achieved by utilizing insulating fire bricks. Designed to endure high temperatures and offer remarkable thermal insulation, these bricks possess a low thermal conductivity property, enabling them to efficiently retain heat and inhibit its escape from the oven. Consequently, this aids in upholding a steady and elevated temperature within the pizza oven, facilitating even cooking and achieving crispy crusts. Furthermore, insulating fire bricks are lightweight and simple to install, rendering them a favored option for insulating pizza ovens.

Send your message to us

Insulating Fire Brick - Refractory JM Mullite Insulation Brick B-7

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords