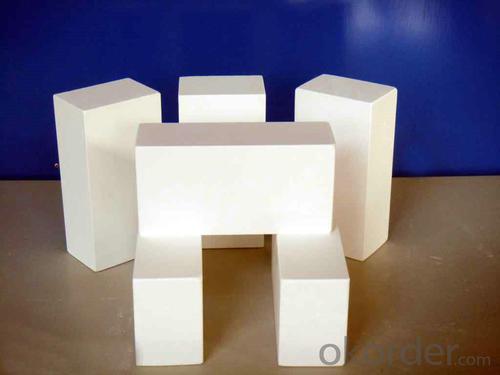

Insulating Fire Brick - Lightweight Insulation Refractory Clay for Industrial Furnaces

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Professional marketing team and after-sale service

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can insulating fire bricks be used in the construction of kilns?

- Yes, insulating fire bricks can be used in the construction of kilns. Their high insulating properties help to retain heat and improve energy efficiency in the kiln, making them a popular choice for lining the walls and floor of kilns.

- Q: Can insulating fire bricks be used in the construction of gas kilns?

- Indeed, it is possible to utilize insulating fire bricks in the construction of gas kilns. These bricks are specifically designed to possess low thermal conductivity, enabling them to retain heat effectively and enhance the kiln's energy efficiency. To guarantee the even distribution and maintenance of heat within the kiln chamber, proper insulation is necessary for gas kilns. By employing insulating fire bricks to line the walls, floor, and ceiling of the kiln, a barrier is created that aids in the prevention of heat loss and ultimately improves the kiln's overall performance. Furthermore, due to their lightweight nature and ease of handling, insulating fire bricks have become a favored choice for kiln construction projects.

- Q: What is the typical weight of an insulating fire brick?

- The typical weight of an insulating fire brick can vary depending on its size and composition, but it typically ranges from 2 to 4 pounds (0.9 to 1.8 kilograms).

- Q: Can insulating fire bricks be used in the construction of blast furnaces?

- Yes, insulating fire bricks can be used in the construction of blast furnaces. These bricks are made from lightweight materials with high thermal resistance, which makes them highly suitable for insulating the inner lining of blast furnaces. They help to minimize heat loss and maintain the high temperatures required for efficient and effective operation of the blast furnace, making them an essential component in its construction.

- Q: Can insulating fire bricks be used in the construction of hot air generators?

- Indeed, the utilization of insulating fire bricks is applicable in the fabrication of hot air generators. Specifically engineered to endure extreme temperatures and deliver exceptional thermal insulation, insulating fire bricks are well-suited for incorporation into hot air generators. These generators necessitate insulation to uphold elevated temperatures and avert heat dissipation. By diminishing heat transfer to the surroundings, insulating fire bricks effectively enhance the efficiency and functionality of hot air generators. Furthermore, their lightweight nature, effortless installation, and long-lasting durability contribute to their widespread adoption in diverse industrial sectors, including the construction of hot air generators.

- Q: What is the typical porosity of an insulating fire brick?

- The specific type and composition of an insulating fire brick influence its typical porosity, which can vary. Generally, insulating fire bricks have a porosity range of 40% to 70%. Porosity refers to the presence of open space or voids within the brick structure, which enhances its thermal insulation properties by minimizing heat transfer. The brick's insulation capability improves as its porosity increases. Manufacturers of insulating fire bricks typically target a specific porosity range to achieve the desired thermal conductivity and insulation efficiency.

- Q: Can insulating fire bricks be used in the construction of glassware molds?

- No, insulating fire bricks cannot be used in the construction of glassware molds. Insulating fire bricks are specifically designed for high-temperature insulation and are not suitable for molding glassware. Specialized materials like refractory or ceramic molds are commonly used for glassware molding due to their ability to withstand the high temperatures involved in the glass-making process.

- Q: Can insulating fire bricks be used in the construction of steam boilers?

- Yes, insulating fire bricks can be used in the construction of steam boilers. Insulating fire bricks are made from lightweight refractory materials that have excellent thermal insulation properties. They are designed to withstand high temperatures and provide insulation in industries where heat retention is crucial, such as steam boiler construction. Insulating fire bricks have low thermal conductivity, which means they can effectively minimize heat loss and improve energy efficiency in steam boilers. By using these bricks in the construction of steam boilers, the overall heat transfer efficiency can be increased, resulting in reduced fuel consumption and lower operating costs. Furthermore, insulating fire bricks have good resistance to thermal shock, meaning they can withstand rapid changes in temperature without cracking or breaking. This is important in steam boiler applications, where the temperature can fluctuate significantly during operation. In summary, insulating fire bricks are a suitable choice for steam boiler construction due to their excellent thermal insulation properties, low thermal conductivity, and resistance to thermal shock. They can help improve energy efficiency, reduce fuel consumption, and ensure the longevity of the boiler.

- Q: Are insulating fire bricks resistant to weathering or aging?

- Insulating fire bricks exhibit exceptional resistance to weathering and aging. These bricks are specifically engineered to endure extreme temperatures and harsh environmental conditions. They are composed of top-notch refractory materials, including alumina, silica, and other additives, which confer exceptional thermal insulation properties and strong resistance to corrosion and erosion. The manufacturing process of insulating fire bricks entails meticulous selection of raw materials and precise control of firing temperatures, resulting in a dense and homogeneous structure. This structure effectively prevents moisture and other weathering agents from infiltrating, thus ensuring extended durability and resistance to aging. Moreover, insulating fire bricks are also highly resistant to thermal shock, enabling them to withstand rapid temperature fluctuations without fracturing or disintegrating. This characteristic bolsters their ability to withstand adverse weather conditions. All in all, insulating fire bricks have demonstrated remarkable dependability in diverse applications that involve exposure to weathering elements. They find widespread usage in industries such as steel, ceramic, glass, and cement manufacturing, as well as in high-temperature applications like kilns, furnaces, and chimneys.

- Q: Are insulating fire bricks resistant to slag attack?

- Insulating fire bricks have a general resistance to slag attack. They are made from lightweight and porous materials, like alumina, silica, and other refractory materials. These bricks are designed to provide excellent insulation and high-temperature resistance in various industrial applications, such as furnaces, kilns, and incinerators. When we talk about slag attack, we are referring to the corrosion or erosion caused by molten slag. This slag is a byproduct of certain industrial processes, such as metal smelting or coal combustion. It can be highly corrosive and damage refractory materials, including fire bricks. However, insulating fire bricks are specifically formulated to resist slag attack. They have a composition and structure that allows them to withstand the corrosive nature of molten slag. This helps prevent erosion and maintain their insulating properties over time. Furthermore, insulating fire bricks can have different levels of slag resistance, depending on their specific composition and manufacturing process. Some fire bricks may even have additives or coatings to enhance their resistance to slag attack. It's important to note that while insulating fire bricks offer good resistance to slag attack, the severity and duration of exposure to slag can impact their performance. In highly corrosive environments or prolonged exposure to molten slag, even the most resistant fire bricks may eventually experience some degradation. Overall, insulating fire bricks are a reliable choice for applications where resistance to slag attack is necessary. However, it's always recommended to consult with a refractory engineer or supplier to ensure the appropriate selection of fire bricks based on the specific conditions and requirements of the industrial process.

Send your message to us

Insulating Fire Brick - Lightweight Insulation Refractory Clay for Industrial Furnaces

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords