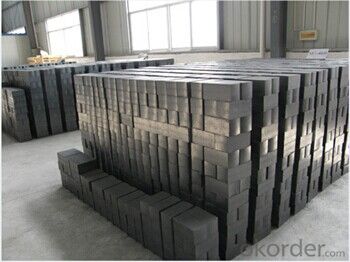

Insulating Fire Brick - Carborundum Refractory Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Passed ISO 9001;

2.57% Alumina content,or as customized;

3. Carborundum Fire Brick is widely used in iron-making.

AL2O3SiCC carborundum fire brick are universal materials for the lining of molten pretreatment equipments of molten iron tank, torpedo car, etc. The products are shaped by machine power by using dense bauxite clinkerand brown fused alumina as base materials and adding high quality SiC fines and high purity glake fraphite. It has the advantages of excellent slag resistance, thermal shock resistance, good resistance to mechanical erosion, abrasion resistance, etc.

Carborundum products belong to high grade refractory material,maximal use temperature is 1500°C,it has excellent thermal conductivity,heat shock stability,high load softening point and very good wear-resisting property,widely used in various industries with special requirement.

Item | Si3N4 bonded SiC brick | Sialon bonded SiC brick | Sialon bonded corundum brick | |

SiC, % ≥ | 72 | 70 | 80 (Al2O3) | |

Si3N4, % ≥ | 20 | 5 (N) | 5 (N) | |

Fe2O3, % ≤ | 0.7 | 0.7 | 0.7 | |

Bulk density g/cm3, ≥ | 2.65 | 2.65 | 3.1 | |

Apparent porosity %,≤ | 16 | 16 | 16 | |

CCS MPa, ≥ | 150 | 150 | 120 | |

MOR Mpa

| Room temp. ≥ | 42 | 42 | 12 |

1400°C×0.5hrs ≥ | 45 | 42 | 20 | |

Refractoriness under load °C ≥ (0.2MPa, 0.6%) | 1700 | 1700 | 1700 | |

Thermal shock resistance, cycles (Water quenching at 1100°C)≥ | 30 | 30 | 30 | |

- Q: Are insulating fire bricks resistant to vermin infestation?

- Despite their excellent insulation properties and widespread usage in high-temperature applications like fireplaces or kilns, insulating fire bricks are not specifically engineered to resist vermin infestation. It should be noted that vermin, including rats or mice, can still infiltrate the minute gaps or crevices present between these bricks. Furthermore, if the bricks are composed of softer materials like ceramic fiber or lightweight refractory materials, vermin can even gnaw through them. To effectively prevent vermin infestation, it is crucial to implement additional measures such as using appropriate sealants or mortar to seal any gaps or cracks between the bricks. Furthermore, conducting regular inspections and maintenance is highly recommended to promptly identify and address any indications of vermin activity.

- Q: Can insulating fire bricks be used in the construction of pizza ovens?

- Yes, insulating fire bricks can be used in the construction of pizza ovens. These bricks have excellent heat retention properties which help to create a high and even temperature inside the oven. Additionally, their insulating properties help to decrease heat loss, making them ideal for pizza ovens where maintaining a consistent and high temperature is crucial for achieving crispy and delicious pizzas.

- Q: Can insulating fire bricks be used for insulation in heat recovery systems?

- Indeed, insulating fire bricks have the capability to serve as insulation within heat recovery systems. These bricks are specially crafted to endure elevated temperatures and deliver efficient thermal insulation. By possessing low thermal conductivity, they possess the ability to reduce heat dissipation and enhance heat recovery within a system. Consequently, they are frequently implemented in diverse industrial settings, including kilns, furnaces, and ovens, where temperature regulation and energy efficiency are paramount. Therefore, these bricks present a viable option for insulating heat recovery systems, facilitating the optimization of waste heat recovery and utilization.

- Q: Are insulating fire bricks suitable for outdoor applications?

- Insulating fire bricks are generally unsuitable for outdoor use. They are designed for high-temperature environments like kilns, furnaces, and industrial settings, offering excellent thermal insulation and withstanding extreme heat. Nevertheless, insulating fire bricks are vulnerable to moisture, rain, and harsh weather conditions outdoors. They can easily be damaged and are not resistant to freezing and thawing, leading to cracks and breakage. For outdoor applications, it is advisable to opt for fire bricks specifically designed for such purposes. These bricks are typically made of dense clay or other materials that can endure moisture and weather conditions. They are more robust and offer superior protection against the elements. Before choosing the appropriate fire bricks for your outdoor needs, it is essential to take into account the specific requirements and conditions of your application. Seeking guidance from a knowledgeable professional or supplier in fire bricks can ensure that you select the suitable product for your requirements.

- Q: Are insulating fire bricks resistant to thermal expansion or contraction?

- Indeed, insulating fire bricks exhibit a remarkable resistance to thermal expansion and contraction. These bricks are composed of materials possessing minimal thermal conductivity, enabling them to endure elevated temperatures without experiencing substantial expansion or contraction. This characteristic renders them exceptionally well-suited for scenarios necessitating thermal stability and insulation, including kilns, furnaces, and various high-temperature settings.

- Q: Are insulating fire bricks resistant to erosion?

- Yes, insulating fire bricks are resistant to erosion.

- Q: Can insulating fire bricks be used in contact with molten metal?

- Indeed, it is possible to utilize insulating fire bricks in direct contact with molten metal. Specifically engineered to endure extreme temperatures, these bricks are widely employed in industrial settings where they encounter molten metal. With their exceptional resistance to thermal shock, they are capable of withstanding the intense heat generated by molten metal. Furthermore, insulating fire bricks possess low thermal conductivity, thereby reducing heat loss and enhancing energy efficiency. However, it is crucial to ascertain that the specific variant of insulating fire brick employed is suitable for the specific type of molten metal and temperature range it will be exposed to. Different metals possess varying melting points, which may necessitate the use of more specialized refractory materials.

- Q: Are insulating fire bricks resistant to fire?

- Absolutely, insulating fire bricks are resistant to fire without a doubt. These bricks are meticulously crafted and engineered to endure soaring temperatures and offer exceptional insulation properties. Made from lightweight refractory materials like ceramic fibers or expanded clay, insulating fire bricks possess low thermal conductivity and boast high melting points. Consequently, they excel at retaining heat and safeguarding against extreme temperatures. Their wide usage in furnaces, kilns, and fireplaces, where intense heat prevails, is a testament to their effectiveness. In essence, insulating fire bricks are tailor-made to be highly fire-resistant, making them an ideal choice for insulation against heat and fire prevention.

- Q: Can insulating fire bricks be cut to size?

- Indeed, it is possible to alter the dimensions of insulating fire bricks. Usually composed of lightweight refractory substances like expanded clay or vermiculite, insulating fire bricks are quite manageable to cut. Saws or knives are sufficient tools for this task. It is crucial to bear in mind that precautions should be taken while cutting insulating fire bricks to ensure safety. Wearing protective goggles and a dust mask is recommended due to the potential dust and small particles generated during the cutting process. Furthermore, it is advisable to either refer to the manufacturer's instructions or seek professional guidance to guarantee the correct technique and tools are employed for cutting insulating fire bricks.

- Q: Can insulating fire bricks be used for insulation in chemical storage tanks?

- Indeed, insulation in chemical storage tanks can be achieved by utilizing insulating fire bricks. These bricks, purposefully engineered to offer exceptional thermal insulation, lend themselves well to a wide range of industrial uses, including chemical storage tanks. Their outstanding insulating properties stem from their low thermal conductivity, ensuring minimal heat transfer and a consistent internal temperature within the tank. Moreover, these fire bricks exhibit remarkable resistance to high temperatures and the corrosive effects of various chemicals, rendering them a fitting option for insulation in chemical storage tanks.

Send your message to us

Insulating Fire Brick - Carborundum Refractory Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords