Diesel Driven Water Pump for Irrigation with Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

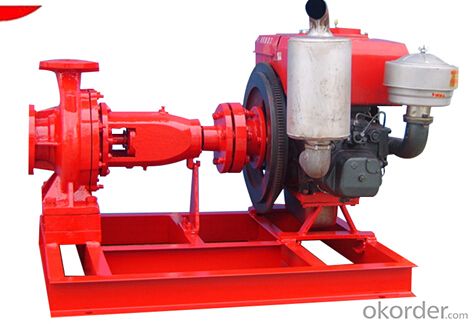

Diesel Driven Water Pump for Irrigation with Good Quality

1.Structure of Diesel Driven Water Pump for Irrigation Description

Diesel Driven Water Pump is used for transporting pure water or liquids with physical and chemical properties similar to pure water, and the maximum of the medium temperature is 80°C.(type ISR pump reaches 120°C). Widely applied towater supply industry, urban water supply and drainage, metallurgy, power stations, textile, chemical industry, printing and dyeing, ceramics, rubber, heating, waste heat utilization, air conditioning, agricultural irrigation and etc.

2.Main Features of the Diesel Driven Water Pump

• Compact structure, good appearance, low construction

•Operation stably, same inlet and outlet

•Convenient installation and maintenance

•Customized design is available, OEM and ODM are welcomed.

•Horizontally and vertically installation as different pipeline system

3. Diesel Driven Water Pump images

4. Diesel Driven Water Pump Specification

Item | Diesel Water Pump |

Diesel Pump | Agricultural Irrigation Desel Water Pump |

Model | IS |

Material | Cast iron |

Mode | Horizontal |

Color | Blue and adjustable |

Theory | Centrifugal Pump |

Structure | Single-stage Pump |

Usage | water |

Power | Electric |

Standard or Nonstandard | Standard |

Fuel | Diesel |

Pressure | High Pressure |

Application | Transporting pure water or liquids |

Outlet Diameter | 32-250mm |

Capacity | 6.3-400m3/h |

Head | 5-125m |

Rotation Speed | 1450-2900r/min |

Power | 0.55-110kW |

Warrenty | 1 Year |

Certificate | ISO9001 |

Feature | High efficiency,Easy maintenance |

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also

provide the pump model you are using now, price will be calculated as per the pump model, if not, we willrecommend relevant product for reference.

- Q: What are the causes of pump shock?

- 3. the water pump set screws loose, adjust the concentric, fastening the foot4. pump into foreign body, open cover overhaul5. the flow is too large or too small, adjust the equipment to control the water output

- Q: What is double hydraulic pump?

- Two hydraulic pumps installed on one shaft can be connected to increase output flow, and can also be connected to increase output pressure. See how the demand is. The system can change the mode of application at any time.

- Q: What are the characteristics of a vertical multistage centrifugal pump?

- Vertical multistage centrifugal pump system using the latest international advanced IS type hydraulic model based design for high efficiency centrifugal pump with multi segment, the soft packing or mechanical seal, has the characteristics of high efficiency, large flow, high lift, no leakage, a wide range of performance, safe operation, stable operation and long service life and small area.

- Q: What is a positive displacement pump? He Weizheng displacement?

- The principle and structure of positive displacement pumps are similar to those of hydraulic motors. Positive displacement is the pump outward to provide flow and pressure, that is, conventional pumps. A negative displacement pump is a hydraulic motor that rotates by external pressure and flow.

- Q: What does centrifugal pump mean horizontally?

- Centrifugal pump: centrifugal pump is a centrifugal force on the impeller rotates to transport liquid pump. Centrifugal pumps use the impeller to rotate and cause centrifugal motion of the water to work. The pump before starting to pump shell and the water pipe filled with water, and then start the motor, the pump shaft to drive the impeller and water do high-speed rotation, centrifugal water movement, was thrown to the outer edge of the impeller, the pressure water pipeline flow through the volute pump into the pump shell.

- Q: What are the main performance parameters of hydraulic pumps?

- speedOperating speed is the actual rotation speed of a pump (or motor) at work.Rated speed is the maximum speed that can operate normally for a long time under rated pressure. If the pump exceeds the rated speed, the work will cause insufficient oil absorption, vibration and noise, the parts will suffer cavitation damage, life expectancy.Minimum steady speed is the minimum speed allowed for normal motor operation. At this speed, the motor does not appear crawling phenomenon.

- Q: Pump operator's responsibility 10Sharing the rules, responsibilities, etc..

- 1., consciously abide by the traffic control department management rules, to achieve civilized driving, safe driving.2. responsible for the daily maintenance, cleaning and cleaning of the pump truck, and ensure the equipment is in good condition.

- Q: What is the main difference between SK water ring vacuum pump and 2BV water ring vacuum pump?

- SK vacuum pump is a single-stage water ring vacuum pump, vacuum pump and motor separation, coupled with couplings, vacuum relatively low.

- Q: How can I buy a pump?

- Selection principle of pump:1, so that the selected pump type and performance parameters meet the unit flow, lift, pressure, temperature and other requirements, the most important thing is to determine the voltage, the maximum lift, and when the head high reached much traffic.

- Q: What are the characteristics of the piston pump?

- main features 1 、 double plunger structure, small pressure pulsation, long life of gem ball.2 、 imported precious stones and precious stones to ensure accurate flow.3, through the RS232 interface and computer communication, can be directly controlled by the computer.

Send your message to us

Diesel Driven Water Pump for Irrigation with Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches