4x Sheets of Industrial Aluminium Profile 6000 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Industrial Aluminium Profile 6000 Series Description:

Industrial Aluminium Profile 6000 Series (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Industrial Aluminium Profile 6000 Series:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

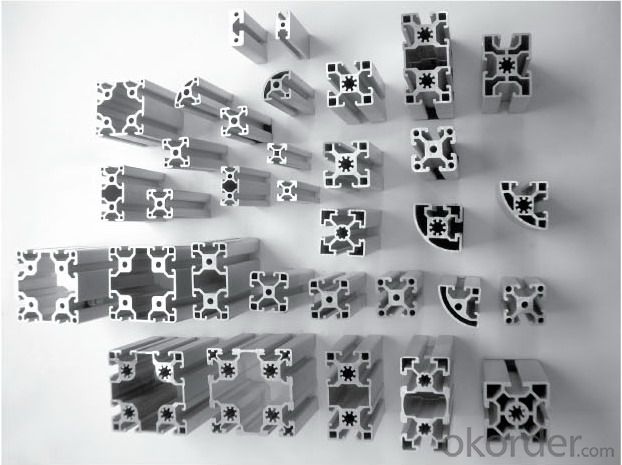

3.Industrial Aluminium Profile 6000 Series Images:

4.Industrial Aluminium Profile 6000 SeriesSpecification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different forms of aluminum sheet available?

- There are several different forms of aluminum sheet available on the market. These include: 1. Plain Aluminum Sheet: This is the most basic form of aluminum sheet, without any additional finishes or coatings. It is commonly used for general applications where appearance is not a major concern. 2. Painted Aluminum Sheet: This type of aluminum sheet is coated with a layer of paint or resin, which provides additional protection against corrosion and enhances the appearance of the sheet. It is often used for decorative purposes or in applications where aesthetics are important. 3. Anodized Aluminum Sheet: Anodizing is an electrochemical process that creates a durable and corrosion-resistant surface on the aluminum sheet. Anodized sheets have a uniform finish and are available in various colors. They are commonly used in architectural applications, such as building facades or interior design elements. 4. Perforated Aluminum Sheet: This type of aluminum sheet has small holes or perforations throughout its surface. It is often used in applications where ventilation, filtration, or aesthetics are important, such as in decorative screens, speaker grills, or air diffusers. 5. Embossed Aluminum Sheet: Embossing is a process that creates raised patterns or textures on the surface of the aluminum sheet. It adds visual interest and can also improve the sheet's strength and rigidity. Embossed aluminum sheets are commonly used in architectural or decorative applications. 6. Clad Aluminum Sheet: Cladding involves bonding a layer of aluminum to another material, such as stainless steel or copper, to combine their properties. Clad aluminum sheets are used in applications where the benefits of both materials are required, such as in the construction of heat exchangers or cookware. These are just a few examples of the different forms of aluminum sheet available. Each type offers unique properties and characteristics, making them suitable for various applications in industries such as construction, automotive, aerospace, and more.

- Q: I have heard that consuming aluminum can increase your risk for Alzheimer's later in life.Knowing this, would it increase my risk to eat sweet potatoes cooked in aluminum foil?Even if there is a negligible risk, I still want to know for curiosity reasons.Thank You

- You are not eating the aluminum foil when wrap food in it to cook. There is little transference of aluminum to the food you eat. When using it for baked potatoes, the skins just slide off so the potato meat itself had not contact with the foil. Though I have also read something on the use of aluminum cooking vessels and aluminum foil having some properties that can be dangerous to our health, I could find no articles from the FDA or other such qualified organizations regarding the use of aluminum foil.

- Q: What are the disadvantages of using aluminum sheets?

- Using aluminum sheets comes with several drawbacks. To begin with, aluminum is a relatively soft metal when compared to materials like steel. This softness makes it more susceptible to dents and scratches, which can negatively impact the sheet's overall appearance and structural integrity. Additionally, aluminum is a highly reactive metal, particularly in the presence of certain chemicals or harsh environments. This reactivity leads to corrosion, resulting in the formation of aluminum oxide, a white powdery substance. This corrosion weakens the sheet and compromises its durability. Furthermore, aluminum sheets are not as strong as steel sheets, rendering them less suitable for applications that demand high strength and stiffness. When dealing with heavy loads or extreme conditions, aluminum sheets may not provide the necessary structural support. Another disadvantage of aluminum sheets is their relatively high cost compared to other materials. The production process for aluminum involves energy-intensive steps, making it more expensive to manufacture. This cost can limit their use in projects with budget constraints. Moreover, aluminum sheets exhibit poor thermal and electrical conductivity when compared to metals like copper. This can be a disadvantage in applications where efficient heat transfer or electrical conductivity is required. Lastly, aluminum sheets have a lower melting point than steel, restricting their use in high-temperature applications. Subjecting aluminum sheets to high temperatures can cause them to weaken or deform, compromising their structural integrity. Overall, while aluminum sheets offer advantages such as being lightweight, corrosion-resistant, and versatile, they also come with several disadvantages that must be considered depending on the specific application.

- Q: Can aluminum sheets be formed into seamless tubes or pipes?

- Yes, aluminum sheets can be formed into seamless tubes or pipes. This is typically done through a process called extrusion, where the aluminum sheet is heated and forced through a die to form the desired shape. The extrusion process allows for the creation of seamless tubes or pipes with consistent dimensions and a smooth surface finish. Aluminum is a highly versatile and malleable material, making it suitable for various applications where lightweight and corrosion-resistant tubing is required.

- Q: The question asks if it is possible to recycle used aluminum foil to create new aluminum sheets.

- <p>Yes, recycled aluminum foil can be used to make new aluminum sheets. The process involves collecting and sorting the foil, which is then cleaned and melted down. The molten aluminum is poured into molds or rolled into sheets, creating new aluminum products. This recycling method is not only environmentally friendly but also economically viable as it saves energy compared to producing aluminum from raw materials.</p>

- Q: What is the atomic mass of aluminum?

- The atomic mass of aluminum is approximately 26.98 atomic mass units.

- Q: What is the difference between aluminum plate AL1050 and AL1060?

- 1050 and 1060 belong to an aluminum plate, that is, pure aluminum plate, the difference is that the content of aluminum is different. 1050 aluminum content 99.95%, 1060 Aluminum Content 99.60%, material is very close, often can replace the use, the current use is more than 1060 Aluminum plate.

- Q: How do you calculate the weight of an aluminum sheet?

- To calculate the weight of an aluminum sheet, you need to know the dimensions (length, width, and thickness) of the sheet and the density of aluminum. The weight can be calculated by multiplying these three values together and then multiplying it by the density of aluminum.

- Q: Are aluminum sheets suitable for thermal insulation?

- Aluminum sheets, by themselves, are not suitable for thermal insulation. Despite aluminum's ability to conduct heat and electricity well, it lacks sufficient insulating properties. Surprisingly, instead of blocking heat, aluminum sheets can actually transfer it, rendering them ineffective for thermal insulation purposes. To achieve proper thermal insulation, it is common to use materials with low thermal conductivity, such as fiberglass, mineral wool, or foam boards. These materials are specifically engineered to trap air or establish a barrier that minimizes heat transfer, thus ensuring efficient insulation.

- Q: Can aluminum sheet be used for food contact applications?

- Yes, aluminum sheet can be used for food contact applications. Aluminum is a widely used material in the food industry due to its excellent properties. It is non-toxic, corrosion-resistant, and has a high thermal conductivity, making it suitable for various food processing and packaging applications. Aluminum sheets can be used to make food containers, trays, and foils, providing a safe and hygienic option for food storage and transportation. Additionally, aluminum is recyclable, making it an environmentally friendly choice for food contact applications.

Send your message to us

4x Sheets of Industrial Aluminium Profile 6000 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords