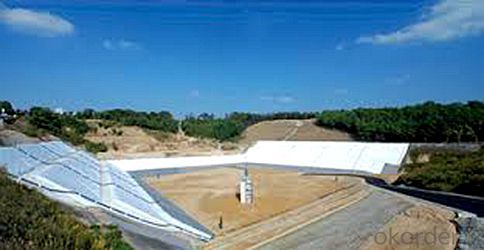

Geotextile Non Woven Fabric Impermeable HDPE Geomembrane for Architectural Pond

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Geomembrane

Classified by Material

1. HDPE Geomembrane

2. LDPE Geomembrane

3. LLDPE Geomembrane

Function: Waterproof

Application:

1. Environmental protection ( living landfill yard, sewage treatment plant, solid waste of industrial and hospital , etc.).

2. Protection of Water Resources ( anti-seepage, leakage blockage and reinforcement of river, lake, banks, anti-seepage of canal, side slope, etc.).

3. Municipal projects ( subway and underground engineering structures , anti-seepage of plantation roof and roof garden, lining of sewage pipe, etc.).

Feature:

1. Corrosion resistance, aging resistance, puncture resistance

2. Repairable and recyclable

3. Very low permeability

4. Good flexibility

5. Excellent environmental stress cracking resistance property

6. High tensile strength and elongation

7. For service temperature range : -70℃ ~ +110℃

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in green space development projects?

- Yes, geotextiles can be used in green space development projects. Geotextiles can provide various benefits such as erosion control, soil stabilization, and weed suppression, which are essential in creating and maintaining green spaces. By preventing soil erosion and promoting healthy plant growth, geotextiles contribute to the overall success of green space development projects.

- Q: Geotextile CBR tear strength rate is how much

- Geotextile CBR bursting strength is generally in accordance with the national standard GB / T-2017 "geosynthetics static top breaking test (CBR method)" according to the national standard GB / T-2017 standard requirements of geotextile CBR strong pre-tension 20N. According to the national standard GB / T-2017 standard requirements of geotextile CBR strong rate of (50 ± 5) mm / min.

- Q: What is the expected lifespan of geotextiles?

- The expected lifespan of geotextiles can vary depending on various factors such as the quality of the material, the specific application it is used for, and the environment it is exposed to. However, on average, geotextiles are designed to have a lifespan ranging from 10 to 30 years.

- Q: Can geotextiles be used in wastewater treatment applications?

- Yes, geotextiles can be used in wastewater treatment applications. They are commonly used in filtration systems to separate solids from liquids and provide support for various treatment processes. Geotextiles can enhance the efficiency of wastewater treatment by improving filtration, reducing clogging, and increasing overall system performance.

- Q: Long-term exposure to geotextiles on the human body what harm?

- Geotextile material is mostly polyester, and the essence of polyester clothes the same. There are mineral water bottle material is also PET polyester polyester sheet. Polyester has been widely used in our lives, no radiation, no pollution, no poison. Long-term close contact with the geotextile on the body without injury. So you do not have to worry.

- Q: Can geotextiles be used in the construction of underground storage facilities?

- Yes, geotextiles can be used in the construction of underground storage facilities. Geotextiles are commonly used in civil engineering projects, including underground structures, to provide reinforcement, filtration, drainage, and erosion control. In the case of underground storage facilities, geotextiles can be used to prevent soil erosion, enhance soil stability, and improve overall structural integrity.

- Q: What is the size of the filament geotextile? What are the characteristics of the application?

- What is the size of the filament geotextile? What are the characteristics of the application?

- Q: What are the different factors affecting the durability of geotextiles?

- There are several factors that can affect the durability of geotextiles, including exposure to UV radiation, chemical degradation, physical abrasion, moisture content, and temperature variations. Additionally, the quality and composition of the geotextile material, as well as proper installation and maintenance, can also impact its longevity.

- Q: What are the environmental considerations of geotextiles?

- Geotextiles have several environmental considerations that need to be taken into account. Firstly, the production of geotextiles requires the use of energy and raw materials, which can contribute to greenhouse gas emissions and depletion of natural resources. Additionally, the disposal of geotextiles after their useful life can pose a challenge as they are not easily biodegradable and can contribute to waste accumulation in landfills. However, geotextiles can also offer environmental benefits such as increasing soil stability, reducing erosion, and promoting better water management, which can help mitigate some of these concerns. Therefore, careful consideration of the environmental impacts and proper end-of-life management of geotextiles is crucial to minimize their negative effects.

- Q: What are the different geotextile installation techniques in erosion control?

- Some of the different geotextile installation techniques in erosion control include slope stabilization, sediment control, and shoreline protection. These techniques involve placing geotextile materials in strategic locations to prevent soil erosion, retain sediments, and protect vulnerable areas from wave action.

Send your message to us

Geotextile Non Woven Fabric Impermeable HDPE Geomembrane for Architectural Pond

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords