Hydraulic self climbing scaffolding、Hydraulic climbing protection platform

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

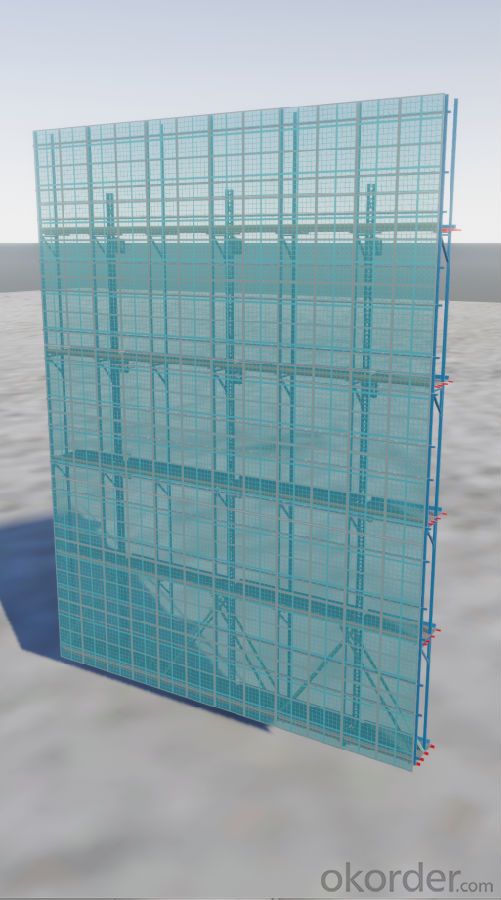

All-steel new type hydraulic climbing protective platform system

All-steel climbing will be upgraded on the basis of attached lifting all-steel climbing scaffolding, it will be applicable to any buildings: high-rise residential buildings, high-rise office buildings, industrial buildings, etc. With the development of the construction industry, all-steel climbing frame will directly replace the previous 70's and 80's domestic steel pipe scaffolding, steel pipe suspension scaffolding, disc buckle scaffolding, door type scaffolding,etc. All-steel climbing scaffolding has the advantages of low carbon, environmental protection, high turnover performance, high content of artificial intelligence science and technology, and low cost of project measures. With the increasing height of domestic market buildings, all-steel climbing scaffolding will play the most important role in high-rise building construction machinery.

Under the above background, many building developers pursue low-cost protective operation platform scaffolding under the condition of powerful function and good stability. In view of the above situation, we specially designed an improved hydraulic protection operation platform. As the main product in the unique climbing scaffolding market, compared with the conventional climbing protection platform system, the product simplifies the lifting components and lifting points, reduces the processing cost and simplifies the manufacturing process.

Change it into hydraulic cylinder type, and make a comparison on the basis that the whole building needs 50 seats. The investment of electric hoist is about 200,000 yuan. The special lifting components of climbing scaffolding system need 150,000 yuan. On this basis, additional electric and electronic control systems need about 100,000 yuan, so the cost of electric hoist system is 450,000 yuan. However, the whole building only needs two hydraulic cylinders and one pump station to realize the whole building's lifting operation. But it needs to divide 50 machine positions into 25 times for independent lifting. The actual cost of the system is 30,000 yuan. Therefore, under this background, the market and prospects of the hydraulic cylinder lifting operation protection platform can be realized.It has a decisive influence on the development of overseas market.

Technical features

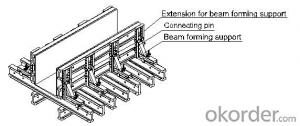

1、All-steel lightweight design, the frame structure can adapt to a variety of installation methods, it can be ground assembly or high-altitude structure installation.

2、All-steel material to avoid potential fire hazards.

3、Fully enclosed protection, internal construction work, safe and convenient.

4、The grouping design of frame structure can reduce the drawbacks of too much labor needed for climbing care because of the long perimeter of the building, simplify the workload of lifting and the labor input, and divide the climbing operation into several sections for pipeline construction.

5、Neat and beautiful appearance improves the civilized construction image. To be the scaffolding which saves your worry.

Item No | Project | Unit | Technical parameters | Remark | |

1 | Single machine-position size | Length | m | ≤5 | Sample machine: 5m×0.71m×18m Construe level height: H-3.8m |

2 | Width | m | 0.7-1.2 | ||

3 | Height | m | (3.5-5)H | ||

4 | Max span distance between machine-positions | m | ≤5 | ||

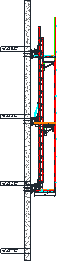

5 | Inner row vertical props distance from wall | m | ≤0.67 | ||

6 | Single machine-position power | KW | 1.5 | ||

8 | Single machine-position rated lifting weight | Kg | 5000 | ||

9 | Max construction loading | KN/㎡ | ≤2 | ≤3 Construction levels | |

10 | Single machine-position weight | Kg | 2800 | ||

11 | Lifting speed | mm/min | ≤100-400 | ||

12 | Single machine-position upper and bottom attached point distance | m | ≥H | ||

13 | Braking distance of anti-falling safety device | mm | ≤100 | ||

- Q: How is the hydraulic support moving

- Hydraulic support is a kind of hydraulic power unit which uses the liquid pressure to generate the support force and realize the automatic movement to carry out the roof support and management. It is an indispensable supporting equipment for comprehensive mechanized coal mining. Used to control the coal mining face pressure structure of the mine. The surface pressure is applied to the hydraulic support.

- Q: Climbing and floor scaffolding advantages and disadvantages

- Climbing frame, also known as lifting frame, according to its power source can be divided into hydraulic, electric, human hand pull and other major categories. It is developed in recent years, a new scaffolding system, mainly used in high-rise shear wall real estate. It can climb up or down along the building. This system makes the scaffolding technology completely changed: one is not to turn the shelf; the second is to remove the scaffolding disassembly process (after assembly has been used to complete the construction), and not subject to height restrictions on the building, a great savings in manpower And material. And in the security point of view for the traditional scaffolding has a greater improvement. In the high-rise buildings with great development advantages.

- Q: What is a climbing frame?

- Climbing frame, also known as lifting frame, according to its power source can be divided into hydraulic, electric, human hand pull and other major categories. It is developed in recent years, a new scaffolding system, mainly used in high-rise shear wall real estate. It can climb up or down along the building. This system makes the scaffolding technology completely changed: one is not to turn the shelves; the second is to remove the scaffolding of the dismantling process (after the assembly has been used to complete the construction), and not subject to height restrictions on the building, a great savings in manpower And material. And in the security point of view for the traditional scaffolding has a greater improvement. In the high-rise buildings with great development advantages.

- Q: Is the scaffolding scaffolding?

- Climbing frame, also known as lifting frame, according to its power source can be divided into hydraulic, electric, human hand pull and other major categories. It is developed in recent years, a new scaffolding system, mainly used in high-rise shear wall real estate. It can climb up or down along the building.

- Q: Climbing several, how is it running? And how much is the rental fee? Please explain in detail master! Thank you!

- Set the mounting platform --- Place the base, install the rails, assemble the horizontal truss parts - connect the beams to the rails with bolts and fasten the main frame to the beams - On the beam - the installation of wall-mounted device, the frame unloading to the guide seat --- with the structure connected to the elevated body, erected scaffolding, laying the middle layer or temporary scaffolding --- and the building structure to do temporary frame Pull the connection, hanging out the top of the safety net --- installed after the third beam, the installation of lifting seat and a layer with a wall guide block --- then the main frame of the main frame, the frame erected to the design height, Laying the top scaffolding plate, foot plate --- laying the bottom of the safety net and scaffolding, the production of flap - the upper frame and the structure of the effective pull-pull (pull-pull spacing of not more than 6m) --- hanging outside the row of dense security To the top of the frame --- the anti-fall boom inserted into the base anti-fall device, install the lifting wire rope --- placed electric control cabinet, distribution cable, install electric hoist, wiring, commissioning electrical system --- preload electric gourd, inspection and acceptance, with removal of the upper frame structure then pull, lift one synchronization --- fully installed, into Upgrade cycle

- Q: The difference between climbing and sliding mode

- Climbing is a short form of climbing template, also known as jumping abroad. It consists of climbing template, climbing frame (and some climbing no climbing) and climbing equipment composed of three parts, in the construction of shear wall system, the cylinder system and bridge pier and other high-rise structure is an effective tool. Because of the ability to self-climb, so no lifting machinery lifting, which reduces the construction of transport machinery lifting workload. Climbing scaffolds on self-climbing templates eliminates the need for external scaffolding during construction. In summary, climbing the template can reduce the number of lifting machinery, speed up the construction speed, so the economic benefits are better. Slip mode is a slow moving structure of the template, usually a fixed size of the stencil, drawn by the traction device.

Send your message to us

Hydraulic self climbing scaffolding、Hydraulic climbing protection platform

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords