Hydraulic Auto-Climbing Formwork for Buildings and Other Uses

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Hydraulic Auto-Climbing Formwork Description

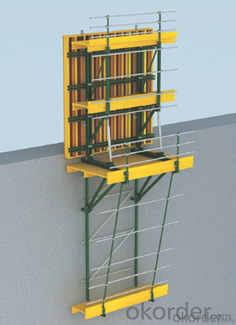

Hydraulic Auto-Climbing Formwork is mainly used in the concrete pouring of pier, high buildings, and so on. The concrete lateral pressure is entirely supported by anchor system and the wall-through tie-rods, additional reinforcement is not needed. The construction is easy, rapid and economical. A single pouring height is high and the finished concrete surface is perfect. Cantilever formwork has several types, the structure is similar, and has its own different characteristic. Can use them according to actual demand.

Main Hydraulic Auto-Climbing Formwork:PJ200 & PJ240,CB-240 etc.

2. Main Features of Hydraulic Auto-Climbing Formwork

-easy to assemble

-simple structure.

-easy, rapid and economical.

3. Hydraulic Auto-Climbing Formwork Images

4. Hydraulic Auto-Climbing Formwork Specifications

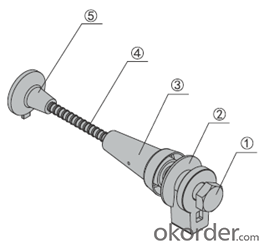

Anchor system

Anchor system is the most important supporting part. The system is made of five parts shown below. There into, tensile bolt, anchor shoe and bowl-climbing cone can be taken out for reusing after the concrete pouring.

① Tensile bolt M30/L= 110

② Anchor shoe

③ Bowl-climbing cone M30/D15

④ High-strength rod D15

⑤ Ancor plate D15

5.FAQ of Hydraulic Auto-Climbing Formwork

1) What can we do for you?

.We can ensure the quality of the Hydraulic Auto-Climbing Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- Regular inspection of the climbing device should check the connections. In particular, the following parts of the site to focus on inspection and reinforcement: according to the design requirements of the bolt with spring washers

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Install the lifting seat and a guide seat is connected with the high wall, main frame vertical rod, the frame set up to the designed height, laying the top scaffold, block feet - laying bottom safety nets and scaffolding, making turning plate - the upper part of the frame body structure and effective tie (tie spacing is not greater than 6m) - display efflux dense mesh safety net to the top of the shelf, the anti dropping boom is inserted into the base anti dropping device, the installation of steel rope - placed distribution cables, installation control cabinet, electric hoist, electric wiring and debugging system, pre inspection, electric hoist, demolition of frame body and the upper structure of pulling and synchronization a layer - installation completed, enter the upgrade cycle

- Q: The difference between the scaffold and the scaffold

- The difference between climbing frame and scaffolding is commonly used scaffolding from below has been set up, which is followed by building up climbing frame, the figure is upstairs, they have in common is that we are like scaffolding

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- Advantages and disadvantages of climbing frame and floor type scaffoldPjal | browse 5789Recommended 2016-09-21 09:11:21 best answerClimbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction. It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material. And in terms of security is also a big change for the traditional scaffolding. Highly developed in high-rise buildings. But it also has the disadvantage of fixed structure.

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- Climbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- And in terms of security is also a big change for the traditional scaffolding. Highly developed in high-rise buildings. Rental fees do not want the same

Send your message to us

Hydraulic Auto-Climbing Formwork for Buildings and Other Uses

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords