Formwork Girder Timber Beam for Concrete Formwork Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 3000 METER PER DAY m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

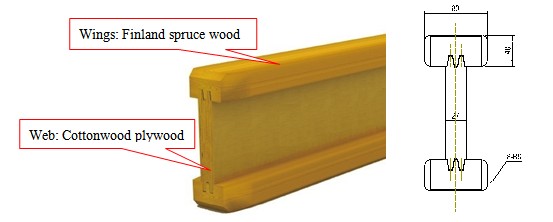

1.glued laminated timber beam

2.Max. Allowable shear force: 40KN, Max. Design value: 11KN;

3.Max. Allowable bending moment: 10KN·M, Max. Design value: 5KN·M.

Formwork Girder H20 Timber Beam for Concrete Formwork Construction Description:

1. Structure sketch

2. Related parameters

2. Related parameters

① Max. Allowable shear force: 40KN, Max. Design value: 11KN;

Max. Allowable bending moment: 10KN·M, Max. Design value: 5KN·M.

② Max. Production length: 6600mm;

Production capacity: 3000m/day;

Weight: about 4.8kg/m;

Moisture Content: about 13% ;

Using time: about 4-5 years.

Competitive Advantage:

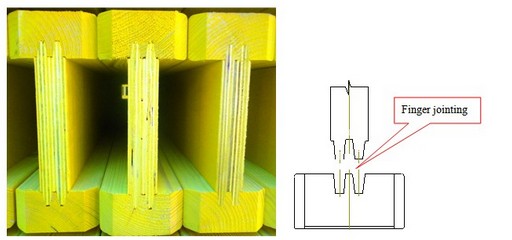

1. Standardized production line guarantees good products.

2. Finger jointing of the flange and web,the strength of timber beam is highly improved.

3. Well treated to prevent from water penetration or erosion, so the service life

maximally extended.

Normally, CMAX timber beam H20 can be used for 4 to 5 years, the exact using time is influenced by construction environment and the way to storage.

4. The length will be flexible, we can afford any length to meet customs’ demand within 6.6m limit.

Applications:

As a kind of girder, it is an important constituent part for formwork and it is widely used in concrete formwork construction.

Beam Timber:

1.material:poplar,pine,birch,hardwood

2.glue:WBP-phenolic,Melamine waterproof glue

3.usage:construction

Full Pine LVL H20 beam With High Quality :

1> if used abide by the illustrations strictly, it can be reused many times.

2> reducing the cost greatly and avoiding the disadvantage:restily and erosive of iron mould.

3>.solve the problems of leaking and rough surface during constructing process

4> .realizing a higher economic profies.

5> .new technology and materials are being introduced and popularized continuously for construction...........

Supply H20 beam--4 years experience, with competitive price and good quality, they are well selled in all around the world.

* Pine LVL flange + pine plywood web

* WBP phenolic resin

* Environment friendly Yellow painting: waterproof, fireproof, rot-proof and frozen-proof

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- Whether or not the double screw nut is used on the important bolt connection, the degree of the fastening, whether the steel bar is pressed according to the rules, and the steel wires are bundled together

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Climbing frame installation processInstallation of platform --- display base, installation guide, assembling components - horizontal truss beam with the bolt on the guide rail, the main frame vertical rod buckle on the beam - diagonal rod buckle on the vertical rod and beam - wall installation guide device, the frame structure of unloading with elevated body, the erection of scaffolding, the laying of the intermediate layer or temporary scaffolding and temporary building structure frame of pulling and hanging outside the dense mesh safety net - loaded third beams to guide seat -

- Q: The difference between the scaffold and the scaffold

- The difference between climbing frame and scaffolding is commonly used scaffolding from below has been set up, which is followed by building up climbing frame, the figure is upstairs, they have in common is that we are like scaffolding

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- 3, compared with the economy, the processing is simple, and the investment cost is low; if the geometric dimensions of the scaffold are carefully designed, and the utilization rate of the steel tube is improved, the material consumption can also obtain better economic effect. Fastener steel pipe frame equivalent to 15 square meters per square meter of construction steel.

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- And in terms of security is also a big change for the traditional scaffolding. Highly developed in high-rise buildings. Rental fees do not want the same

Send your message to us

Formwork Girder Timber Beam for Concrete Formwork Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 3000 METER PER DAY m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords