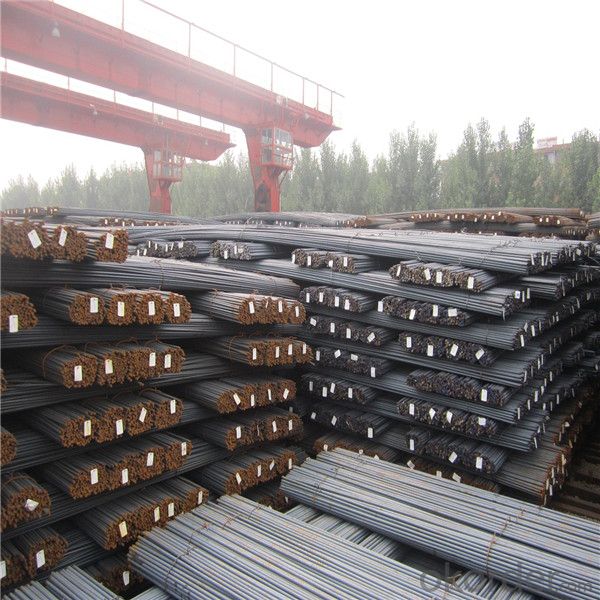

Rebar Steel Prices of China mill HRB400

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 19000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Rebar is common steel reinforcing bar, an important component of reinforced concrete and reinforced masonry structures.

It is usually formed from mild steel, and is given ridges for better frictional adhesion to the concrete.

Concrete is a material that is very strong in compression, but virtually without strength in tension. To compensate for this

imbalance in concrete's behavior, rebar is formed into it to carry the tensile loads.

.

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: What are steel rebars?

- Steel rebars, also known as reinforcement bars, are steel bars or rods that are used to strengthen and reinforce concrete structures. They are typically embedded within the concrete to provide tensile strength, preventing cracks and enhancing the structural integrity of buildings, bridges, and other infrastructure projects.

- Q: Can steel rebars be used in structures with high radiation shielding requirements?

- Structures with high radiation shielding requirements can indeed utilize steel rebars. Steel is renowned for its remarkable strength and durability, making it a favored option for reinforcing concrete structures. In terms of radiation shielding, steel rebars possess the capability to effectively offer a certain level of protection due to their dense composition. Although steel itself is not as potent a radiation shield as materials like lead or concrete, it still plays a role in reducing radiation transmission. The density of steel aids in dispersing and absorbing some of the radiation that passes through the structure, thus diminishing overall exposure. However, it is crucial to recognize that structures with exceptionally high radiation shielding requirements may necessitate additional measures. These measures could involve incorporating other radiation-absorbing materials such as lead or concrete, or implementing specific design features to enhance the structure's shielding capabilities. Ultimately, the selection of materials and design considerations should be made in collaboration with radiation safety experts and engineers who can evaluate the specific shielding requirements and propose the most suitable solutions.

- Q: How are steel rebars used in reinforcement cages?

- Steel rebars are used in reinforcement cages to provide structural strength and stability to concrete structures. They are placed strategically within the cage to enhance the overall durability and load-bearing capacity of the reinforced concrete elements.

- Q: How do steel rebars affect the aesthetics of a construction project?

- Steel rebars, being an essential component of reinforced concrete structures, do have an impact on the aesthetics of a construction project. While their primary function is to provide strength and reinforcement to concrete, their presence can influence the overall appearance of the project. One way steel rebars affect aesthetics is through their visibility. In most cases, rebars are left exposed during construction, especially in infrastructure projects such as bridges or parking garages. The exposed steel can create a unique industrial or modern look, which some consider aesthetically pleasing. This raw and utilitarian appearance can be intentionally embraced by architects and designers to achieve a specific aesthetic vision. However, in many architectural projects, especially those involving residential or commercial buildings, the visibility of steel rebars may not be desired. In such cases, rebars are typically concealed within the structure and covered by finishes such as concrete, plaster, or decorative cladding. By doing so, the aesthetics of the construction project can be enhanced, as the focus shifts from the structural elements to the overall design and finishes. Additionally, the placement and arrangement of rebars can also impact aesthetics. In intricate architectural designs, rebars may need to be precisely placed to achieve the desired structural integrity. This can pose challenges for designers as they strive to ensure both functionality and visual appeal. However, with careful planning and coordination, rebars can be strategically positioned to minimize their visual impact and maintain the desired aesthetics of the project. It is worth noting that aesthetics should not compromise the safety and structural integrity of a construction project. While efforts can be made to conceal or minimize the visual impact of steel rebars, their proper installation and adherence to engineering standards must always take precedence. Ultimately, the aesthetic impact of steel rebars on a construction project depends on the project's design intent, architectural style, and the balance between functionality and visual appeal.

- Q: How are steel rebars spliced or connected in construction joints?

- Various methods are used to splice or connect steel rebars in construction joints, ensuring the integrity and strength of reinforced concrete. A common method is lap splicing, where rebars are overlapped and then mechanically connected or tied together with steel wires or couplers. The required overlap length for lap splicing depends on the rebar diameter and design specifications, often specified as a multiple of the diameter. This length guarantees efficient load transfer and prevents potential failures at the connection point. Mechanical couplers offer an alternative method for splicing rebars. These pre-fabricated devices securely connect two rebars, eliminating the need for lap splicing and providing a more precise and reliable connection. Mechanical couplers are particularly useful when dealing with larger rebar sizes or when long lap lengths are not feasible. In certain cases, welded splicing may be used. This method involves welding the ends of rebars together, creating a solid and continuous connection. Welded splicing is commonly employed when dealing with larger diameter rebars and higher load requirements. However, it is crucial to adhere to proper welding techniques and practices to maintain the connection's integrity. Overall, the splicing or connection of steel rebars in construction joints is a crucial aspect of reinforced concrete construction. It ensures that rebars function as continuous reinforcement, enabling structures to effectively resist applied loads. The choice of splicing method depends on factors such as rebar size, design specifications, and project requirements.

- Q: How are steel rebars anchored into existing concrete?

- Steel rebars are typically anchored into existing concrete by using different methods such as epoxy adhesive, mechanical anchoring systems, or by simply embedding the rebars into the fresh concrete during construction.

- Q: Are steel rebars prone to rusting?

- Yes, steel rebars are prone to rusting. Rebars are made of carbon steel, which contains iron as its primary component. When exposed to moisture and oxygen, the iron in steel rebars undergoes a chemical reaction called oxidation, resulting in the formation of iron oxide or rust. This process can be accelerated in environments with high humidity, coastal areas with saltwater exposure, or when the rebars come into contact with water or other corrosive substances. The rusting of steel rebars can weaken their structural integrity and compromise the strength and durability of concrete structures. Therefore, it is essential to protect rebars from rust by applying anti-corrosion coatings or using stainless steel rebars in areas prone to rusting. Regular maintenance and inspection can also help identify and address any rust-related issues in a timely manner.

- Q: What is the role of steel rebars in preventing concrete creep?

- Steel rebars play a crucial role in preventing concrete creep by providing reinforcement and stability to the concrete structure. The rebars act as a framework within the concrete, distributing the tensile forces and preventing the concrete from deforming or cracking over time. Additionally, steel rebars help to control the shrinkage and expansion of concrete, minimizing the potential for creep and ensuring the long-term durability and integrity of the structure.

- Q: How do steel rebars contribute to the structural integrity of a building?

- Steel rebars play a crucial role in enhancing the structural integrity of a building. These reinforcing bars, commonly known as rebars, are typically made from steel and are used to provide strength and stability to concrete structures. They are embedded within the concrete to create a composite material that can withstand various types of forces and loads. Firstly, rebars help to distribute and transfer loads throughout the structure. When a building is subjected to external forces such as wind, earthquakes, or heavy loads, the rebars act as a reinforcement by absorbing and dispersing these forces. By distributing the load over a larger area, they prevent concentrated stress points that could potentially lead to structural failure. Secondly, rebars assist in preventing cracks and fractures in the concrete. Concrete, although highly durable in compression, is weak in tension. Steel rebars, with their high tensile strength, counteract this weakness by resisting the tensile forces that may cause the concrete to crack or fail. By reinforcing the concrete, rebars ensure that the structure remains intact and can withstand various types of stresses. Moreover, rebars increase the overall durability and lifespan of a building. By providing additional strength and stability, they reduce the likelihood of structural damage, ensuring that the building can withstand the test of time. This is particularly important in areas prone to natural disasters, where the strength of a building can be a matter of life and death. Lastly, steel rebars contribute to the overall safety of a building. By reinforcing the structure, they increase its ability to withstand extreme events such as earthquakes or heavy impacts. This not only protects the occupants of the building but also reduces the risk of collateral damage to surrounding structures. In conclusion, steel rebars are essential components in construction that significantly contribute to the structural integrity of a building. Their ability to distribute loads, prevent cracks, increase durability, and enhance safety make them an indispensable element in modern construction practices.

- Q: How do steel rebars resist abrasion in concrete structures?

- Steel rebars resist abrasion in concrete structures due to their high tensile strength and durable nature. The rough surface of the rebars provides better adhesion with the concrete, preventing slippage and ensuring a strong bond between the two materials. Additionally, the steel rebars act as reinforcement, distributing the load evenly and reducing the chances of cracks or spalling caused by abrasion or heavy impacts. Overall, the presence of steel rebars greatly enhances the durability and longevity of concrete structures.

Send your message to us

Rebar Steel Prices of China mill HRB400

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 19000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords