Hrb400 Deformed Steel Bar Supplier from Tianjin

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hrb400 Deformed Steel Bar Supplier from Tianjin

Description of Hrb400 Deformed Steel Bar:

1, Diameter: 5.5mm-10mm rounds Hrb400 deformed steel bar

10m- 40mm Hrb400 deformed steel bar

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

Chemical Composition of Hrb400 Deformed Steel Bar:

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

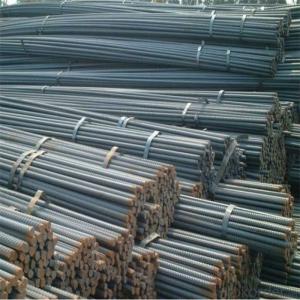

Product Show of Hrb400 Deformed Steel Bar:

Company Information:

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ:

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

- Q: What are the different low-temperature grades of special steel?

- Special steel includes several low-temperature grades designed to withstand extreme cold conditions. Among the commonly used grades are the following: 1. Austenitic Stainless Steel: This grade, such as 304 and 316, is renowned for its excellent corrosion resistance and high strength in low temperatures. It finds frequent use in cryogenic applications like LNG storage tanks and cryogenic piping. 2. Ferritic Stainless Steel: Ferritic stainless steel grades, including 410 and 430, possess good ductility and resistance to stress corrosion cracking, making them suitable for low-temperature applications. They are often utilized in cryogenic environments that require both high strength and resistance to embrittlement. 3. Martensitic Stainless Steel: Martensitic stainless steel, such as 410 and 420, delivers high strength and good toughness even in low temperatures. It is commonly employed in applications demanding exceptional wear resistance and strength, such as valves and turbine blades in cryogenic systems. 4. Duplex Stainless Steel: Duplex stainless steel grades like 2205 and 2507 combine high strength, excellent corrosion resistance, and good toughness in low temperatures. They are extensively employed in offshore and subsea applications where low-temperature performance and resistance to pitting and crevice corrosion are crucial. 5. Nickel-Based Alloys: Nickel-based alloys, such as Inconel and Hastelloy, are renowned for their exceptional corrosion resistance and high strength in both low and high temperatures. They are widely used in cryogenic applications, including liquefied natural gas (LNG) processing plants, as well as the aerospace and chemical processing industries. Each of these low-temperature grades of special steel offers distinct properties and advantages, making them suitable for various applications in extreme cold conditions. The appropriate grade selection depends on factors such as the specific temperature range, required corrosion resistance, strength requirements, and environmental conditions.

- Q: What are the main manufacturing processes for special steel?

- The main manufacturing processes for special steel include electric arc furnace (EAF) melting, vacuum degassing, continuous casting, hot rolling, heat treatment, and finishing operations such as machining and surface treatment. These processes ensure the production of high-quality specialized steel with desired properties and performance characteristics.

- Q: How does special steel perform under high temperatures?

- Special steel, also known as high-temperature steel, exhibits excellent performance under high temperatures. It maintains its strength, hardness, and resistance to deformation, making it suitable for various applications in extreme heat conditions. Additionally, special steel can withstand thermal stress and oxidation, ensuring its durability and reliability in high-temperature environments.

- Q: Is special steel suitable for manufacturing cutting tools?

- Yes, special steel is highly suitable for manufacturing cutting tools. Special steel refers to steel that has been specifically designed and processed to possess exceptional properties such as high hardness, toughness, and wear resistance. These characteristics make special steel an ideal choice for cutting tools as they enable the tools to withstand the high stresses and pressures involved in cutting operations. The hardness of special steel ensures that cutting tools can maintain their sharpness for a longer period of time, leading to improved cutting performance and efficiency. Additionally, the toughness of special steel allows cutting tools to resist chipping, cracking, or breaking during use, enhancing their durability and longevity. Furthermore, the wear resistance of special steel ensures that cutting tools can withstand the abrasive forces encountered during cutting operations without significant loss of material or deterioration. This helps to maintain the accuracy and precision of the cutting tools over time. Moreover, special steel can be tailored to meet specific requirements for different cutting applications. For example, high-speed steel (HSS) is a type of special steel that is particularly suitable for cutting tools used in high-speed machining operations. HSS possesses excellent heat resistance and can retain its hardness even at elevated temperatures. In conclusion, special steel is highly suitable for manufacturing cutting tools due to its hardness, toughness, wear resistance, and ability to be customized for specific cutting applications. These properties enable cutting tools to deliver optimal cutting performance, durability, and accuracy.

- Q: Can special steel be used in the production of jewelry?

- Indeed, it is possible to utilize special steel in the fabrication of jewelry. While precious metals such as gold, silver, and platinum are frequently employed in the art of jewelry making, there is an emerging inclination towards incorporating unconventional materials like special steel. The distinctive attributes of special steel, namely its durability, strength, and resistance to corrosion, allow for the creation of exquisite and intricate designs that cater to a contemporary and bold aesthetic. Moreover, special steel jewelry often presents a more economical alternative to traditional precious metal jewelry, rendering it a favored choice for individuals seeking a distinctive and budget-conscious option. Nevertheless, it is crucial to bear in mind that special steel jewelry necessitates proper care and maintenance to prevent tarnishing and scratching.

- Q: What are the properties of high-temperature steel?

- High-temperature steel possesses exceptional strength, heat resistance, and thermal stability, allowing it to retain its structural integrity even at elevated temperatures. It exhibits low thermal expansion and retains its mechanical properties under extreme heat conditions. Additionally, high-temperature steel is highly resistant to oxidation and corrosion, making it suitable for applications in industries such as aerospace, power generation, and manufacturing.

- Q: How is special steel used in the marine industry?

- Special steel is used in the marine industry for various applications due to its exceptional strength, corrosion resistance, and durability. It is commonly used for constructing ship hulls, propeller shafts, and other structural components that require high strength and resistance to harsh marine environments. Additionally, special steel is utilized in manufacturing marine equipment like anchors, chains, and offshore structures, ensuring their reliability and longevity.

- Q: What are the different methods of analyzing the microstructure of special steel?

- The microstructure of special steel can be analyzed using various methods. These methods involve examining and characterizing the steel at a microscopic level to gain insights into its composition, grain structure, and other features. Some commonly used methods include: 1. Optical Microscopy: By using light microscopy, the microstructure of special steel can be observed. This method allows for the identification of different phases, grain boundaries, inclusions, and other features. It provides valuable information about the size, distribution, and morphology of constituents in the steel. 2. Scanning Electron Microscopy (SEM): SEM is a powerful technique that utilizes a high-energy electron beam to analyze the microstructure of special steel. It offers detailed information about the steel's surface topography, morphology, and elemental composition. SEM is particularly useful for studying precipitates, segregation, and other microstructural defects. 3. Transmission Electron Microscopy (TEM): TEM is an advanced technique that enables analysis of the microstructure at a higher resolution compared to optical and SEM methods. It involves the transmission of electrons through a thin sample, providing information about the crystal structure, dislocations, and other fine details of the microstructure. TEM is especially beneficial for studying nanostructures and interfaces in special steel. 4. X-ray Diffraction (XRD): XRD is a non-destructive method that utilizes X-rays to analyze the crystal structure and identify phases in special steel. It provides information about the crystallographic orientation, grain size, and phase composition of the steel. XRD is widely used for analyzing phase transformations and residual stress in special steel. 5. Electron Backscatter Diffraction (EBSD): EBSD combines SEM with crystallographic analysis to provide information about the crystal orientation, texture, and grain boundaries in special steel. It is useful for studying deformation mechanisms, recrystallization, and grain growth in the steel. 6. Energy Dispersive X-ray Spectroscopy (EDS): EDS is often used in conjunction with SEM or TEM to analyze the elemental composition of special steel. It provides information about the presence and distribution of different chemical elements in the microstructure, aiding in the identification of phases and characterization of inclusions. These methods, among others, offer valuable insights into the microstructure of special steel. They enable researchers and engineers to understand the steel's properties, performance, and potential applications.

- Q: How does special steel resist wear and tear?

- Special steel resists wear and tear through its unique composition and heat treatment processes. It typically contains additives such as chromium, molybdenum, and vanadium, which enhance its hardness, corrosion resistance, and durability. Additionally, special steel undergoes specialized heat treatment techniques like quenching and tempering, which further improve its strength and ability to withstand stress and abrasion. These properties make special steel highly resistant to wear and tear, allowing it to maintain its structural integrity and performance over extended periods of use.

- Q: What are the applications of special steel in the agriculture sector?

- Special steel has various applications in the agriculture sector due to its exceptional properties such as durability, corrosion resistance, and strength. It is used in the manufacturing of farm equipment and machinery like tractors, plows, harrows, and combine harvesters. Special steel is also utilized in the construction of storage silos, irrigation systems, and animal housing structures. Additionally, it is employed in the production of cutting tools and blades for efficient crop harvesting and maintenance.

Send your message to us

Hrb400 Deformed Steel Bar Supplier from Tianjin

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords