HRB400 Tianjin Steel Rebar Manufacturer Supply Deformed Steel Rebar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,ASTM,JIS,GB,BS,DIN,API,EN

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series,300 Series,400 Series,600 Series,SS400-SS490,10#,20#,A53(A,B)

Certification:

ISO,SGS,BV,IBR,RoHS,CE,API,BSI,UL

Thickness:

6-34mm

Width:

6-34mm

Length:

12m

Outer Diameter:

6-34mm

Net Weight:

10kg

Packaging:

seaworthy packaging

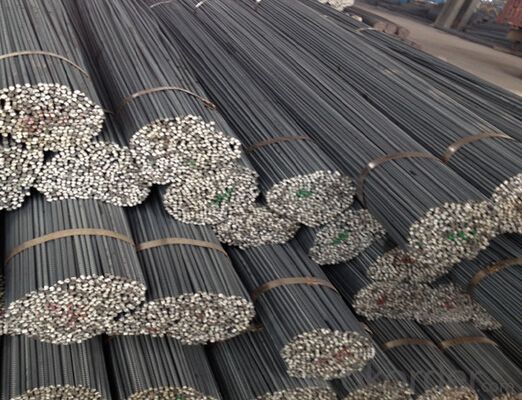

HRB400 Tianjin Steel Rebar Manufacturer Supply Deformed Steel Rebar

Details of the HRB400 Tianjin Steel Rebar Manufacturer Supply Deformed Steel Rebar

| Standard & Grade: | GB1499-98 : HRB335,HRB400,HRB500 |

| BS4449-1997 : GR460,GR500 | |

| CAN/CSA-G30.18-M92 : 400W | |

| ASTM A615 : Gr.40, Gr.60 | |

| Diameter: | 6mm;8mm;10mm;12mm;14mm;16mm;18mm;20mm;22mm;25mm;28mm;30mm;32mm;35mm;40mm |

| Length: | 6m,9m,12m |

| Packing: | Bundle packing |

| Origin: | China |

| Application: | Construction,Road,Machinery processing,Welding fields. |

| Delivery time: | 10-25 days |

| Shipment: | By bulk vessel or Container |

| Documents: | Mill Test Certificate,Commercial Invoice,Packing List,Certificate of Origin |

Company Introduction of the HRB400 Tianjin Steel Rebar Manufacturer Supply Deformed Steel Rebar

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of the HRB400 Tianjin Steel Rebar Manufacturer Supply Deformed Steel Rebar

| Packaging Detail | Sea worthy packing /as per customer's packing instruction |

| Delivery Detail | 15 ~ 40 days after receiving the deposit |

FAQ

| Are you a trading company or manufacturer? | Manufacturer |

| What’s the MOQ? | 1000m2 |

| What’s your delivery time? | 15-20 days after downpayment received |

| Do you Accept OEM service? | Yes |

| what’s your delivery terms? | FOB/CFR/CIF |

| What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

| Western Union acceptable for small amount. | |

| L/C acceptable for large amount. | |

| Scrow ,Paybal,Alipay are also ok | |

| Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

| What's your available port of Shipment? | Main Port, China |

| What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

| Where are your Market? | Covering more than 160 countries in the world |

- Q: What is the role of steel rebars in industrial chimney construction?

- Steel rebars play a crucial role in industrial chimney construction as they provide strength, stability, and durability to the structure. By reinforcing the concrete, rebars enhance the chimney's ability to withstand heavy loads, high temperatures, and harsh environmental conditions. They ensure the structural integrity of the chimney, preventing it from collapsing or cracking under stress. Furthermore, rebars help distribute forces evenly, reducing the risk of localized damage and ensuring the longevity of the chimney.

- Q: How do steel rebars contribute to the overall occupant comfort of a building?

- The overall occupant comfort of a building is greatly influenced by the role that steel rebars play in several ways. To begin with, steel rebars are essential for reinforcing concrete structures like walls, columns, and beams, providing the building with stability and strength. This ensures that the structure can withstand external forces such as wind, earthquakes, or heavy loads, without compromising the safety of the occupants. Additionally, the reinforced concrete helps to reduce vibrations, minimizing any discomfort caused by movement or shaking of the building. Moreover, the use of steel rebars enhances the building's durability and prevents cracks and deterioration over time. This is crucial in maintaining a comfortable indoor environment as it prevents issues like water leaks, moisture penetration, and the growth of mold or mildew. By avoiding these problems, steel rebars contribute to creating a healthy and comfortable living space for the occupants. Furthermore, steel rebars are commonly employed in the construction of high-rise buildings, which are susceptible to thermal expansion and contraction. By reinforcing the concrete structure, steel rebars assist in minimizing the effects of temperature changes, reducing the risk of structural damage, and ensuring a consistent indoor temperature. This, in turn, helps to create a comfortable environment for the occupants, regulating the temperature and preventing drafts or heat loss. Additionally, steel rebars also play a crucial role in fire resistance. Concrete structures reinforced with steel rebars have a higher fire resistance compared to other materials. This is due to the fact that steel has a high melting point and does not burn, providing occupants with extra time to evacuate the building in the event of a fire. This increased fire resistance contributes to the overall occupant comfort by enhancing their safety and reducing the risk of injuries or fatalities. In conclusion, the use of steel rebars significantly contributes to the overall occupant comfort of a building by providing stability, durability, thermal regulation, and fire resistance. Their role in reinforcing concrete structures ensures the safety, longevity, and functionality of the building, ultimately creating a comfortable and secure environment for the occupants.

- Q: Are there any specific safety guidelines for working with steel rebars?

- Yes, there are specific safety guidelines for working with steel rebars. Some of the key safety measures include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots. Workers should also be trained on safe handling techniques to avoid injuries from sharp edges or falling rebars. It is important to ensure a safe working environment by properly storing and stacking rebars, securing them to prevent movement, and using caution when cutting or bending them. Regular inspections and maintenance of tools and equipment are also essential for safety.

- Q: Are steel rebars affected by magnetic fields?

- Yes, steel rebars can be affected by magnetic fields. Steel is a ferromagnetic material, which means it can be magnetized or affected by external magnetic fields.

- Q: What are the guidelines for handling and disposing of steel rebars after demolition?

- To handle and dispose of steel rebars after demolition, the following guidelines should be followed: 1. Identify the steel rebars by appropriately marking or labeling them to distinguish them from other construction debris. 2. Separate the steel rebars from other waste materials on-site to ensure proper handling and recycling or disposal. 3. Take care during the demolition process to minimize damage to the steel rebars. Use suitable tools and techniques to avoid excessive bending or cutting, which can impact their recyclability. 4. Carefully remove the steel rebars from the site after demolition and transport them to the designated area for further processing or disposal. The method of removal and transportation will depend on the quantity and size of the rebars, and may involve machinery or manual labor. 5. Whenever possible, send the steel rebars to a recycling facility as they are highly recyclable. These facilities can process the rebars and convert them into new steel products, reducing the need for extracting and manufacturing new materials. 6. If recycling is not feasible, dispose of the steel rebars in accordance with local regulations. This may involve taking them to a designated landfill or waste disposal site that can handle construction materials. 7. Follow safety precautions when handling steel rebars, such as wearing appropriate personal protective equipment (PPE) like gloves and safety glasses. Additionally, use proper lifting techniques to prevent injuries. 8. Ensure compliance with local, state, and federal regulations for all handling and disposal activities. This may include obtaining necessary permits or licenses and adhering to specific waste management and recycling guidelines. By adhering to these guidelines, the handling and disposal of steel rebars after demolition can be conducted in an environmentally responsible and safe manner, contributing to sustainable construction practices.

- Q: What is the average lifespan of a reinforced concrete structure with steel rebars?

- The average lifespan of a reinforced concrete structure with steel rebars can vary depending on various factors such as the quality of construction, maintenance, exposure to environmental conditions, and usage patterns. However, with proper design, construction, and maintenance, reinforced concrete structures with steel rebars can have an average lifespan of 50 to 100 years or more. Reinforced concrete structures are known for their durability and strength due to the combination of concrete and steel reinforcement. The concrete provides compressive strength, while the steel rebars provide tensile strength, making the structure resistant to various loads and forces. However, over time, reinforced concrete structures may experience degradation due to factors such as exposure to moisture, chemicals, temperature changes, and loading conditions. These factors can lead to the corrosion of steel rebars, which is a common concern for the longevity of such structures. Corrosion occurs when moisture and oxygen penetrate the concrete, causing the steel rebars to rust. This rusting process can lead to the expansion of the steel rebars, causing cracks in the concrete and further accelerating the deterioration of the structure. To mitigate the effects of corrosion and extend the lifespan of reinforced concrete structures, various measures can be taken. These include using high-quality concrete and steel rebars, applying protective coatings, implementing proper drainage systems, and conducting regular inspections and maintenance. With appropriate maintenance and upkeep, reinforced concrete structures can last well beyond their average lifespan. However, it is crucial to note that the lifespan can vary depending on specific conditions and circumstances. Therefore, it is essential to consult with structural engineers and industry professionals to assess and determine the expected lifespan of a particular reinforced concrete structure.

- Q: Can steel rebars be used in historical monument conservation?

- Yes, steel rebars can be used in historical monument conservation. Steel rebars are commonly used in the restoration and strengthening of historical structures as they provide structural support and ensure the stability and longevity of the monument. However, it is essential to carefully analyze the impact of their installation on the historical value and authenticity of the monument. The use of steel rebars should be done in a way that minimizes any visual or aesthetic alterations to the monument, while still ensuring its preservation.

- Q: What is the process of straightening steel rebars?

- The process of straightening steel rebars involves using specialized machinery or tools to remove any bends or deformations in the rebars. This typically includes clamping the rebars in a straightening machine or using hydraulic forces to gently bend them back into their original shape. The rebars are carefully aligned and straightened to meet the required specifications, ensuring their structural integrity and effectiveness in construction projects.

- Q: Can steel rebars be used in structures with limited accessibility?

- Yes, steel rebars can be used in structures with limited accessibility. Steel rebars are commonly used in reinforced concrete structures to provide strength and durability. They are versatile and can be easily transported and installed even in areas with limited accessibility. In such situations, steel rebars can be cut, bent, and assembled on-site to fit the specific requirements of the structure. Additionally, steel rebars can be prefabricated off-site and then transported to the construction site, allowing for easier handling and installation in areas with restricted access. This makes steel rebars a suitable choice for structures in remote locations or areas with limited space.

- Q: What are the different types of coating for steel rebars?

- Steel rebars can be protected against corrosion and made more durable by applying various types of coatings. These coatings include: 1. Epoxy Coating: Epoxy coating is commonly used for steel rebars as it offers excellent corrosion protection. To ensure a thick and long-lasting coating, epoxy coatings are typically applied in multiple layers. 2. Galvanized Coating: Galvanized coating involves covering the steel rebar with a layer of zinc, which acts as a strong barrier against corrosion and extends the rebar's lifespan. This coating can be applied through hot-dip galvanizing or electroplating processes. 3. Fusion-Bonded Epoxy Coating (FBE): Fusion-bonded epoxy coating is another popular choice. It entails applying epoxy powder to the rebar and then fusing it to the surface through heat. FBE coatings provide exceptional resistance to chemicals and corrosion. 4. Stainless Steel Coating: Steel rebars can be coated with stainless steel to enhance their resistance to corrosion. This is achieved through thermal spray, in which stainless steel particles are sprayed onto the rebar surface. 5. Polyethylene Encasement: Polyethylene encasement involves wrapping the steel rebar with a layer of polyethylene material. This coating acts as a physical barrier, protecting against moisture and chemicals that cause corrosion. Each type of coating offers unique advantages and is suitable for different applications. The choice of coating for steel rebars depends on factors such as the environmental conditions, desired lifespan, and specific project requirements.

Send your message to us

HRB400 Tianjin Steel Rebar Manufacturer Supply Deformed Steel Rebar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords