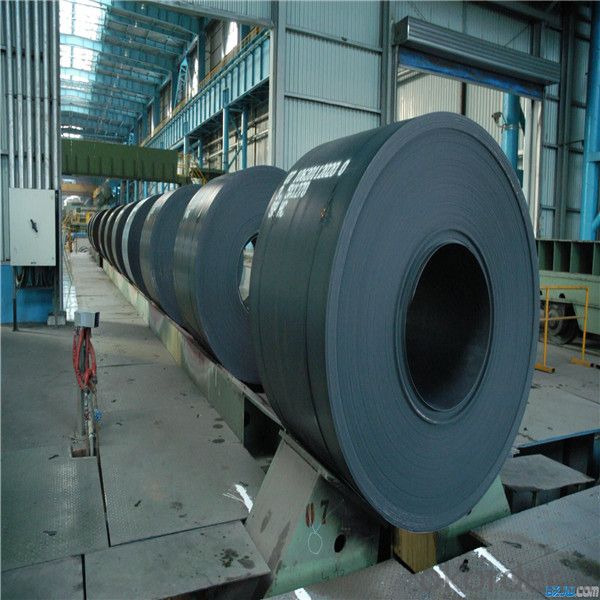

HR steel coils/Q235 Steel coils from steel company

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot Rolled Steel is widely available in the A36 steel alloy. The process to create Hot Rolled Steel creates a more ductile

steel with a rough surface finish and is sometimes more difficult to machine. The cost is usually much less than a similar Cold Rolled product. Hot Rolled Steel A36 comes in many shapes including: hot rolled steel flat bars, hot rolled steel flat bars,

hot rolled steel round bars, hot rolled steel square bars, hot rolled steel channels, hot rolled steel angles, and hot rolled tubing.

Order Hot Rolled Steel Alloys in A36 Hot Rolled Steel Alloys and Hot Rolled Stainless Steel Sheets in small quantities and no

minimums of all Stainless Steel at The Metal Store.

Uses: Hot rolled products like hot rolled steel bars are used in the welding and construction trades to make

railroad tracks and I-beams, for example. Hot rolled steel is used in situations where precise shapes and

tolerances are not required

Standard and Grade :

Hot rolled steel coils | ||||

JIS | ASTM | SAE | EN | |

Commercial quality | G3131 SPHC | A569 A635 A659 A1011 CS Type A,B,C | 1006~1025 |

10111 DD11 |

Drawing quality | G3131 SPHD | 1006~1010 | 10111 DD12 | |

Deep drawing quality | G3131 SPHE | A622 A1011 DS Type A,B | 1006~1010 | 10111 DD13 DD14 |

General structure (T.S.<490N/MM2) | G3101 SS330 SS440 G3106 SM400A G3132 SPHT1 SPTT2 SPHT3 | A36 A283 GR.C A570 GR.30~40 A1001 SS GR.30~40 |

1010~1025 | |

General structure (T.S.≥490N/MM2) | G3101 SS490 G3106 SM490A SM490YA | A570 GR.45~50 A607 GR.45~70 A1011 SS GR.45,50 |

J1392 050X | |

|

Application :

Automobile Industry, electrical appliance, machinery manufacturing, container manufacturing, shipbuilding,

bridge, pipeline, and receive high acclaim from our customers for its excellent quality.

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order..

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw

material to final product we have strict quality test;We resolutely put an end to unqualified products

flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the

factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the

shipment will depend on the vessel situation.

4.Q: What is your terms of payment ?

We prefer LC at sight and 30%T.T in advance ,balance after the copy of B/L

- Q: What are the common coil loading and unloading procedures?

- Common coil loading procedures involve using cranes or forklifts to lift and position coils onto trailers or flatbed trucks. The coils are typically secured using straps, chains, or coil racks to prevent shifting during transportation. During unloading, the same equipment is used to carefully lift and remove the coils from the truck, ensuring safety and stability throughout the process.

- Q: How are steel coils inspected for oil or rust residues?

- Steel coils are inspected for oil or rust residues through a series of visual and physical examinations. First, the coils are visually inspected by trained personnel who closely examine the surface of the steel for any signs of oil or rust residues. They look for discoloration, stains, or any other abnormalities that could indicate the presence of contaminants. In addition to the visual inspection, various techniques are used to detect oil or rust residues. One common method is the use of solvent cleaning. A solvent is applied to the surface of the steel coil, and if any oil or rust residues are present, they will dissolve and become visible. This allows the inspectors to identify and remove any contaminants. Another method used for inspection is ultrasonic testing. Ultrasonic waves are sent through the steel coil, and any variations in the waves' reflections can indicate the presence of oil or rust residues. This non-destructive testing method provides a deeper analysis of the condition of the steel, ensuring a more thorough inspection. Furthermore, specialized equipment such as magnetic particle inspection or eddy current testing may also be employed. Magnetic particle inspection involves applying magnetic particles to the steel surface, which will gather around any areas with oil or rust residues. Similarly, eddy current testing uses electromagnetic induction to detect surface irregularities caused by contaminants. Overall, a combination of visual inspection and various testing techniques is employed to thoroughly inspect steel coils for oil or rust residues. These rigorous inspections ensure that the coils meet the required quality standards and are free from any contaminants that could compromise their performance or durability.

- Q: Steel seems to be much less expensive. What is the reason why? I've heard steel will ruin a barrel after time....is that true? But with the price difference maybe it don't matter? Is steel reliable? What are the negatives about steel I should know before buying?

- Steel is a far more common thus cheaper metal than brass which is made of copper and zinc. The steel case stays in the firing chamber so does not do a thing to the barrel. It does have a different coefficient of expansion and when the gun gets hot it could jam in the chamber more than brass. Some of the steel has a lacquer coating on it that could gum up the works. The biggest disadvantage with steel is that as it is worked it gets weaker so reloading it is not real practical as you will get a lot of blown cases and head separations. In the long run you come out ahead buying brass and reloading than you do buying steel and throwing it away.

- Q: What are the different types of welding methods used for steel coils?

- There are several types of welding methods used for steel coils, including: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, it uses a flux-coated electrode to create an arc between the electrode and the base metal, forming a weld. 2. Gas Metal Arc Welding (GMAW): Also called MIG welding, it uses a continuous wire electrode and a shielding gas, typically argon or a mixture, to create a weld. 3. Flux-Cored Arc Welding (FCAW): Similar to GMAW, but instead of a solid wire electrode, it uses a tubular electrode filled with flux, which provides additional shielding and can be used with or without a shielding gas. 4. Submerged Arc Welding (SAW): It involves a continuous wire electrode and a granular flux that is fed under a layer of flux, creating a submerged arc and a highly efficient weld. 5. Resistance Welding: It utilizes electricity to generate heat and pressure, joining the steel coils together. Types of resistance welding include spot welding, seam welding, and projection welding. Each welding method has its own advantages and limitations, and the choice depends on factors such as the specific requirements of the steel coils, the thickness of the material, and the production process.

- Q: Does the solution change, or does only the steel wool change color?

- once you upload water to anhydrous copper(II) sulphate it turns blue because of the fact that's going to become hydrous copper(II) sulphate. Then, in case you upload water greater, that's going to proceed to be blue, could be slightly darker.

- Q: can steel boil and turn into a gaseous state?? if so how hot does it have to be for it to boil

- well what for yo? melting point of steel is 800 degrees, oxidation being 1400 degrees.

- Q: Can steel coils be coated with electrically conductive materials?

- Yes, steel coils can be coated with electrically conductive materials.

- Q: I am a beginner and have a slow to average swing speed. Should i get graphite or steel shafts for my irons and does it make a difference?

- How about graphite in your 3,4,5 irons and lightweight steel in your scoring clubs. You can swingweight them all the same so you will have a consistent feel through out the entire set and you will get extra help getting the ball in the air with the long irons and extra stability in the scoring clubs. And you save money by not having to put graphite in the entire set. As a beginner the clubs you get now may not suit you as you progress and your swing evolves so keep this in mind when buying a set of irons.

- Q: How are steel coils used in the production of steel screws?

- Steel coils are used in the production of steel screws as they serve as the raw material for manufacturing the screws. The steel coils are unwound and fed into a machine that cuts and shapes the steel into the desired screw form. This process ensures that the screws are made from high-quality steel and have the necessary strength and durability.

- Q: What are the different methods of pickling steel coils?

- There are several methods of pickling steel coils, including the use of acid pickling baths, electrolytic pickling, and pickle lines. Acid pickling baths involve immersing the steel coils in a bath of acid solution, such as hydrochloric or sulfuric acid, to remove scale and impurities from the surface. Electrolytic pickling uses an electric current to remove the scale from the steel coils, while pickle lines involve passing the coils through a series of acid baths and rinses to clean and prepare the surface for further processing.

Send your message to us

HR steel coils/Q235 Steel coils from steel company

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords