Galvanized Steel Sheet in High Quality Hot Selling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 7000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

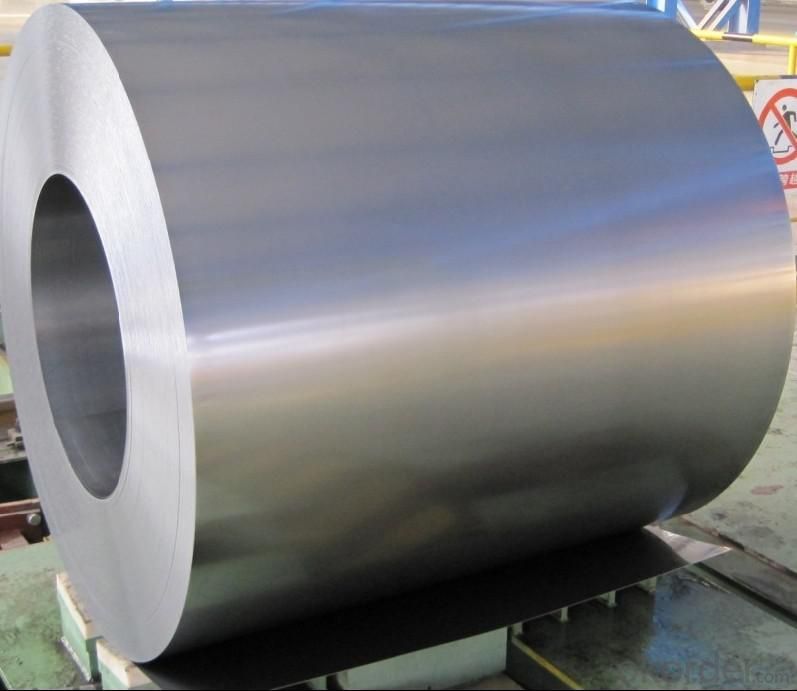

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

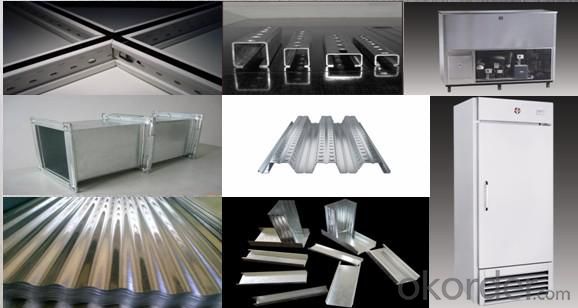

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

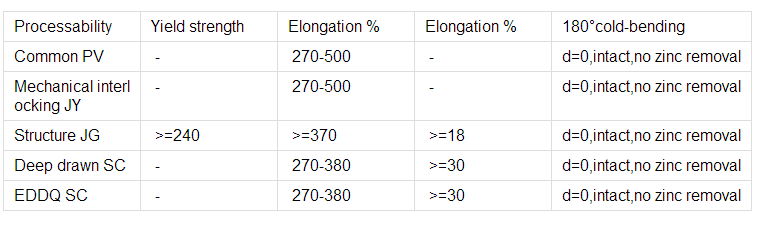

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What are the common coil surface finish standards?

- Some common coil surface finish standards include mill finish, brushed finish, polished finish, and coated finish.

- Q: Looking for an insight here into what hiking with steel toe-capped boots would be like, as I saw a nice pair of steel toed magnums that I plan to use for my future hiking (which I will be doing a fair amount of in the future). They seemed fairly comfortable, but I am curious into what others have to say and what might be known of this sort of approach. Thanks in advance.

- Steel toed boots are very heavy compared to hiking boots, after a long hike (especially in rough terrain) the extra weight is gonna tire you out. Steel toes are made for things like construction, or doing a task where extra protection of the toe is needed. So it's not ideal, but whatever floats your boat man (better than wearing tennis shoes). I personally have Converse composite toed boots from my airsofting days and since im too cheap to buy dedicated hike boots, I use it for hiking. Its supposedly made for military use and is much lighter than steel toe. But WAIT!!! lets say you dont have a gun or knife and you run into a pissed off Sasquatch, a steel toe boot too the nutz would do well in puttin the hurt on the dude.

- Q: What are the dimensions of steel coils used in the storage system industry?

- The dimensions of steel coils used in the storage system industry vary depending on the specific requirements of the storage system and the industry it is used in. However, common dimensions for steel coils used in storage systems can range from 0.15mm to 3.5mm in thickness, and from 600mm to 2100mm in width. The length of the coils can also vary, typically ranging from 1000mm to 6000mm.

- Q: What are the advantages of using steel coils over other materials?

- There are several advantages of using steel coils over other materials. Firstly, steel is highly durable and has a long lifespan, making it ideal for various applications. Secondly, steel coils have excellent strength and can withstand heavy loads and extreme weather conditions. Thirdly, steel is recyclable and environmentally friendly, ensuring sustainability. Additionally, steel coils provide superior corrosion resistance, reducing maintenance costs. Lastly, steel offers versatility in terms of customization, allowing for various shapes, sizes, and thicknesses to meet specific requirements.

- Q: What are the common applications of coated steel coils?

- The excellent properties and versatility of coated steel coils make them suitable for a wide range of applications in various industries. Some common uses of coated steel coils include: 1. Construction industry extensively employs coated steel coils for roofing, cladding, and wall panels. The coating ensures long-lasting structures by providing superior corrosion resistance, durability, and weatherability. 2. In the automotive industry, coated steel coils are widely used for manufacturing body panels, bumpers, and chassis parts. The coatings enhance aesthetics, protect against corrosion, and improve paint adhesion for a flawless finish. 3. Coated steel coils find utility in the production of household appliances like refrigerators, washing machines, and ovens. The coatings provide an attractive, smooth finish while protecting the steel from moisture and environmental factors. 4. Heating, Ventilation, and Air Conditioning (HVAC) systems commonly utilize coated steel coils for manufacturing ductwork, air handling units, and heat exchangers. The coatings ensure resistance against corrosion and improve system efficiency. 5. The furniture industry also makes use of coated steel coils for manufacturing cabinets, tables, and chairs. The coatings provide a decorative finish while protecting the steel from wear and tear. 6. Electrical equipment production, including switchboards, control panels, and enclosures, involves the use of coated steel coils. The coatings provide insulation and protection against electrical conductivity, ensuring durability. 7. In the packaging industry, coated steel coils are used for manufacturing cans, containers, and closures. The coatings act as a barrier against moisture and prevent contamination, ensuring the preservation and safety of packaged products. In conclusion, coated steel coils offer corrosion resistance, durability, aesthetics, and protective properties, making them suitable for various applications across industries. From construction to automotive, appliances to furniture, and even in electrical equipment and packaging, coated steel coils play a crucial role in delivering high-quality products and ensuring long-lasting performance.

- Q: Edward Humphrey wants to know... Can I use steel roofing on an older house?

- In the town that I live it is getting really popular.The good thing is the old roof doesn't need torn off you just put 2in boards the width or the steel on the old roof and then screw the steel roof panels to it.

- Q: What are the common coil widths and thickness combinations available for steel coils?

- The common coil widths and thickness combinations available for steel coils vary depending on the specific requirements and industry standards. However, there are some standard sizes that are commonly available in the market. For coil widths, the most common standard sizes range from 600mm to 2000mm. These widths are widely used in various industries such as automotive, construction, and manufacturing. However, custom widths are also available to meet specific project needs. As for the thickness combinations, steel coils are typically available in a range of thicknesses. The most common thicknesses for steel coils are between 0.4mm and 3mm. However, thicker or thinner options are available depending on the specific application. It is important to note that these standard sizes and thickness combinations may vary based on the specific steel grade, manufacturing process, and the supplier's capabilities. It is always recommended to discuss the required specifications with the supplier or manufacturer to ensure the availability of the desired coil widths and thickness combinations.

- Q: This question gets beat to death from what ive seen online but im going to ask it since im searching for a few new knives. The question is as the titles states what is the best steel for a general purpose knife? I plan on buying several different types of knives, Folders, fixed blades, ect. I will carry them around with me all the time for basically anything i can think of to use it for. The reason i ask this question here is because looking online everyone has a differnt veiw. Some say stainless is too soft while others say carbon will chip and is more brittle. Even looking at just a single type of steel, carbon fort instance everyone has a different opinion as to whats best leaving me kind of lost for what i should get. Maybe the better word would be What is a good general purpose steel?. Any advice is much appreciated!!!!

- There is no right one answer, because the term all purpose knife covers a very broad spectrum. The same knife that would be good for wood carving will not be the same for food prep, and will not be the same for general utility purposes. I'll just give you my humble opinion. For fixed blade, hard use blades. Where you will be doing bush tasks like chopping, carving etc... 1095 carbon is generally the standard. Now, 1095 is a great steel, it isn't the BEST steel. There are other steels that can outperform it. But for the price and availability its hard to beat. For folders, I prefer a decent stainless, like aus 8. It holds a good edge, and will hold up to any tasks you need a folding knife to do. Contrary to what you will read on the internet, stainless steel is not all crap. Its just that cheap stainless is just that, cheap. Stainless steel is only as good as its tempering process, some companies such as boker do amazing things with the steel and make for an impressive blade. Just stay away from crap stainless. So to sum up. 1095 for fixed blades. aus 8 for folders. These are both common steels used by different companies. If you get caught up on finding the perfect steel, you may overlook more important aspects of the knife itself. Unless your fixed blade is mostly going to be a food processing, and skinning knife, then I would suggest a QUALITY stainless as well. Remember that all high carbon blades need to be kept oiled or they will start to rust very fast. Btw, I suggest anyone looking into knives to check out mora fixed blades. Incredibly cheap, sharp and durable. They are the rockstars of bushcraft.

- Q: What are the standard dimensions and weights of steel coils?

- The specific type and grade of steel being used, as well as the manufacturing process and intended application, can cause variations in the standard dimensions and weights of steel coils. However, there are some common industry standards that can give a rough estimate of the dimensions and weights. In terms of dimensions, steel coils usually have a standard width that can range from 600mm to over 2000mm. The most commonly used widths are 1000mm, 1250mm, and 1500mm. The inner diameter of the coil, which is also known as the core or mandrel, is typically around 508mm (20 inches) or 610mm (24 inches). On the other hand, the outer diameter of the coil, which is known as the outside diameter or OD, can vary greatly depending on the thickness and width of the coil. However, it usually falls within the range of 1200mm to 2000mm. When it comes to weights, steel coils are measured by their gross weight, which includes the weight of the coil itself and the steel material it contains. The weight of a steel coil can vary from a few hundred kilograms to several tonnes, depending on the thickness and width. For example, a coil with a thickness of 0.5mm and a width of 1000mm may weigh approximately 5-6 tonnes, while a coil with a thickness of 3mm and a width of 1500mm can weigh around 20-25 tonnes. It's important to keep in mind that these dimensions and weights are general guidelines and may differ based on the specific requirements and standards of different industries and manufacturers. Therefore, it is advisable to refer to the relevant specifications or contact the manufacturer for accurate and up-to-date information regarding the dimensions and weights of steel coils.

- Q: How are steel coils used in the marine industry?

- Steel coils are commonly used in the marine industry for various purposes such as shipbuilding, offshore structures, and maritime equipment. These coils are utilized in the construction of ship hulls, decks, and bulkheads due to their high strength and durability. Additionally, they are often used in the fabrication of marine equipment such as cranes, winches, and anchor systems. Steel coils are crucial in ensuring the structural integrity and longevity of marine vessels and components, making them an essential material in the marine industry.

Send your message to us

Galvanized Steel Sheet in High Quality Hot Selling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 7000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords