Galvanized Wire Mesh - Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 3000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Galvanized Wire Mesh Description

It is widely used in the processing of oil,chemical,food,pharmaceutical and the sorting and screening of solid,liquid and gas in mine,metallurgy,airspace and machine making.

2.Main Features of the Galvanized Wire Mesh

•Made of high quality steel wire.

•Various configurations and sizes

•Used for loose strata to aviod falling rocks.

•Suitable for shotcrete applications.

•Range of sizes to suit roadway width and bolting patterns.

•Easy installation,

•Avaliable in black or hot dip galvanized.

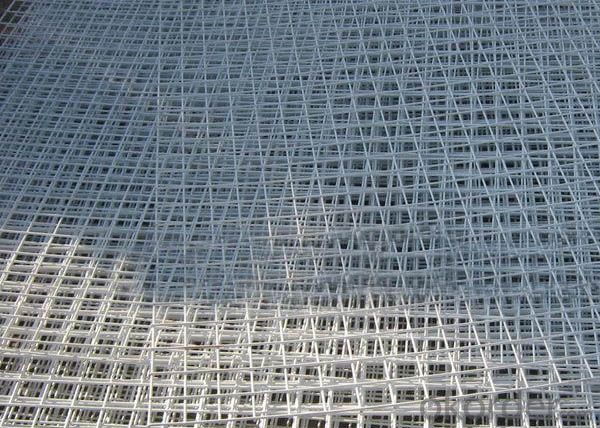

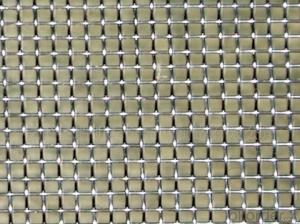

3. Galvanized Wire Mesh Images

4. Galvanized Wire Mesh Specification

| Standard | AISI, ASTM, BS, DIN, GB, JIS, etc |

| Grade | Q195, Q235, Q345, A36, SS400, 316, 304, etc |

| Width | 0.6-15m |

| Mesh Size | Wire Diameter |

| 1/4" x 1/4" | BWG 23 |

| 3/8" x 3/8" | BWG 19, 20, 21, 22 |

| 1/2" x 1/2" | BWG 16, 17, 18, 19, 20, 21, 22, 23, 24 |

| 5/8" x 5/8" | BWG 16, 17, 18, 19, 20, 21, 22 |

| 3/4" x 3/4" | BWG 16, 17, 18, 19, 20, 21, 22 |

| 1" x 1/2" | BWG 16, 17, 18, 19 |

| 1" x 1" | BWG 14, 15, 16, 17, 18, 19, 20, 21 |

| 1" x 2" | BWG 14, 15, 16 |

| 2" x 2" | BWG 14, 15, 16, 18 |

| 1-1/2" x 2" | BWG 14, 15, 16, 17, 18 |

| 3" x 3" | BWG 12, 13, 14, 15, 16, 17 |

| 2" x 4" | BWG 12, 13, 14, 16 |

| 4" x 4" | BWG 12, 13, 14 |

5.FAQ of Galvanized Wire Mesh

①The general use?

Welded Wire Mesh with excellent corrosion resistance and oxidation resistance, is extensively used as fencing, decoration and machinery protection material in agriculture, construction, transport, mine, sports field, lawn and various industrial fields

② Our Advantages?

1. Low cost for molding or tooling

2. Advanced & Standardization workshops and facilitates.

3. High-tech and high precision manufacturing equipment.

4. Strict ISO14001:2004 , ISO9001:2008 standards.

5. ROHS compliant & enviroment friendly products.

6. Professional technical specialists and management personel

7. 100% in house inspection before delivery

③Why you choose us?

We can make high precision parts from foil as thin as 0.025mm.

Main metal material we can photo etching including:

Stainless steel, iron, brass, copper, Kovar, Molybdenum

Surface can be paint color, gold/silver plated or mirror finish

Products can be made according to your drawing in .dxf or .dwg format.

Please feel free to contact us for the quotation

- Q: On the issue of their own screen printing

- Printed clothes must first have a printed version of the screen, clothing version with 120 or 130 mesh screen to do, with the version, scraper, ink, you can start printing color clothes need color, only one color

- Q: What are the reasons for the hair making of the screen plate?

- Exposure time is the most important, lack of time, after the version of the mucus to stay in the screen, affecting the printing edge, a long time, it is not easy to open the screen, it will be printed edge defects caused by burr.

- Q: How to get the correct fishing wire

- Screen (sticky net) used in a narrow place, the best night net, pay attention to the depth of water, the Internet is not too heavy too heavy. Can sink on the line.

- Q: Screen printing, how to print circular arc surface

- The cup is cylindrical, in the top of the screen will roll the cup, then the screen printing on the graphic part of the ink will be transferred to the cup.

- Q: The difference between screen printing characteristics

- Not subject to the size and shape of the substrate restrictions can only be printed on the plane, and silk screen can not only print on the plane, but also in the special shape of the molding and convex surface printing, but also can print a variety of large

- Q: Screen printing and screen printing plate on the photosensitive material What are the requirements

- posters, business cards, binding cover, product signs and printing and dyeing textile and other silk screen pollution process first plate production The use of ink in the developer is the production of ink bucket cleaning is to produce cleaning waste or waste wipe

- Q: How to clean the screen plate

- Directly with tap water rushed, and can be used with a cloth or soft brush brush. That the white mortar is water-based, then your screen board must also be water-based, so the fastest wash with tap water, the cost is the lowest, water-based stencil is not afraid of water, rest assured that red will not rot, unless you in the water Plus a release agent and the like. (But the water-based screen in the prepress are generally on the curing agent, or else is not easy to wash easily)

- Q: Screen printing, how to choose the screen

- Stainless steel screen printing network tension good strength high printing effect good for printing precision products such as solar panels circuit board printing

- Q: How to make screen printing layout smooth

- Complete the photosensitive / developed after drying and curing, and then in the layout of a layer of solvent-based paint, dry before the back with a vacuum suction pattern part of the transparent, no vacuum equipment, you can use paint thinner on the back

- Q: What are the characteristics of screen printing?

- Screen printing is widely used in China's electronics industry, ceramic decals industry, textile printing and dyeing industry and packaging and decoration, advertising, posters and other industries, as the screen printing is much more than other printing methods have many unique advantages.

Send your message to us

Galvanized Wire Mesh - Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 3000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords