Best Price For Aluzinc Steel Coil-JIS G3321

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 25mt m.t.

- Supply Capability:

- 5000mt/per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

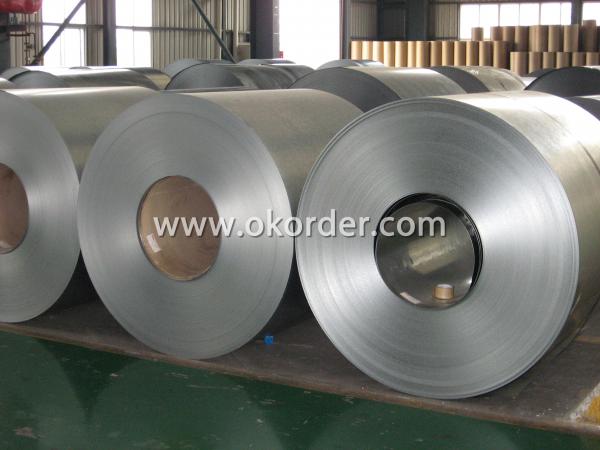

General Information Of Aluzinc Steel Coil JIS G3321

With Cold Rolled Steel as base metal,with the aluzinc coated, finally the plate steel is called galvalume steel. Galvalume steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

|

Thickness 0.25-4.0mm (BMT) |

|

Aluzinc Coating 50-150g/m2 |

|

Width 900-1250mm |

|

Internal Diameter 508mm or 610mm |

|

Coil Weight 4-8MT |

|

Quality Commercial and structural quality |

|

Surface Treatment Oiled or Dry, Chromated, Anti-finger,Non-skinpass,/ Skinpass |

|

Standard JIS G 3321, ASTM A792M, EN 10215 |

|

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD, S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Aluzinc Steel Coil JIS G3321

|

C |

Si |

Mn |

P |

S |

|

0.04-0.06% |

0.01-0.03% |

0.18-0.22% |

0.014-0.016% |

0.006%-0.009% |

Technical Data Of Aluzinc Steel Coil JIS G3321

|

Yield Strength |

(Mpa) 280-320 |

|

Tensile Strength |

(Mpa) 340-390 |

|

Elongation |

20%-30% |

|

Out- of-Square |

Not exceed 1% Flatness |

|

Bow |

15mm max |

|

Edge Wave |

9mm max |

|

Centre Buckle |

8mm max |

|

Bending At 180 Degree |

No crack, purling and fraction |

Application Of Aluzinc Steel Coil JIS G3321

Aluzinc Steel can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making roofing tile, steel profiles for wall partition, T-bar, studs, fireproof door, air conditioning duct and home appliances.

Packaging & Delivery Of Aluzinc Steel Coil JIS G3321

Full wrapped with anti-damped paper inside, iron sheet wrapped outside, and bundled with iron strips.

- Q: i am debating weather to get the hercules rmx or the steel and from what i have read, the only differences between them is the rmx has a sound card (built in interface-to connect to the computer, correct me if im wrong) and that the steel has more effects. however, i cannot find out which effects it has so it would be a big help if someone can answer this for me.thanx

- I guess that since Steel doesn’t have headphones connection and a built-in soundcard, one won’t be able to play a track on one deck and prelisten the track on the other without using an external usb soundcard, right? I was wondering what’s the point in releasing a product like this if you also have to buy a bunch of equipment to be able to do sth “fondamental”: play while preparing your next song. However since the steel is meant for DJ’s who already have a great soundcard, but I don’t see why a Steel+sound card is ONLY for pro’s. Yes it’s designed for pro’s but you can use it as a beginner. Some consoles you also need to consider: Hercules Steel/RMX, Numark OMNI/Steath. It's all personal decision. Peace, Love Happiness

- Q: I am doing a project on how revolvers work and what materials they use and would like to know what specific grade of stainless steel they use for the manufacturing of the frame and cylinder?

- *Rifle barrels are usually made from steel alloys called ordinance steel, nickel steel, chrome-molybdenum steel, or stainless steel, depending upon the requirements of the cartridge for which they are chambered. The higher the pressure and velocity of a cartridge (pressure and velocity usually go up together), the faster it will wear out a barrel. To give a satisfactory service life, barrels for high velocity cartridges must me made from tougher and harder steel than barrels for lower pressure cartridges. *The 400 (416) series SS commonly known as ordnance grade , is what barrels are made from . *If you want your barrel to be made from super alloy then it is 718 Inconel ,but a costly affair.

- Q: How is the critical temperature of structural steel affected by fireproofing? What temperatures can fireproofed structural steel withstand?

- I didn't know they fire proofed steel. Usally they would just use a steel with a higher melting point.

- Q: Are steel coils used in furniture manufacturing?

- Yes, steel coils are commonly used in furniture manufacturing. They are often used as a supportive framework in upholstered furniture, such as sofas and chairs, providing stability and durability to the overall structure.

- Q: I installed it, added it in F3 launcher and then after one minute of walking in wasteland I get a signal that Broken steel was added and that my level of caps was raised by 30. However after this message no quest is added. I played all 4 exp. packs and I had no problem at all, each time a new quest was added. So whats up with this Broken steel. Btw, I completed the entire game F3.

- Broken Steel doesn't begin until the main quest ends.

- Q: What are the different surface treatments available for steel coils?

- There are various surface treatments available for steel coils, including hot-dip galvanizing, electro-galvanizing, zinc plating, painting, powder coating, and organic coating.

- Q: I have a knife with AUS8 Stainless Steel. No idea what that means. I want to know some of the best stainless steels for knifes and all you can tell me about stainless steel would be great. I was browsing google and looking at grades and had no idea what all the numbers meant. Thanks!

- I do engraving on knife blades (actually all kinds of metal but occasionally knife blades). Every company's blades are a little different. I get the idea that different companies have different compounds. All the materials are some compromise between hardness, toughness, corrosion resistance, machineability and other considerations. Stainless is generally not as good as a high-carbon steel, but high-carbon steel rusts and turns black. Stainless is much easier to keep clean.

- Q: the comparison needed between other steel

- *Mild steel is ductile and can be easily machined. Generation of heat is less than that of steel machining.So, the tool can have better life and you can do more machining. Cost factor is of prime importance as other steel are more costly than Mild steel. Mild steel, a grade of steel that does not harden when heated and chilled with cold water, so further machining can be easy. Mild steel is easily available.You will find it in your scrape yard. No need to change the tool repeatedly and no special tools are required for machining. Above is the comparisation between alloy steel,SS and superalloys. Cutting speed and feed does not required special skills.

- Q: Alright...Please tell me what I can and can't buy for Steel Legion in detail(Much Detail please)Ogryns.Las canons.The problem I'm having is that they don't have steel Legion Uniform..does it matter?1.I also heard that you can't use Commisar Yarrick.(So what could I use?)2.What are my Hq choices,Fast attack,Heavy Support,Elite etc.3.Steel Legion has a Commisar....(Do I buy one for each squad of Steel Legion or one?)Please in detail what should I buy...I don't have the codex yet but will soon!!4.I also heard that if I get Steel Legion I need a transport for everything?(Is this true?)5.Please be detail on what i can't and can buy!!(Please like HQ Squad leader,Sargent)

- here are a couple of things about the steel legion. you should have a lot of mechanized units, have chimaras for rvery squad if posible, artillery fire helps a hell of a lot. also sentinals and leman russes and hell hounds also help. if in apocolypse, use banblades and titans. storm trooper squads should be your base squadrons. put them in chimeras and get near the action, drop 'em off and rapid fire like CRAZY!!! the steel legion loves heavy weapons so remember to get some heavy weapons platforms. there favourite weapons are grenade and missle launchers. there is also an officer you can buy with a power sword with the steel legion look. steel legion are big xeno hunters. because commisar is a ork killer you should be allowed to field him. ratling/ sniper squads also help and if you can get a vindicare assassin that is very useful.

- Q: Can steel coils be custom-made to specific requirements?

- Yes, steel coils can be custom-made to specific requirements. Steel manufacturers have the capabilities to produce steel coils with various dimensions, thicknesses, and specifications to meet the specific needs of customers. These coils can be customized in terms of width, length, weight, and even surface finish to suit specific applications and industries. Customization can also include variations in steel grade, coating type, and mechanical properties to ensure the desired performance and functionality. The ability to tailor steel coils to specific requirements allows for optimal utilization in various sectors such as automotive, construction, appliances, and manufacturing, among others.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1999 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Europe; Africa; Mid East; Southeast Asia |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 50-80 |

| Language Spoken: | Chinese, English |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Best Price For Aluzinc Steel Coil-JIS G3321

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 25mt m.t.

- Supply Capability:

- 5000mt/per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords