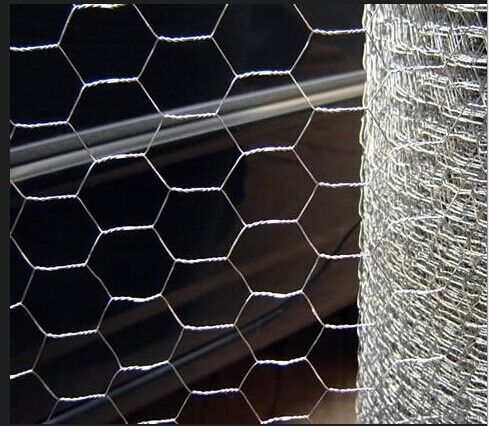

Aluminum Foil Facing Hot Sale Galvanized Chicken Hexagonal Wire Mesh Factory

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

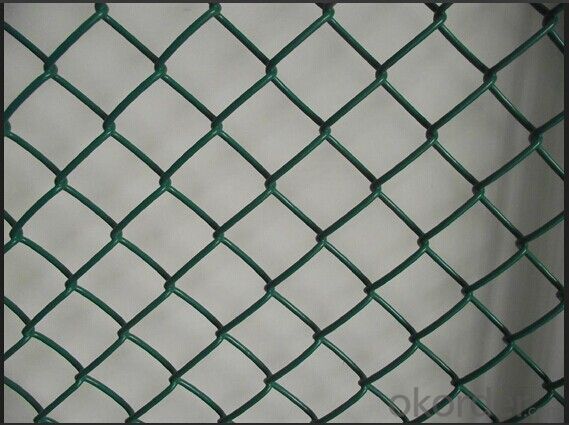

wire mesh

1. CE, ISO9001:2008

2. High Quality Low Price

3.Galvanized wire, PVC coated

4.Delivery: 10 days

Woven wire mesh

Stainless Steel Wire Mesh:

We produce stainless steel wire mesh from first class stainless steel wire material in SUS/AISI 201 202 302 304 310 310S 316 316L 321 430 etc.

Stainless steel wire mesh with its excellent resistance against acid, alkali, heat and corrosion, find extensively uses in processing of oil, chemical, food, making wire mesh filter, also sorting and screening of solid, liquid and gas in mine, metallurgy, airspace and machine making etc.

Stainless steel wire mesh | ||||||

mesh/inch | wire diameter mm | aperture mm |

| mesh/inch | wire diameter mm | aperture mm |

2mesh | 1.80 | 10.90 | 60mesh | 0.15 | 0.273 | |

3mesh | 1.60 | 6.866 | 70mesh | 0.14 | 0.223 | |

4mesh | 1.20 | 5.15 | 80mesh | 0.12 | 0.198 | |

5mesh | 0.91 | 4.17 | 90mesh | 0.11 | 0.172 | |

6mesh | 0.80 | 3.433 | 100mesh | 0.10 | 0.154 | |

8mesh | 0.60 | 2.575 | 120mesh | 0.08 | 0.132 | |

10mesh | 0.55 | 1.990 | 140mesh | 0.07 | 0.111 | |

12mesh | 0.50 | 1.616 | 150mesh | 0.065 | 0.104 | |

14mesh | 0.45 | 1.362 | 160mesh | 0.065 | 0.094 | |

16mesh | 0.40 | 1.188 | 180mesh | 0.053 | 0.088 | |

18mesh | 0.35 | 1.060 | 200mesh | 0.053 | 0.074 | |

20mesh | 0.30 | 0.970 | 250mesh | 0.04 | 0.061 | |

26mesh | 0.28 | 0.696 | 300mesh | 0.035 | 0.049 | |

30mesh | 0.25 | 0.596 | 325mesh | 0.03 | 0.048 | |

40mesh | 0.21 | 0.425 | 350mesh | 0.03 | 0.042 | |

50mesh | 0.19 | 0.318 | 400mesh | 0.025 | 0.0385 | |

Width of Stainless Steel Wire Mesh: 0.6m-1.5m | ||||||

Welded Wire Mesh

Reinforcing Mesh Panel Description:

1. Reinforcing Mesh Panel also named Welded Steel Bar panel or Heavy welded wire mesh panel.

2. Wire diameter of Weded Steel Bar Panel: 5mm -16mm

3. The opening of Welded Steel Bar Panel: 75mm-300mm

4. Reinforcing Mesh Panel length: 1m - 12m

5. Reinforcing Mesh Panel width: 100cm-240cm

6. Reinforcing Mesh Panel, Wire profile: Smooth profile, or ribbed profiile.

7. Reinforcing Mesh Panel, type of material: Q235

8. Reinforcing Mesh Panel Standard size: 2.4m x 6m

9. Australian Standard: SL72,SL82.

- Q: What are some safer alternatives to aluminum for food packaging?

- <p>Yes, there are several alternative materials for food packaging that are considered safer than aluminum. These include biodegradable materials like PLA (polylactic acid), which is derived from renewable resources like corn starch. Paper-based packaging is also a popular choice, often coated with wax or other materials for added protection. Additionally, glass containers are a non-toxic and reusable option. Some companies are exploring innovative solutions like mushroom-based packaging and edible packaging made from seaweed. These alternatives aim to reduce environmental impact while maintaining food safety and quality.</p>

- Q: Is it safe and practical to reuse plastic food wrap materials after cleaning them?

- <p>Reusing food wrap materials after washing them is generally not recommended. Plastic wraps can lose their effectiveness as barriers against bacteria and air after one use. Washing them can also introduce bacteria and may not fully remove any residual food particles. For food safety and hygiene, it's better to use new, clean wraps each time.</p>

- Q: Is it hazardous to cook acidic or salty foods with aluminum foil?

- <p>Using aluminum foil with highly acidic or salty foods is generally safe, but it's important to use the correct type of foil. Heavy-duty aluminum foil is designed for cooking and is safe for use with acidic and salty foods. However, avoid using aluminum foil with reactive metals, as it can cause a chemical reaction. Always follow cooking instructions and be cautious with prolonged cooking times or high temperatures, as these can potentially cause the foil to break down and release small amounts of aluminum into the food. For best results, opt for non-reactive cookware or use parchment paper or silicone baking mats as alternatives.</p>

- Q: This question asks for methods to prevent aluminum from aluminum foil leaching into food.

- <p>To avoid aluminum from aluminum foil leaching into your food, use the foil sparingly and avoid wrapping food directly in it. Opt for heavy-duty aluminum foil, which is less likely to tear and expose food to aluminum. When cooking acidic or salty foods, consider using parchment paper or silicone baking mats as alternatives. Additionally, avoid using aluminum foil at high temperatures, as this can increase the risk of aluminum transfer. Finally, store food in glass or stainless steel containers instead of aluminum foil to minimize exposure.</p>

- Q: This question asks for a method to clean aluminum foil after cooking to get rid of excess oil.

- <p>To remove excess oil from aluminum foil after cooking, first let the foil cool down to avoid burns. Then, you can use a paper towel or a clean cloth to gently wipe away the oil. For stubborn oil, you can wash the foil with warm soapy water. If you're reusing the foil, make sure it's thoroughly dried before storing to prevent any potential for bacterial growth. Always remember to handle aluminum foil with care as it can be sharp and may tear easily.</p>

- Q: Describe the process of aluminum foil facing in a few sentences.

- <p>Aluminum foil facing is a process used to laminate aluminum foil to a substrate, typically for decorative or functional purposes. The process begins with the preparation of the substrate, ensuring it is clean and free of contaminants. Then, a layer of adhesive is applied to the substrate. The aluminum foil is then placed onto the adhesive-covered substrate and pressure is applied to ensure proper adhesion. The laminated product is then cured, which can involve heat or UV light to set the adhesive. Finally, the product is trimmed and inspected for quality before being packaged and shipped. This process is used in various industries, including construction, automotive, and consumer goods.</p>

- Q: Explain the differences between food wrap and aluminum foil facing in a few sentences.

- <p>Food wrap, also known as plastic wrap, is a thin, flexible plastic film used to cover and preserve food, keeping it fresh and protected from contaminants. It's typically clingy and transparent, allowing you to see the food inside. Aluminum foil facing, on the other hand, is a type of laminate that has a layer of aluminum foil bonded to a plastic film. This facing is used for various purposes, including increasing the barrier properties of the plastic, providing a shiny appearance, and enhancing the product's durability. It's often used in packaging to protect and preserve food items, but it's not as clingy or transparent as food wrap and is not meant for direct contact with food in the same way.</p>

- Q: What are the advantages of using aluminum foil as a reflective surface in various applications, particularly in health contexts?

- <p>Using aluminum foil facing provides several health benefits, particularly in cooking and food preservation. It helps retain moisture in foods, reducing the need for added fats and oils, which can contribute to a healthier diet. Reflective aluminum foil can also help distribute heat evenly in ovens, ensuring food cooks more uniformly and reduces the risk of overcooking or burning. Additionally, it can help in food reheating, ensuring that food is heated evenly and thoroughly, which is important for food safety. In some cases, aluminum foil can also be used to create a barrier against harmful UV rays in tanning beds, although this is not recommended due to potential health risks associated with tanning. Overall, the use of aluminum foil facing can contribute to healthier cooking practices and food safety.</p>

- Q: Is it safe and effective to use aluminum foil facing for baking purposes?

- <p>Yes, you can use aluminum foil facing for baking. It's a common practice to line baking sheets with aluminum foil to prevent food from sticking and to make cleanup easier. However, ensure the foil does not come into direct contact with the heating elements of the oven as it can melt. Additionally, avoid wrapping food in aluminum foil for extended baking times at high temperatures, as it may lead to uneven cooking or potential health concerns from aluminum leaching into the food.</p>

- Q: The user is asking if aluminum foil can be used to make a pizza crust more flaky and tender.

- <p>Using aluminum foil facing on a pizza crust won't inherently make it more flaky or tender. The flakiness and tenderness of a pizza crust are determined by the ingredients used and the method of preparation. For a flakier crust, consider using a higher fat content like butter or shortening, and for tenderness, ensure proper hydration and kneading of the dough. Aluminum foil is typically used for its heat distribution properties and to prevent direct contact with the oven rack, which can help in browning the bottom of the crust. However, it doesn't affect the flakiness or tenderness directly.</p>

Send your message to us

Aluminum Foil Facing Hot Sale Galvanized Chicken Hexagonal Wire Mesh Factory

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords