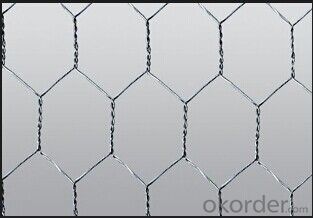

Aluminum Foil Facing Hexagonal Chicken Wire Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

wire mesh

1. CE, ISO9001:2008

2. High Quality Low Price

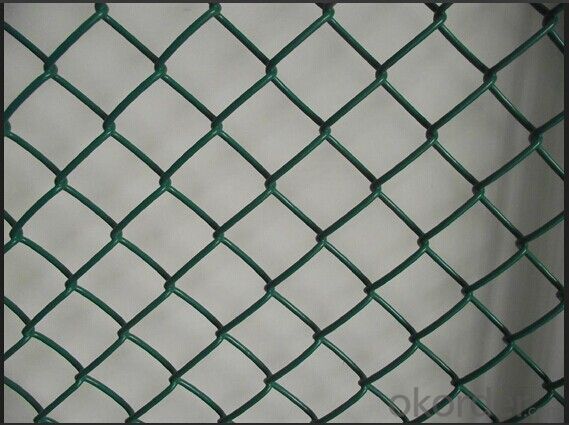

3.Galvanized wire, PVC coated

4.Delivery: 10 days

Woven wire mesh

Stainless Steel Wire Mesh:

We produce stainless steel wire mesh from first class stainless steel wire material in SUS/AISI 201 202 302 304 310 310S 316 316L 321 430 etc.

Stainless steel wire mesh with its excellent resistance against acid, alkali, heat and corrosion, find extensively uses in processing of oil, chemical, food, making wire mesh filter, also sorting and screening of solid, liquid and gas in mine, metallurgy, airspace and machine making etc.

Stainless steel wire mesh | ||||||

mesh/inch | wire diameter mm | aperture mm |

| mesh/inch | wire diameter mm | aperture mm |

2mesh | 1.80 | 10.90 | 60mesh | 0.15 | 0.273 | |

3mesh | 1.60 | 6.866 | 70mesh | 0.14 | 0.223 | |

4mesh | 1.20 | 5.15 | 80mesh | 0.12 | 0.198 | |

5mesh | 0.91 | 4.17 | 90mesh | 0.11 | 0.172 | |

6mesh | 0.80 | 3.433 | 100mesh | 0.10 | 0.154 | |

8mesh | 0.60 | 2.575 | 120mesh | 0.08 | 0.132 | |

10mesh | 0.55 | 1.990 | 140mesh | 0.07 | 0.111 | |

12mesh | 0.50 | 1.616 | 150mesh | 0.065 | 0.104 | |

14mesh | 0.45 | 1.362 | 160mesh | 0.065 | 0.094 | |

16mesh | 0.40 | 1.188 | 180mesh | 0.053 | 0.088 | |

18mesh | 0.35 | 1.060 | 200mesh | 0.053 | 0.074 | |

20mesh | 0.30 | 0.970 | 250mesh | 0.04 | 0.061 | |

26mesh | 0.28 | 0.696 | 300mesh | 0.035 | 0.049 | |

30mesh | 0.25 | 0.596 | 325mesh | 0.03 | 0.048 | |

40mesh | 0.21 | 0.425 | 350mesh | 0.03 | 0.042 | |

50mesh | 0.19 | 0.318 | 400mesh | 0.025 | 0.0385 | |

Width of Stainless Steel Wire Mesh: 0.6m-1.5m | ||||||

Welded Wire Mesh

Reinforcing Mesh Panel Description:

1. Reinforcing Mesh Panel also named Welded Steel Bar panel or Heavy welded wire mesh panel.

2. Wire diameter of Weded Steel Bar Panel: 5mm -16mm

3. The opening of Welded Steel Bar Panel: 75mm-300mm

4. Reinforcing Mesh Panel length: 1m - 12m

5. Reinforcing Mesh Panel width: 100cm-240cm

6. Reinforcing Mesh Panel, Wire profile: Smooth profile, or ribbed profiile.

7. Reinforcing Mesh Panel, type of material: Q235

8. Reinforcing Mesh Panel Standard size: 2.4m x 6m

9. Australian Standard: SL72,SL82.

- Q: This question asks for clarification on the distinction between two types of aluminum products: aluminum foil facing and aluminum foil sheet.

- <p>Aluminum foil facing is a thin layer of aluminum laminated to a substrate, typically used in construction for insulation and moisture barrier purposes. It provides a reflective surface that can enhance energy efficiency by reflecting heat. On the other hand, aluminum foil sheet is a flat, flexible material made of pure aluminum or aluminum alloy, commonly used in cooking, food packaging, and crafts. It is not bonded to any other material and is available in various thicknesses and widths. The primary difference lies in their applications and composition; foil facing is part of a composite material for construction, while foil sheets are standalone materials for a variety of uses.</p>

- Q: Is it safe and effective to use aluminum foil as a facing material for making soup?

- <p>Using aluminum foil directly to make soup is not recommended. Aluminum foil is not designed for cooking food as it can react with acidic or alkaline ingredients, potentially releasing harmful substances into the food. It is also not heat resistant and can melt or warp when exposed to high temperatures. For safe and effective soup making, use materials specifically designed for cooking, such as stainless steel, enameled cast iron, or non-stick pots. These materials are safe for cooking and can withstand high temperatures without compromising the quality or safety of your soup.</p>

- Q: Is it hazardous to cook acidic or salty foods with aluminum foil?

- <p>Using aluminum foil with highly acidic or salty foods is generally safe, but it's important to use the correct type of foil. Heavy-duty aluminum foil is designed for cooking and is safe for use with acidic and salty foods. However, avoid using aluminum foil with reactive metals, as it can cause a chemical reaction. Always follow cooking instructions and be cautious with prolonged cooking times or high temperatures, as these can potentially cause the foil to break down and release small amounts of aluminum into the food. For best results, opt for non-reactive cookware or use parchment paper or silicone baking mats as alternatives.</p>

- Q: Is it safe to use aluminum foil with a reflective side for storing food?

- <p>Yes, aluminum foil facing can be used for food storage. It is commonly used to wrap, cover, or store food in the refrigerator or freezer. The reflective side of aluminum foil is safe for food contact as it is made of a food-grade material. However, it's important to ensure the foil is clean and free from any damage or sharp edges that could puncture other food packaging. It's also advisable to avoid using it in direct contact with acidic or alkaline foods, as this can cause the foil to corrode and potentially release aluminum into the food.</p>

- Q: This question asks for methods to store aluminum foil to prevent damage and rusting.

- <p>Aluminum foil is resistant to rusting, but it can still be damaged if not stored properly. To store aluminum foil, keep it in a cool, dry place away from direct sunlight. Use an airtight container or a resealable plastic bag to protect it from moisture and air, which can cause it to oxidize and lose its shine. Avoid stacking heavy items on top of it, as this can cause dents and tears. If you have a large amount, consider using a foil storage box with compartments to keep it organized and protected.</p>

- Q: Is it possible to use aluminum foil facing as a substitute for a roasting pan?

- <p>While aluminum foil facing can be used in some baking situations, it is not recommended to use it as a direct substitute for a roasting pan. Aluminum foil is not designed to withstand the high temperatures of a roasting process and can melt or warp, leading to uneven cooking and potential safety hazards. A proper roasting pan is made to handle high heat and distribute it evenly, ensuring that your food cooks properly. For best results and safety, use a designated roasting pan or a baking sheet with a higher heat tolerance.</p>

- Q: This question asks for a comparison of the benefits and drawbacks associated with the use of aluminum foil facing in various applications.

- <p>Aluminum foil facing offers several advantages, including excellent heat reflection, which can improve insulation and energy efficiency in buildings. It also provides a moisture barrier, which can protect against water damage and mold growth. Additionally, aluminum foil facing is lightweight, easy to install, and resistant to corrosion. However, there are disadvantages such as its limited strength and durability compared to other materials, making it prone to punctures and tears. It can also be less aesthetically pleasing and may require additional protective layers for long-term use. Furthermore, improper disposal can contribute to environmental concerns due to its non-biodegradable nature.</p>

- Q: This question asks for instructions on how to store food wrap materials after they have been used.

- <p>After using food wrap materials, it's important to clean them properly before storing. Rinse off any food residue with warm water and mild dish soap. Avoid using abrasive materials that could damage the wrap. Once clean, gently pat dry with a clean towel or let air dry. Store the wraps in a cool, dry place away from direct sunlight to prevent degradation. You can use a clean, airtight container or resealable plastic bag to keep them protected and dust-free. Always check for any signs of wear or damage before reusing to ensure food safety.</p>

- Q: Is it possible to use aluminum foil with a reflective side to create a wrap for outdoor eating purposes?

- <p>Yes, you can use aluminum foil facing to make a wrap for eating outdoors. Aluminum foil is a versatile material that can be used to wrap food for various purposes, including outdoor dining. The reflective side can help keep the food warm or cool, depending on the situation. However, it's important to ensure that the foil does not come into direct contact with the food, especially if it's acidic or high in salt, as this can cause the foil to break down and potentially contaminate the food. Use the foil as a barrier or layer between the food and other surfaces to maintain hygiene and椋熷搧瀹夊叏.</p>

- Q: Is it possible to use aluminum foil with a shiny side facing up as a liner for a baking pan?

- <p>Yes, you can use aluminum foil facing as a baking pan liner. The shiny side of the aluminum foil is non-stick and can be used to line baking pans, making it easier to remove baked goods without sticking. Ensure the foil is heavy-duty to withstand high temperatures and prevent tearing. However, avoid using it for direct contact with acidic or alkaline foods, as the foil may react with them. Always follow the manufacturer's guidelines for safe use.</p>

Send your message to us

Aluminum Foil Facing Hexagonal Chicken Wire Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords