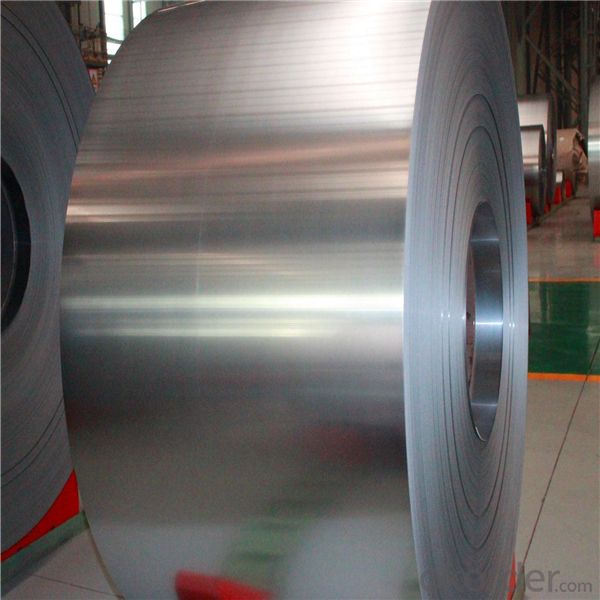

Hot Rolled Steel Sheets in Coil Chinese Supplier Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Standard: AISI, ASTM, BS, DIN, GB, JIS

Steel Grade: Q235BThickness: 1.2mm-20mm

Origin: China (Mainland)

Technique: Hot Rolled

Application: Making pipes, etc.

Brand Name: SS400B, Q195, Q235, SPHC, SPHT1

Width: 900mm-2000mm

Length: Coils

Packaging & Delivery

Packaging Detail: Standard package

Delivery Detail: Within 7-15days after we receive your deposit

| Standard | AISI, ASTM, BS, DIN, GB, JIS, |

| Grade | Q195/Q235/Q345/45# |

| Thickness | 2.50,2.70,2.75,2.8,2.9,2.95,3.0,3.25,3.3,3.5,3.75,3.8,3.9,3.95,4,4.25,4.5,4.7,4.75,5,5.5,5.75, 6,6.75,7,7.5,7.75,8,8.75,9,9.5,9.75,10,10.5,11,11.5,12 ,15.75 |

| Width | 685/735/1010/1250/1500/1800/2000mm |

| Coil Weight | 685/735 __6.5 T 1250 __16.5T 1500 __27.5T 1800/2000__32.5T |

| Application | construction, household appliance, Automobile, light industry, etc |

| Packaging | Standard package, suitable for transportation. |

| Delivery | Within 30 days after contract signed |

| Payment term | T/T or L/C |

Product Image:

FAQ

1. Q: What's the MOQ?

A: Our MOQ is 25mt.

2. Q: What's the delivery time?

A: It will take about 30 days after TT or L/C.

3. Q: What is the payment terms?

A: T/T, L/C at sight

4. Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

5. Q: What certificate do you have?

A: We have SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.

- Q: Steel sticks- it has meaning to us -similar to my deceased father's name, Steven fits our style as people. We like the hardness of it for our little man. We need a middle name though. Open to suggestions, thank you=)

- Steel Rod Tompkins Steel Blaze Tompkins Steel Adam Tompkins

- Q: I live in Dubai. I want to make a damascus steel sword and have no idea where to get the steel or what sort of steel I should get.First to adress the access of my steel...I need to get some low carbon and high carbon steel for the Damascus....what sort of steel is recommended for this? Also where would I be able to get my hands on it (Internet options e.g websites or locations)THANKS

- hI Jordan damascus steel is not actually a steel it is a composite material like the damascus rifle barrels the Afghan's use it is made from wire wrapped around an inner mandrel the beaten on an anvil till all the wire becomes one so it is several types of iron and steel beaten together and forged to produce it so it is not something you can actually buy as a material the tribesmen that produce these swords have these secret methods of doing this so there is the first problem. it is not like cast steel which is what most swords are made of it is far more complex in it's construction. so you may need to do a lot of research to find out how. what is a similar idea is the SAMURAI sword that is made up of combining different steels together and forged into a very sharp and capable killing blade.

- Q: How do steel coils contribute to structural integrity in buildings?

- The role of steel coils in ensuring the structural integrity of buildings cannot be overstated. They play a vital role in multiple ways. To begin with, steel coils are extensively utilized in the construction industry to manufacture essential building components like beams, columns, and trusses. These components are responsible for providing support and stability to the overall structure. Due to their exceptional tensile strength and durability, steel coils guarantee that these components can withstand heavy loads and maintain their structural integrity over an extended period. This is particularly crucial in buildings with multiple floors or large open spaces, where the structural elements need to bear substantial weight without deforming or collapsing. Moreover, steel coils are also instrumental in reinforcing concrete structures. Reinforced concrete is a widely adopted construction technique, and steel coils, in the form of reinforcement bars or mesh, are embedded within the concrete to counteract tensile forces. While concrete excels at withstanding compressive forces, it is weak in tension. By incorporating steel coils, the composite material gains the ability to resist both compression and tension, thereby enhancing its structural integrity. This reinforcement technique is particularly vital in high-rise buildings or structures subject to seismic activity, where the risk of structural failure due to bending or cracking is heightened. Another significant contribution of steel coils to structural integrity lies in their corrosion resistance properties. Steel coils are often coated with protective layers, such as zinc through galvanization or paint, to prevent corrosion caused by moisture, chemicals, or environmental factors. Corrosion weakens the structural integrity of steel, leading to degradation and potential failure. By utilizing corrosion-resistant steel coils, the lifespan of the building is prolonged, and the risk of structural damage is significantly diminished. Furthermore, steel coils offer tremendous versatility in design and construction. Their flexibility and malleability allow for the creation of complex and intricate building structures, enabling architects and engineers to push the boundaries of design while maintaining structural integrity. Steel coils can be shaped, bent, and welded into various forms, making them an ideal material for constructing innovative and aesthetically pleasing buildings. In conclusion, steel coils are indispensable in ensuring the structural integrity of buildings. Their strength, stability, durability, corrosion resistance, and design versatility make them an essential material in modern construction, guaranteeing the safety and longevity of buildings for years to come.

- Q: it isn't a SIGG water bottle or any other brand, as it's from thingsengraved what I'm wondering is, is this just as good as a SIGG water bottle, or is there any difference?

- Should be OK- that's reputable vendor. Suggest initial flush insides with very mild acid (fill ~20% with mild vinegar, Pepsi, etc., then shake 1 minute) then rinse 2 times, then look inside to confirm it looks clean.

- Q: Can steel coils be coated with color-changing materials?

- Yes, steel coils can be coated with color-changing materials. These materials are typically applied as a topcoat or overcoat on the steel surface, allowing the coils to exhibit different colors or hues based on external factors such as temperature, light, or chemical reactions. This coating technology can provide visual appeal, aesthetic versatility, and even functional benefits to steel coils in various applications.

- Q: What is the process of pickling and oiling steel coils?

- The process of pickling and oiling steel coils involves several steps to ensure the quality and protection of the steel. Firstly, pickling is the process of removing impurities and scale from the surface of the steel coil. This is typically done by immersing the coil in an acid bath, such as hydrochloric acid or sulfuric acid, which helps to dissolve any oxides, rust, or other contaminants present on the surface. This step is crucial as it prepares the steel for further processing and prevents any potential defects or corrosion. After pickling, the steel coils are rinsed with water to remove any residual acid and then dried. Once the coils are clean and dry, they are then coated with a layer of oil to provide temporary corrosion protection and lubrication during subsequent handling and transport. The oil coating helps to prevent the steel from rusting or oxidizing before it is further processed or used in various applications. The oiling process can be done in several ways. One common method is by applying the oil using a roller or brush, ensuring that the entire surface of the coil is evenly coated. Alternatively, the coils can be passed through a bath or spray chamber where the oil is applied. The type of oil used can vary depending on the specific requirements of the steel and its intended use. Some common oils include mineral oil, synthetic oils, or specialized rust-preventive coatings. Once the oiling process is complete, the steel coils are typically stacked, wrapped, or packaged for storage or transportation. It is important to handle the coils carefully to avoid damaging the oil coating and compromising the corrosion protection. Overall, pickling and oiling steel coils are essential steps in the steel manufacturing process to ensure the quality, cleanliness, and protection of the steel, ultimately extending its lifespan and enhancing its performance in various applications.

- Q: Got small (.177) bb gun for fun with my son...From the manual:'Steel shot will fire at a higher velocity then lead shot with with the same muzzle energy. As a result, more caution is required when using steel shot because of a greater hazard of ricochet. Lead, because of its lower velocity, usually has less penetrating power and is less likely to ricochet.'Are you agree with that? ;)

- steel is made of iron mainly (and carbon) its density is 7.86 g/cm? approximately. and lead has density=11.4 g/cm?. so, if have same volume and shape steel will have less mass and thus will have greater velocity for same muzzle energy. I agree the manual. for more information on ricochet

- Q: What are the key players in the steel coil manufacturing industry?

- The key players in the steel coil manufacturing industry are typically large multinational companies that have significant market share and influence. Some of the prominent players in the industry include: 1. ArcelorMittal: As the world's largest steel producer, ArcelorMittal is a major player in the steel coil manufacturing industry. They operate in more than 60 countries and have a diversified product portfolio. 2. Nippon Steel Corporation: Nippon Steel is a leading Japanese steelmaker and one of the largest steel coil manufacturers globally. They have a strong presence in automotive and construction sectors. 3. POSCO: Based in South Korea, POSCO is a major player in the steel industry, including steel coil manufacturing. They are known for their high-quality products and advanced technology. 4. Baosteel Group Corporation: Baosteel is the largest steelmaker in China and one of the largest globally. They have a wide range of steel products, including steel coils, and are known for their strong research and development capabilities. 5. Thyssenkrupp AG: Thyssenkrupp is a German multinational conglomerate with a significant presence in the steel coil manufacturing industry. They have a diverse product range and focus on innovation and sustainability. 6. United States Steel Corporation: As a leading American steel producer, United States Steel Corporation plays a crucial role in the steel coil manufacturing industry. They have a strong presence in the automotive, construction, and energy sectors. 7. JFE Holdings, Inc.: JFE Holdings is a Japanese steel conglomerate and one of the key players in the steel coil manufacturing industry. They have a wide range of steel products and are known for their quality and customer-oriented approach. These are just a few of the key players in the steel coil manufacturing industry, and there are many other companies that contribute to this sector. The industry is highly competitive, and these companies continuously strive to innovate, improve efficiency, and meet the ever-evolving demands of the market.

- Q: What are the different cutting methods for steel coils?

- There are several different cutting methods for steel coils, including shearing, slitting, and laser cutting. Shearing involves using a large blade to cut through the coil, typically resulting in a straight cut. Slitting involves passing the coil through circular blades that create narrower strips or sheets. Laser cutting uses a high-powered laser beam to melt or vaporize the steel, providing precise and intricate cuts. Each method has its advantages and is chosen based on the specific requirements of the project.

- Q: Steel, Sturm, and Kitiara are in a series called the Dragonlance Chronicles.

- Steel Brightblade

Send your message to us

Hot Rolled Steel Sheets in Coil Chinese Supplier Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords