Hot Rolled Steel Sheets from China Cheap Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

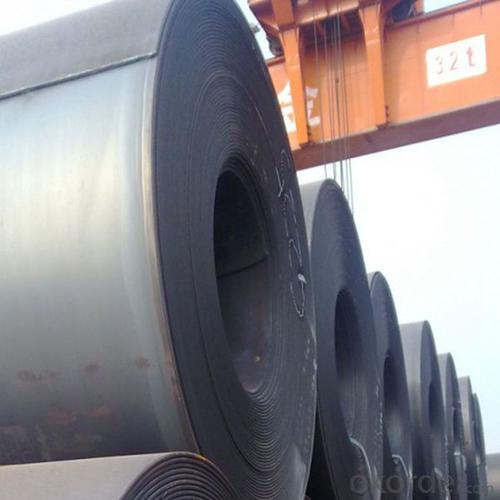

DESCRIPTION FOR CARBON STEEL PLATE

Production | hot rolled steel coils ss400 |

Port | Tianjin, China |

Category | Minerals & metallurgy |

Thickness | 1.8-16mm |

Width | 1000-1500mm |

Coil Weight | about 23 tons |

Material Grade | SS400\Q235\Q345B |

Technique | Hot Rolled |

Standard | GB ,JIS |

Test | With Hydraulic Testing, Eddy Current , Infrared Test |

Surface | 1) Bared 2) Black Painted (varnish coating) 3) Galvanized 4) Oiled |

Package | in bundles, strapped by strips. Or as customer’s requirement |

Sample | Common products, we can provide freely, for special production,we can depends on negotiation. |

MOQ | 50 tons |

Payment | 100% L/C at sight, 30% T/T in advance, and the balance against the copy of B/L or negotiation |

Delivery time | Within 10-25 days, according to quantity, asap save customer’s time |

Certificate | ISO |

TRADE TERMS :FOB, CFR, CIF

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

PICTURES:

FAQ

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q: Whats the difference in composition? When LTCS is used generally?Whats the temperature range, that these materials can be used? Is there any relation between Killed carbon steel, LTCS, stainless steel, carbon steel(normal)? How to categorise/classify these?Thankyou very much in advance..

- When exposed to elevated temperatures, quenched and tempered steels are more susceptible than normalized steels to permanent reduction in strength. This is especially true when exposure temperature begins to approach tempering temperature used when the parts were produced. In addition to losing strength, tempered steels also may experience reduced impact toughness after being exposed to long-term elevated temperatures. General belief is that this is the reason for LCC's reduced maximum allowable temperature limit of 345°C / 650°F in B16.34.

- Q: A friends of mine says he has balls of steel and i told him i would melt em off with lava. He said it wouldnt work. i disagree

- Standard steel melts around 1400-1500 C. Erupting lava can be as hot as 1600 C. There are various types of steel with different melting points though, and the temperature of lava varies widely, so your question can't really be answered definitively. Some lava is definitely hot enough to melt steel though, so you are right and your friend is wrong. :)

- Q: Does anyone know anything about Kodiak Steel Homes?

- Steel framing replaces all the wood making the house stronger and resistant to termites. Costs about $2,000 more per house and there is a lack of trained framers in most cities. Never heard of Kodiak brand. Do you know a city where they are located?

- Q: What are the challenges in coil slitting for thin gauge materials?

- Coil slitting for thin gauge materials comes with its own set of challenges that need to be addressed for a successful operation. One major challenge is the handling and stability of the thin gauge material. The thinner the material, the more prone it is to deformation, wrinkling, or even tearing during the slitting process. This requires careful attention to the handling equipment and techniques to ensure proper tension and support throughout the slitting operation. Another challenge is maintaining consistent and precise slitting widths. Thin gauge materials are often used in applications where accuracy is crucial, such as in electronic components or automotive parts. Any variation in slitting width can lead to functional defects or assembly problems. Achieving precise slitting widths in thin gauge materials requires high-quality slitting knives, well-maintained slitting machinery, and accurate tension control systems. Additionally, thin gauge materials are more susceptible to surface defects, such as scratches or burrs, during the slitting process. These defects can affect the material's appearance, performance, or even its safety. Proper selection of slitting knives and regular maintenance of the slitting machinery are essential to minimize the occurrence of surface defects. Furthermore, thin gauge materials often have a higher yield strength, meaning they are more resistant to deformation. This poses a challenge when it comes to achieving clean and straight edges during the slitting process. Special considerations need to be taken to ensure that the slitting knives are sharp and properly aligned to achieve clean cuts without introducing any edge defects. Lastly, thin gauge materials are generally more sensitive to external factors such as temperature, humidity, or static electricity. These factors can affect the material's dimensional stability, leading to variations in slitting width or other quality issues. Consequently, it is important to establish suitable environmental conditions and implement proper anti-static measures to minimize the impact of these factors. In summary, the challenges in coil slitting for thin gauge materials revolve around handling and stability, maintaining precise slitting widths, minimizing surface defects, achieving clean and straight edges, and mitigating the impact of external factors. Overcoming these challenges requires a combination of appropriate equipment, techniques, and operational controls to ensure high-quality slitting results.

- Q: ok I got a dpms ar 15 and all i have put though it is good brass 223 ammo but is it ok to shoot the old crappy steel cased wolf ammo out of it will it hurt its function or will it hurt it cosmetically?

- Overall it's dirtier. In this age however it's also cheaper. So if you need to stock up. In case. It's still a good option. Fire your brass first.

- Q: Steel Strings on your guitar or nylons? Why?

- There is no OR about it. You CANNOT use steel strings on a nylon string guitar because the increased tension will actually warp the top of the guitar and eventually pull the bridge right off! (I have seen it happen several times!) Although it is possible to put nylon strings on a steel string guitar it is not recommended. Nylon strings do not have as much tension as a steel string guitar is designed for. Steel string guitar necks are actually designed with a bit of back bow to compensate for the high tension of steel strings. Nylon strings have a much lower tension which could cause the neck of a steel string to settle slightly, which could actually cause the strings to fret out. It is not common, but it does happen. So keep your guitars happy and only string them with the proper strings.

- Q: How do steel coils contribute to the agricultural machinery industry?

- Due to their versatile and durable nature, steel coils play an essential role in the agricultural machinery industry. They are used in various applications and contribute significantly to improving the efficiency and productivity of agricultural machinery. Manufacturing equipment frames and structures is one primary way steel coils contribute to the agricultural machinery industry. These frames provide the necessary strength and stability to withstand the demanding conditions of agricultural operations. Whether it's tractors, harvesters, or tillers, steel coils are utilized to create robust and rigid frames capable of handling heavy loads, vibrations, and impacts. Moreover, steel coils are vital in fabricating components like plow blades, cultivator tines, and seed drills. These components are crucial for soil preparation, seed planting, and crop maintenance. Steel coils provide the necessary strength and resistance to wear and tear, ensuring these components can endure the rigors of agricultural operations and have a prolonged lifespan. Additionally, steel coils are used in manufacturing hydraulic systems and other moving parts in agricultural machinery. These systems are responsible for powering and controlling various functions such as lifting, lowering, and steering. Steel coils provide the necessary strength and flexibility for these systems to function optimally, ensuring smooth and efficient operation of agricultural machinery. Furthermore, the use of steel coils in the construction of agricultural machinery enhances equipment safety and longevity. Steel is renowned for its excellent resistance to corrosion, rust, and extreme weather conditions. By incorporating steel coils in the manufacturing process, equipment remains durable and reliable even in harsh environments, ultimately reducing maintenance costs and improving the overall lifespan of the machinery. In conclusion, the agricultural machinery industry heavily relies on steel coils. Their versatility, strength, and durability are indispensable for manufacturing equipment frames, components, hydraulic systems, and other moving parts. By utilizing steel coils, the agricultural machinery industry can produce robust and efficient equipment capable of withstanding demanding agricultural operations, improving productivity, enhancing safety, and extending the lifespan of the machinery.

- Q: What are the dimensions of steel coils used in the mining equipment industry?

- The dimensions of steel coils used in the mining equipment industry can vary depending on the specific application and equipment. However, common dimensions for steel coils in this industry range from 0.5 to 3 millimeters in thickness and 600 to 2000 millimeters in width. The length can also vary but is typically around 1000 to 3000 meters.

- Q: If i get a samurai sword made of carbon steel, what is the hardest thing i can hit before it breaks? Or will it not break?

- Real katanas need regular maintenance, they rust easily and dull quickly. If you get a replica chances are it will break the first time you hit anything with it. If you can find one, the WW2 officers swords were of good quality and the modern metals mean it doesn't rust or dull as easily. If you do insist on getting a carbon steal blade be ready to oil it often. It will rust at the mention of moisture.

- Q: What are the key properties of steel coils?

- Some key properties of steel coils include high strength, durability, and flexibility. They have excellent resistance to corrosion, making them suitable for various applications in construction, automotive, and manufacturing industries. Steel coils also offer good formability and can be easily shaped into different sizes and dimensions. Additionally, they have high thermal conductivity, allowing for efficient heat transfer in certain applications.

Send your message to us

Hot Rolled Steel Sheets from China Cheap Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords