Hot Rolled Steel With High Quality and Good Price Sheets From China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION FOR SS400 CARBON STEEL SHEET

1.Thickness: 1-200mm

2.Width: 100-3000mm

3.Length: 1000-12000mm

4. Applications :mining machinery, environmental protection, engineering

5. Grade:SS400 A 36 Q195.Q235.Q345.SPCC.SPCH

6.Surface : Hot Rolled Cold Rolled Galvanized Steel

DESCRIPTION FOR CARBON STEEL PLATE

Product | carbon steel plate price per ton |

Place of origin | Tianjin,China mainland |

MOQ | 25 tons |

Thickness | 1mm-200mm |

Width | 1000mm-3000mm |

Length | 1000mm-2000mm |

Application | widely |

Standard | AISI,ASTM,BS,DIN,JIS,GB,etc |

Grade | A572,A573,A633,A678,A709,A710,G3101,G3136,etc |

Tpye | Steel plate |

Surfacing | Coated |

Productive Technology | Hot Rolled & Cold Rolled |

Price | FOB USD 500-900 per ton |

Port | TIANJIN,SHANGHAI |

Payment Terms | L/C,T/T,Western Union,MoneyGram |

Product Ability | 1000 tons per month |

Delivery | 10 days after deposit or according to customers' quantity |

Packing | standard seaworthy export packing or as the request of customers |

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

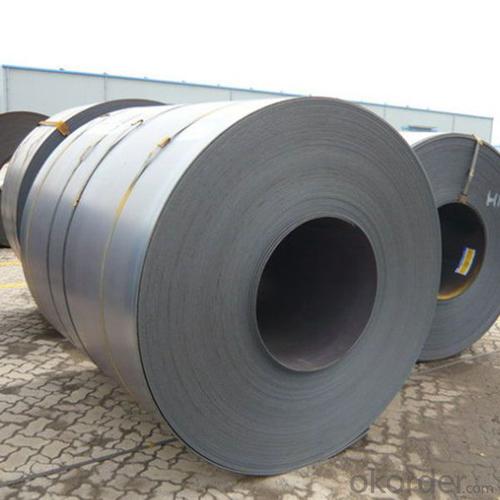

DETAILED PICTURES FOR STEEL COILS

EXPORT MARKET FOR STEEL COILS/SHEETS

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

OUR SERVICE

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ:

Q:Do you have OEM service?

A: Yes.Variety of products size,quality and quantity can be customized according to your need.

Q:Could you support free sample?

A:Yes.We can supply FREE samples.But the delivery charges will be covered by our customers.

Q:How about the delivery time?

A:Within 15-30days after receiving the deposit or L/C at sight.

FAQ:

Q:You are Factory or Trading Company?

A:We are factory,our main products include Steel plate,Steel Bar,Steel coils.

Q:What’s the MOQ?

A:Generally,the trail order will be accepted.The MOQ can be confirmed according to the different products.For example,the MOQ of rebar will be 25-50MT,the galvanized steel pipe will be 10MT,the stainless steel pipe will 1-5MT.

- Q: Hello,I have been thinking about buying a Tungsten Carbide Diamond wedding band for my husband but one of my family members keep telling me that Tungsten Carbide is merely steel and hence, a low quality metal, therefore, I shouldn't buy it. I don't really know much about it. Please if anyone can tell me more about this metal? Thanks.

- Edmond, a laser doesn't scratch anything, it melts. We're talking physical properties, not plasma properties. At NORMAL temperatures of 70-90 degrees F. If you don't understand the question, quit answering. Id imagine tungsten carbide can scratch itself. Much like an ape. :) - The Gremlin Guy -

- Q: How do steel coils contribute to the marine equipment industry?

- Steel coils play a crucial role in the marine equipment industry by providing the necessary raw material for the construction of various marine equipment and structures. These coils, which are typically made of high-strength steel, offer several key contributions to the industry. Firstly, steel coils are used in the manufacturing of ships and boats. The high strength and durability of steel make it an ideal material for constructing the hulls, decks, and other structural components of vessels. Steel coils are employed to fabricate these parts, ensuring the necessary strength and integrity to withstand the harsh marine environment, including corrosion, waves, and impact. Furthermore, steel coils are essential in the production of offshore structures such as oil rigs, drilling platforms, and wind turbines. These structures require robust materials capable of withstanding extreme weather conditions, heavy loads, and corrosive saltwater. Steel coils provide the necessary strength and corrosion resistance needed for these applications, ensuring the safety and longevity of offshore installations. Steel coils also contribute to the marine equipment industry by being utilized in the construction of various marine components and equipment. For instance, steel coils are used in the fabrication of propellers, shafts, and other propulsion systems. The high strength-to-weight ratio of steel makes it an excellent choice for these critical components, ensuring efficient propulsion and maneuverability of ships and boats. Moreover, steel coils are employed in the manufacturing of marine equipment such as cranes, winches, and lifting systems. These equipment pieces require sturdy materials capable of withstanding heavy loads and continuous use. Steel coils provide the necessary strength and durability for these applications, ensuring safe and efficient operations in the marine industry. In summary, steel coils contribute significantly to the marine equipment industry by providing the necessary raw material for the construction of ships, offshore structures, marine components, and equipment. The high strength, durability, and corrosion resistance of steel make it an ideal choice for withstanding the harsh marine environment. Without steel coils, the marine industry would face challenges in building robust and reliable marine equipment and structures.

- Q: How are steel coils used in the manufacturing of automotive wheels?

- Steel coils are used in the manufacturing of automotive wheels by being processed and shaped into the necessary components such as rims and spokes. These coils are cut, formed, and welded to create the desired wheel design, ensuring durability and strength for safe and reliable use on vehicles.

- Q: What are the typical coil thickness options?

- The typical coil thickness options vary depending on the specific application and industry. However, common coil thickness options range from 0.005 inches to 0.250 inches (0.127mm to 6.35mm), with various intermediate thicknesses available.

- Q: I have hundreds of pounds of scrap steel... who purchases this steel and what is the price per pound etc. of this? Does someone pick it up or do I bring it somewhere?

- It okorder /

- Q: How are steel coils used in the manufacturing of metal furniture?

- Steel coils play a vital role in the production of metal furniture as they are an essential component. Typically made from high-quality steel, these coils add strength, durability, and stability to the furniture. To incorporate steel coils into the manufacturing process, the first step involves cutting them to the desired length and width. This precise task is accomplished using specialized machinery and tools to ensure accurate dimensions for the furniture components. Once the coils are cut, they undergo shaping and forming processes to create various furniture parts such as chair frames, table bases, or cabinet structures. These coils can be bent, welded, or manipulated to achieve the desired shapes and designs. After the shaping process, additional treatments are applied to the steel coils to enhance their aesthetic appeal and provide protection against corrosion. This includes sanding, polishing, and the application of protective coatings or finishes to create a smooth and visually appealing surface for the furniture. In addition to their structural support and visual appeal, steel coils greatly contribute to the overall functionality of metal furniture. They possess excellent load-bearing capacity, ensuring that the furniture can withstand weight and pressure without bending or breaking. Furthermore, steel coils make metal furniture highly resistant to wear and tear, making it suitable for both indoor and outdoor use. With the ability to endure harsh weather conditions, these coils are particularly ideal for patio furniture or outdoor seating arrangements. In conclusion, steel coils are indispensable in the manufacturing of metal furniture as they provide essential strength, durability, and aesthetic appeal. Their versatility and reliability have made them the preferred choice for furniture manufacturers worldwide.

- Q: please i need your help in answering this question manufacturing process of steel containers and 20 references

- There are many types of steel containers and many different mnfg processes. There are also thousands of different steel alloys. Steel is used for canned food, compressed air cyclinders, hydraulic pressure vessels, electrical boxes, and many other containers. Steel containers are made out of sheet metal by soldering, brazing, spot welding, seam welding, riveting, bolting, screwing, etc. Heavier wall containers are fabricated of plate steel. Some steel containers are made by deforming the steel by extruding, forging, spin forming, drawing, ironing, etc. Some steel containers are made by machining. You should be able to find plenty of references if you search for these terms. good luck

- Q: i need flint and steel. are there common household items i can get the flint and the steel from????

- no common flint and steel in the house === you need to buy a Boy Scout - flint and steel fire starter kit === or a BIC lighter ... the other thing is a small jar filled with water [[ capped and water level near the top.]] hold the water-jar over some

- Q: We have to do a project for school on steel mines and i need 4 PROPERTIES OF A STEEL MINE PLEASE HELP!!! URGENT!!!

- There's no such thing as a Steel mine - steel is made from various raw materials (and now recycled metals). These materials may be mined separately and then combined at a steel mill - but steel is made, not mined. Steel, depending on what final characteristics they're trying to develop (strength, hardness, finish , etc.) can be comprised of iron, carbon, manganese, phosphorus, sulfur, nickel, chromium, etc. in varying quantities.

- Q: i want to know what is light gauge steel and the diffrences between light gauge steel and steel for roof truss.

- as a welder i can answere this. wel i think i can after 2 years of classes. so...light guage steel usually referes to the THICKNESS of the metal. also known as SHEET METAL. the only diffrences between light guage and roof truss is that a truss will be thicker metal ex- an i-beam for a structure is usually 1/2inch or 3/8 for smaller buildings. also there is no such thing as light weight steel. steel is steel the only thing that determins its weight is its size/thickness aluminum is a whole nother ballgame. ever see a pound of aluminum vs. a pound of steel? aluminum can be 1/2 or less the weight of steel. but its tensile strength suffers EX. say steel will snap at 70,000 pounds, aluminum will snap at 40,000 pounds, if it even snaps that is! it just tends to bend like rubber. aluminum is handy for many things because it will not rust.

Send your message to us

Hot Rolled Steel With High Quality and Good Price Sheets From China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords