Hot Rolled Steel Coils, SPHC, FE400, ST37-2

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

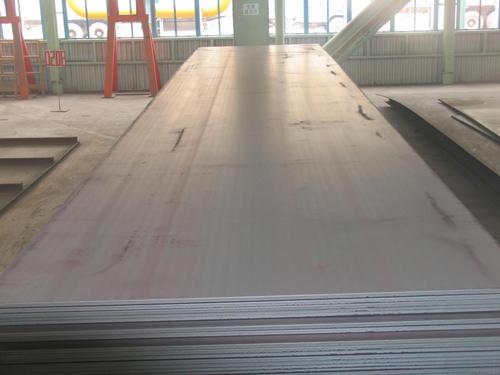

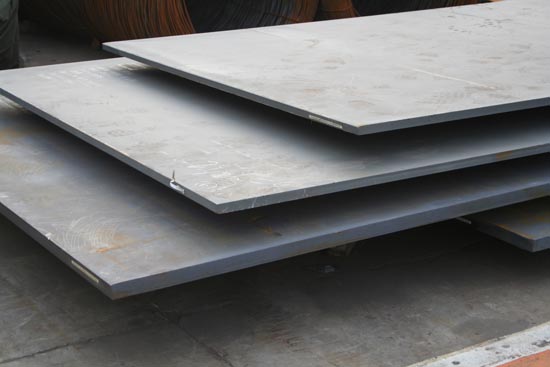

Hot Rolled Steel Coils/Sheets

Application:Floor board, factory stair boards, deck board, car boards ,staircases, lorry beds, elevator floors, general fabrication.

Material:Q195 Q225 Q235 Q345 A36 S235jr St37-2 SS400 and so on

Uses: fridge ,air conditioner, washing machine and household appliances, automobile,steel furniture, drum, motorcycles, fitting apparatuses, furniturem,builings electronic telecoms and gas- conveyance projects.

Product: | Hot Rolled Steel Coils/Sheets |

Material: | Q195,Q235,A36,SS400,S235JR,Q345,ST37-2, CCSB etc |

Standard : | JIS G3002 GB/T251B |

Technique: | hot rolled |

Thickness | 1.2mm to 200mm |

Tolerance of thickness: | :+/-0.03mm |

Width: | 750mm-2000mm |

Tolerance of width: | :+/-5.00mm (aiming to +/-2.00mm) |

Normal width: | 914mm, 1000mm, 1200mm, 1219mm, 1250mm,1500mm |

Length: | According to requirement |

Coil ID: | 508mm-610mm |

Coil Weight: | 10-25 Metric Tons |

Surface: | Black, Chromate, fingerprint resistant treatment, slight oiled or non-oiled, dry |

Port of Loading: | Tianjin/Shanghai port |

Packaging Details: | Standard export packing or according to the clients required |

- Q: What are the different coil cutting methods used for steel coils?

- There are several different coil cutting methods used for steel coils, including slitting, shearing, and laser cutting. Slitting involves using circular blades to cut the coil into narrower strips. Shearing involves using straight blades to cut the coil into desired lengths or shapes. Laser cutting, on the other hand, uses a high-powered laser beam to precisely cut the steel coil into specific shapes or patterns. Each method offers its own advantages and is chosen based on the desired outcome and requirements of the steel coil cutting process.

- Q: How are steel coils used in the manufacturing of storage systems?

- Steel coils are an essential component in the manufacturing of storage systems due to their durability, strength, and versatility. These coils are typically made from high-quality steel and are created by rolling the steel into a coil shape. In the manufacturing process of storage systems, steel coils serve various purposes. One of the primary uses of these coils is for the construction of shelves, racks, and frames. These components provide the structural support necessary to hold and organize items within the storage system. The strength of the steel coils ensures that the storage system can withstand heavy loads and remain stable over time. Additionally, steel coils are also used in the production of storage system accessories such as brackets, hooks, and dividers. These accessories provide additional functionality and customization options for the storage system, allowing users to optimize their storage space based on their specific needs. Moreover, steel coils are often used as the material for doors and panels in storage systems. The coils are molded and shaped to create sturdy and secure doors that provide easy access to the stored items while maintaining the overall integrity of the system. These doors can be designed with various locking mechanisms to enhance security and prevent unauthorized access. Furthermore, steel coils are crucial in the manufacturing of mobile storage systems. These systems, such as mobile shelving units or compactors, are designed to maximize storage capacity in limited space. The flexibility and versatility of steel coils allow for the creation of movable components that can be easily adjusted and reconfigured to accommodate changing storage requirements. Overall, steel coils play a vital role in the manufacturing of storage systems by providing the necessary strength, durability, and versatility required for these structures. Whether it is for shelves, accessories, doors, or mobile systems, steel coils ensure that storage systems are reliable, secure, and efficient in organizing and storing various items.

- Q: How are steel coils used in the manufacturing of structural components?

- Steel coils are used in the manufacturing of structural components by being processed through various techniques such as cutting, bending, and welding to form the desired shapes and sizes. These coils serve as the raw material for fabricating beams, columns, and other structural elements used in buildings, bridges, and infrastructure projects. The high strength and durability of steel make it an ideal choice for constructing load-bearing components, ensuring the stability and integrity of the structures.

- Q: What are the different types of steel surface treatments for coils?

- There are several types of steel surface treatments for coils, including hot-dip galvanizing, electro-galvanizing, galvannealing, and organic coating. Hot-dip galvanizing involves immersing the steel coil in a bath of molten zinc to create a protective layer. Electro-galvanizing applies a thin layer of zinc to the surface using an electrical current. Galvannealing is a process that combines galvanizing and annealing to create a zinc-iron alloy layer. Organic coating involves applying a protective layer of paint or other organic material to the steel surface.

- Q: Can anyone please tell me what is the DUCTILE TO BRITTLE TRANSITION TEMPERATURE IN STEEL LOW CARBON?Thanks.

- Transition Temperature Of Steel

- Q: I need to penetrate steel on my car but don't know which bit to use. Are there special bits for steel?

- Yes, they'll be marked HSS, High Speed Steel.

- Q: Can steel coils be used in the production of consumer goods?

- Consumer goods can indeed be produced using steel coils. In multiple industries, including automotive, construction, and manufacturing, steel coils are commonly employed as raw materials. Within the consumer goods sector specifically, steel coils can be utilized to manufacture a diverse array of items, spanning from appliances, furniture, and tools to packaging materials and even consumer electronics. The innate strength, durability, and adaptability of steel render it an optimal choice for fabricating consumer goods that necessitate stability, safety, and longevity. Furthermore, steel coils can be easily manipulated, molded, and shaped into distinct components or parts, enabling customization and design flexibility throughout the production process. Consequently, steel coils play an indispensable role in consumer goods production and find widespread use across various industries.

- Q: What are the different types of steel coil packaging materials?

- There are several types of steel coil packaging materials, including steel strapping, plastic strapping, stretch film, edge protectors, corner protectors, and cardboard tubes.

- Q: How are steel coils protected from humidity?

- Steel coils are typically protected from humidity through a process called galvanization, where a layer of zinc or another protective coating is applied to the surface of the steel. This coating acts as a barrier, preventing moisture from coming into direct contact with the steel and minimizing the risk of corrosion. Additionally, steel coils are often stored in dry, enclosed spaces or wrapped with moisture-resistant materials such as plastic or wax paper to further protect them from humidity.

- Q: What are the trends and developments in the steel coil industry?

- Over the past few years, the steel coil industry has undergone various trends and developments. These changes have been influenced by different factors, including advancements in technology, shifts in supply and demand, and concerns for the environment. One notable trend in the steel coil industry is the increasing utilization of advanced technologies in production. Automation and robotics have revolutionized the manufacturing process of steel coils, resulting in improved efficiency and quality control. These technologies have also enabled the industry to meet the rising demand for customized steel coils by allowing faster and more precise production. Another trend in the industry is the move towards lightweight and high-strength steel coils. With the increasing need for fuel-efficient vehicles, manufacturers are seeking lighter materials that still possess strength and durability. Steel coil producers are developing innovative products, such as advanced high-strength steels and ultra-high-strength steels, that meet these requirements. These materials offer enhanced performance while reducing the weight of the final product. Concerns for the environment have also spurred developments in the steel coil industry. There is a growing demand for sustainable and eco-friendly steel coils, leading to the adoption of greener manufacturing processes. Steel coil manufacturers are increasingly incorporating recycled materials and implementing energy-efficient technologies to reduce carbon emissions and waste generation. Additionally, there is a focus on improving the recyclability of steel coils to minimize their environmental impact throughout their lifecycle. Furthermore, the steel coil industry is experiencing a shift in the dynamics of supply and demand. Emerging economies, particularly in Asia, are driving the demand for steel coils due to rapid industrialization and urbanization. As a result, there have been increased investments in production capacity in these regions. Conversely, developed economies are witnessing a trend towards consolidation and specialization, with some companies focusing on niche markets or specific applications for steel coils. Overall, the steel coil industry is undergoing significant transformations that are being driven by advancements in technology, changing demand patterns, and environmental concerns. These trends and developments are reshaping the industry, making it more efficient, sustainable, and adaptable to the evolving needs of the market.

Send your message to us

Hot Rolled Steel Coils, SPHC, FE400, ST37-2

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords