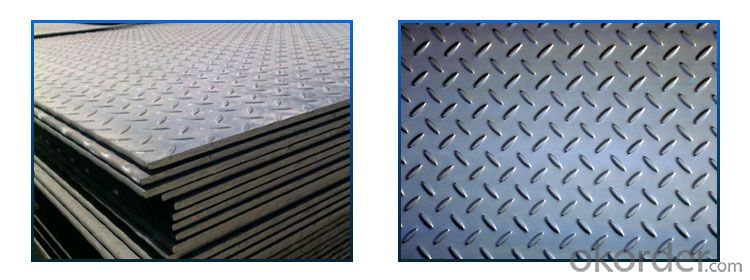

Prime Hot Rolled HR Steel Chequered Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Commodity | Checkered plate/sheet |

Thickness | 1.8mm-15mm as customer's requirement |

Width | 1000mm,1220mm,1250mm,1500mm |

Length | 2440mm,6m,8-12m, as customer’s requirement |

Standard & steel grade | ASTM A36 EN10025 S235JR;S355JR JIS G 3101 SS400;SS490;SS540 DIN 17100 ST 37-2 GB/T 700 Q235; Q345 |

Surface | Smooth, straight |

Packing | diamond (teardrop type), lentils form, round beans form |

Application | Be strapped with Iron packing belts, Standard exporting packing |

Standard | Grade | Chemical Compostiton(%) | |||||

C | Mn | Si | S | P | |||

≤ | |||||||

Q235 | A | 0.14~0.22 | 0.30~0.65 | 0.05 | 0.045 | ||

B | 0.12~0.20 | 0.30~0.70 | 0.3 | 0.045 | |||

C | ≤0.18 | 0.35~0.80 | 0.04 | 0.04 | |||

D | ≤0.17 | 0.035 | 0.035 | ||||

Mechanical Properties | |||||||

Standard | Tensile Strength(MPa) | Yield Point | Elongation(%) | ||||

Q235 | 375~500 | 235 | 26 | ||||

Q345B Chemical Composition(%) | ||||

C | Mn | Si | S | P |

≤0.20 | ≤1.70 | ≤0.50 | ≤0.035 | ≤0.035 |

Q345B Mechanical Properties | ||||

Tension Strength | Yield Point | Elongation | ||

470-630 | 345 | 21 | ||

Checkered steel plate beautiful shape, can prevent slippery, improved performance, save a lot of advantages, such as steel in transportation, construction, decoration, equipment around the base plate, machinery, shipbuilding and other fields have a wide range of applications.

- Q: hello friends, I have some old 7.62x54r on stripper clips its nasty gunk on it can i use steel wool to glean it and still have it fire safely?

- Jonathan, You won't have any problems firing the brass after you clean it with a solvent(such as brake clean) and steel wool. Keep in mind though, that brass is a soft metal. Use a less abrasive steel wool, such as 0000 to ensure you don't take too much brass off. Also, if you want your brass to be shiny, 0000 will ensure you won't have deep scratches in the brass. On a different note, there is a product called 'Flitz' that works great for polishing and cleaning up metals such as brass. It uses small abrasive particles in a liquid to polish and restore a bright finish. The ideal solution would be to run the brass through a tumbler or sonic cleaner. However, if you've only got a few cases and don't plan on using it that often they can be a bit pricy. Regards, Dustin All of the previous also applies to steel cases(just noticed they were steel), just add a good rust preventative and ensure the cases don't show any current signs of rusting as cleaning them up will most likely clean off any prior rust inhibitors. A rusted case is NOT safe to shoot.

- Q: My daughter wants a pair of steel toe cap boots for around the horses but wants them warm, so ideally fur lined etc. Does anybody know where I could purchase them as everywhere I look its only one or the other, cant get steel with fur lining. Very frustrating. I live in the uk. Many thanks.

- Steel toe boots around horses is a big no-no! horses are heavy enough to bend the steel and that could possibly cut into her foot. Even if it doesn't cut into her foot, the boot is ruined after the first time a horse does step on it. On the other hand, Mountain Horse and Ariat both make great winter riding boots.

- Q: How are steel coils used in the manufacturing of engine components?

- Steel coils are used in the manufacturing of engine components as they provide strength and durability. They are typically processed and shaped into various parts such as connecting rods, crankshafts, and camshafts, which are essential for the engine's functionality. The coils are formed, machined, and heat-treated to meet the precise specifications required for each component, ensuring optimal performance and reliability in engines.

- Q: What are the different methods of coil welding for steel coils?

- There are several different methods of coil welding for steel coils, each with its own advantages and disadvantages. Here are some of the most commonly used methods: 1. Resistance Welding: This method involves passing an electric current through the coils to generate heat, which then fuses the two ends together. Resistance welding is a fast and efficient process that produces strong and reliable welds. It is commonly used in industries where high-speed production is required. 2. Arc Welding: Arc welding uses an electric arc between an electrode and the workpiece to create a weld. This method can be further divided into different processes, such as shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). Arc welding provides good penetration and can be used on a wide range of steel coils. 3. Laser Welding: Laser welding utilizes a high-powered laser beam to melt and fuse the two ends of the coils together. This method offers precise control, high welding speeds, and minimal distortion. It is often used in applications where precision and aesthetics are crucial, such as the automotive and electronics industries. 4. Induction Welding: Induction welding involves heating the coils using electromagnetic induction. The heat generated melts the edges, which are then pressed together to form a weld. This method is particularly suitable for thin-gauge steel coils and provides good control over the welding process. 5. High-Frequency Welding: High-frequency welding utilizes high-frequency current to heat and weld the coils together. This method is commonly used for pipes and tubes and offers high production rates and good weld quality. 6. Friction Welding: Friction welding uses the heat generated by rubbing the two ends of the coils together to create a weld. This method is fast, reliable, and produces strong joints. It is often used in applications where high-strength welds are required, such as the automotive and aerospace industries. These are just a few of the different methods of coil welding for steel coils. The choice of method depends on factors such as the type and thickness of the steel, the required weld strength, production speed, and overall project requirements.

- Q: I'm a Hobbyist and want to Build my own axial-flow jet engine,can I use steel as the Turbine blades instead of Titanium which I can't get easily?? What about the other parts I can use for...?!

- Yes you can use steel but you will want to use super alloys like hastaloy and inconel. These withstand the heat in the combustion areas. These are the actual materials used in these stages. If you only want your engine to have a service life of a few hours a conventional hot work steel like H-13 will probably be OK Blades are investment cast in foundries that carefully control the rate of cooling to create a very uniform grain structure

- Q: how many persent of manganese in all types of carbon steel

- Not more than 1.65 % of manganese in carbon steel. *Carbon steel, also called plain carbon steel, is steel where the main alloying constituent is carbon. The American Iron and Steel Institute (AISI) defines carbon steel as: Steel is considered to be carbon steel when no minimum content is specified or required for chromium, cobalt, columbium, molybdenum, nickel, titanium, tungsten, vanadium or zirconium, or any other element to be added to obtain a desired alloying effect; when the specified minimum for copper does not exceed 0.40 percent; or when the maximum content specified for any of the following elements does not exceed the percentages noted: manganese 1.65, silicon 0.60, copper 0.60 *AISI 1040 is a carbon steel which is having a 0.60-0.90 % of manganese.

- Q: How does the surface finish of steel coils affect their performance?

- The surface finish of steel coils greatly affects their performance. A smooth and uniform surface finish enhances the coil's corrosion resistance, durability, and ability to resist wear and tear. It also improves the coil's ability to form and join with other materials, making it easier to work with during manufacturing processes. On the other hand, a rough or uneven surface finish can lead to decreased performance, as it can negatively impact the coil's ability to resist corrosion, reduce its overall strength, and potentially cause issues during processing and handling. Therefore, ensuring a proper surface finish is crucial in optimizing the performance and lifespan of steel coils.

- Q: I know you can still but steel core ammo. I have read that it IS Armor Piercing (AP) and I have read it is not. Which is true? I am not looking for its AP capabilities. I want it if it is or is not AP. I live in Oklahoma. I need to know if it legal for me to purchase it in this state; and where can i get it? I am over 18, not a felon, etc. I have seen it sold online in Oklahoma years ago, but have read it is and isn't legal to purchase here. I am looking for 7.62x39 steel core for an SKS. If anyone knows where or how to get some, please let me know, if it's legal. Thanks.

- You can legally buy chinese steel core and 855 5.56 which is also steel core. That's on the federal level. I don't know about your state in particular but ammo peircing ammo is illegal but there are different grades of steel. If that were the case I couldn't buy Bugarian steel cased light ball in 7.62x54R.

- Q: What are the challenges in storing and handling steel coils?

- Storing and handling steel coils presents numerous obstacles due to their size, weight, and potential risks associated with transportation and storage. The following are some of the challenges: 1. Space requirements: Steel coils are typically large and bulky, necessitating ample storage space. Finding suitable storage facilities that can accommodate the size and weight of the coils can be difficult, particularly in urban areas with limited space. 2. Weight and handling: Steel coils can weigh several tons, making safe handling a challenge. Specialized equipment, such as cranes or forklifts with sufficient lifting capacity, is necessary to move and position the coils without causing damage or injury. 3. Stackability: Storing steel coils in a secure and efficient manner requires careful consideration of their stackability. Coils must be stacked in a way that prevents deformation or damage to the lower coils, ensuring stability and minimizing the risk of toppling. 4. Corrosion prevention: Steel coils are susceptible to corrosion, especially when exposed to moisture or harsh environmental conditions. Implementing proper corrosion prevention measures, such as protective coatings or climate-controlled storage, is essential to maintain the quality and integrity of the coils. 5. Safety risks: Handling steel coils can be hazardous, as they can unexpectedly shift during transportation or storage. This poses a risk to workers involved in the handling process. Adequate training, appropriate personal protective equipment (PPE), and strict safety protocols are vital to minimize the potential for accidents or injuries. 6. Transportation challenges: Transporting steel coils from manufacturing facilities to storage facilities or end-users can be logistically complex. Coordinating the loading, securing, and unloading of the coils onto trucks or shipping containers requires careful planning and adherence to safety regulations. 7. Quality control: Steel coils must be stored and handled in a manner that maintains their quality. Mishandling or improper storage conditions can result in deformations, scratches, or other defects that can impact the performance and value of the steel. In conclusion, the challenges encountered in the storage and handling of steel coils necessitate attention to detail, appropriate equipment, and adherence to safety protocols to ensure the integrity of the product, the safety of workers, and the efficiency of operations.

- Q: Moravia’s coal and steel industries face challenges because they _____. a.do not run efficientlyb.have run out of resourcesc.have a declining work forced.have not privatized

- As someone who have lived in northern Moravia at industrial steel and coal city of Ostrava, the closest point is b), but it is questionable. I am not sure how to compare efficiency of largest steel mill in Czech Republic in comparison to China which is the biggest exporter, but Czech steel factories were modernized and run more efficient that 25-35 years ago, and been privatized and owned by Mittal. The workforce had been shrinking, so not exactly sure what that c is pointing to (aging of workforce, size of it, or quality). Northern Moravia is a part of larger coal basin that extend to Poland with large coal deposits. This was foundation for the steel industry in the 1800's together with large ore deposits that was mined in proximity of the Beskidy mountains less than 25 miles from Ostrava. The iron ore mines had been depleted for several decades, and since the late 70's when communists run the country, they were already importing Soviet iron ore. Coal mining within city of Ostrava cased to exist in the 1990's due environmental issues, and also cost. The mines were getting deeper and more costly to operate and there is no more mining within Ostrava. Couple mines are still in operation in Karvina county which is next to Ostrava. Currently the coal deposits south of the city were not opened due environmental issue which would mean destruction of third largest mountain range in the country. Therefore, my conclusion is is b, as the ore and coal resources been shrinking. The biggest challenge not mentioned here is of course competition from Russia, Ukraine, and China, which can produce steel much cheaper.

Send your message to us

Prime Hot Rolled HR Steel Chequered Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords