Hot Rolled Steel Channel Bar Q235 SS400 Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Steel Channel Bar Q235 SS400 Made In China at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel Channel Bar Q235 SS400 Made In China are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Steel Channel Bar Q235 SS400 Made In China

are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1.Our company enjoys high reputation on manufacturing and supplying U channel steel. Among those steel products, the U channel steel as per japanese, chinese and european can be regarded as our primary products.

Under those standard, the material grade includes: GB Q235B,GB Q345B/JIS G3192, SS400/EN 10025,S235JR and so on.

Here,the U channel steel as per japanese standard is posted just as reference.

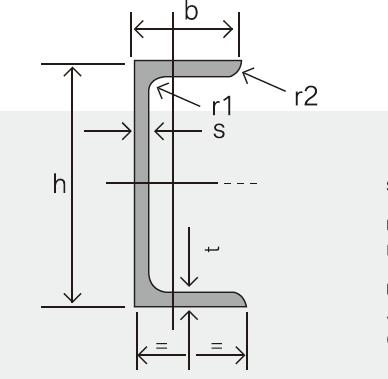

2. Dimension Figure:

Note:1.The height ranges from 50mm to 300mm

2.The breadth ranges from 25mm to 89mm

3.Theoretically speaking, the flange of U channel steel should bear stress, it’s to say that the U channel should be upright rather than lying under construction. Therefore, we strictly control the tolerance of the flange thickness.

3.The sections of U Channel Steel as per JIS Standard are shown in the below table:

JIS U CHANNEL | Standard h | Sectional b | Dimension s | t | Mass: Kg/m |

| (mm) | (mm) | (mm) | (mm) |

|

50x25 | 50 | 25 | 3.0 | 6.00 | 2.37 |

75X40 | 75 | 40 | 3.8 | 7.00 | 5.30 |

75X40 | 75 | 40 | 4.0 | 7.00 | 5.60 |

75X40 | 75 | 40 | 4.5 | 7.00 | 5.85 |

75X40 | 75 | 40 | 5.0 | 7.00 | 6.92 |

|

|

|

|

|

|

100X50 | 100 | 50 | 3.8 | 6.00 | 7.30 |

100X50 | 100 | 50 | 4.2 | 6.00 | 8.03 |

100X50 | 100 | 50 | 4.5 | 7.50 | 8.97 |

100X50 | 100 | 50 | 5.0 | 7.50 | 9.36 |

|

|

|

|

|

|

125X65 | 125 | 65 | 5.2 | 6.80 | 11.66 |

125X65 | 125 | 65 | 5.3 | 6.80 | 12.17 |

125X65 | 125 | 65 | 5.5 | 8.00 | 12.91 |

125X65 | 125 | 65 | 6.0 | 8.00 | 13.40 |

|

|

|

|

|

|

150x75 | 150 | 75 | 5.5 | 7.30 | 14.66 |

150x75 | 150 | 75 | 5.7 | 10.00 | 16.71 |

150x75 | 150 | 75 | 6.0 | 10.00 | 17.90 |

150x75 | 150 | 75 | 6.5 | 10.00 | 18.60 |

150x75 | 150 | 75 | 6.5 | 10.00 | 24.00 |

|

|

|

|

|

|

200X80 | 200 | 80 | 7.5 | 11.00 | 24.60 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: What are the factors that affect the price of steel channels?

- The price of steel channels can be influenced by various factors. Let's explore some of these factors: 1. Raw material costs play a significant role in determining the price of steel channels. The cost of materials like steel, iron ore, and coal directly affects the manufacturing cost of steel channels. Fluctuations in these raw material prices can, in turn, impact the final price of the channels. 2. Supply and demand dynamics also have an impact on steel channel prices. When demand for steel channels is high and the supply is limited, prices tend to rise. Conversely, if demand is low and there is excess supply, prices are likely to decrease. 3. Manufacturing and processing costs, including expenses related to labor, energy, and equipment, can influence the price of steel channels. Higher manufacturing costs may result in higher prices for the channels. 4. The level of competition among steel channel manufacturers can also affect prices. When multiple producers offer similar products, they may engage in price competition to attract customers, leading to lower prices. On the other hand, if there are fewer suppliers or if they offer unique products, prices may be higher. 5. Transportation and logistics costs can impact the final price of steel channels. Factors such as fuel prices, shipping distances, and transportation infrastructure all contribute to transportation costs, which can be passed on to the buyer. 6. Government regulations and tariffs are another factor that can influence steel channel prices. Trade policies, import duties, and government regulations can increase the price of imported steel channels, while subsidies or support from the government can lead to lower prices. 7. Economic conditions, both globally and domestically, have an impact on steel channel prices. Economic growth, inflation, and currency exchange rates can all influence the cost of steel channels. It is important to understand that these factors are interconnected and can vary depending on market dynamics and location. Therefore, buyers and sellers in the steel channel industry must consider these factors and their potential impact.

- Q: Can steel channels be customized to specific lengths?

- Yes, steel channels can be customized to specific lengths. Steel channels are typically available in standard sizes, but they can be cut or modified to meet specific length requirements. This customization process involves cutting the steel channel to the desired length and may also involve welding or other techniques to ensure the channel maintains its structural integrity. Customization of steel channels allows for greater flexibility in various construction and engineering applications.

- Q: What direction does channel steel use best?

- The ability of the channel to bear the vertical load is proportional to its vertical cross section, so the opening is left or right, and the maximum vertical load can be carried.

- Q: What is the square bevel washer used for channel steel?

- Two dimensional software Qinghua Qinghua Tianhe CAD is a coincidence. You can also check the size according to the national standard.

- Q: How do steel channels contribute to the overall sustainability of a structure?

- Steel channels contribute to the overall sustainability of a structure in several ways. Firstly, they are highly durable and have a long lifespan, reducing the need for frequent replacements and minimizing material waste. Secondly, steel channels are recyclable, allowing for their reuse in other construction projects and reducing the demand for new raw materials. Additionally, their lightweight nature makes transportation and installation more efficient, reducing energy consumption and carbon emissions. Lastly, steel channels offer design flexibility, allowing for efficient use of space and potential future adaptability, enhancing the overall sustainability of the structure.

- Q: Which is cheaper, the same size, ordinary channel steel and light channel steel? Price difference is not big?

- Light channel steel and ordinary channel compared to the same height, other sizes are thinner than ordinary channel, the natural weight is lighter.

- Q: Own attic, choose I-beam or channel?

- Oneself take attic, suggest to choose I-beam, and choose GB steel, because stainless steel in non GB is more.I-beam is a kind of economical section steel with better mechanical performanceFeatures: I-beamWide flange and large lateral rigidity. Good bending resistance.The two surfaces of the flanges are mutually parallel so that the connection, processing and installation are simple and convenient.Compared with the general steel, the utility model has the advantages of low cost, high precision, little residual stress, no expensive welding materials and welding seam detection, and the cost of steel structure production is saved by about 30%.Under the same section load, the weight of hot-rolled H steel structure is less than that of traditional structure 15%-20%.Compared with the concrete structure, the I-beam structure can increase the use area of 6%, while the weight of the structure can be reduced by 20% and 30%, and the internal force of the structural design can be reduced.The I-beam can be processed into T steel, and the castellated beams can form various section forms to meet the demands of engineering design and manufacture.

- Q: Can steel channels be used for conveyor systems?

- Yes, steel channels can be used for conveyor systems. Steel channels offer high strength and durability, making them suitable for supporting heavy loads and resisting wear and tear in conveyor applications.

- Q: What are the typical lengths of steel channels?

- The typical lengths of steel channels vary depending on the manufacturer and intended use. However, they are commonly available in standard lengths ranging from 20 feet (6.1 meters) to 40 feet (12.2 meters). These standard lengths are often used in construction projects and are suitable for various applications such as structural support, framing, and bracing. Additionally, manufacturers may offer custom cutting services to provide steel channels in specific lengths to meet the unique requirements of a particular project.

- Q: Can steel channels be used for shelving systems?

- Indeed, shelving systems can utilize steel channels. By virtue of their strength and durability, steel channels prove to be well-suited for bearing substantial loads. Their ability to be effortlessly affixed to walls or alternative structures yields a stable and robust shelving system. Moreover, the assortment of sizes and lengths in which steel channels are available permits customization to cater to distinct storage requirements. On the whole, owing to their vigor and adaptability, steel channels are widely favored for shelving systems in warehouses, garages, and various industrial environments.

Send your message to us

Hot Rolled Steel Channel Bar Q235 SS400 Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords