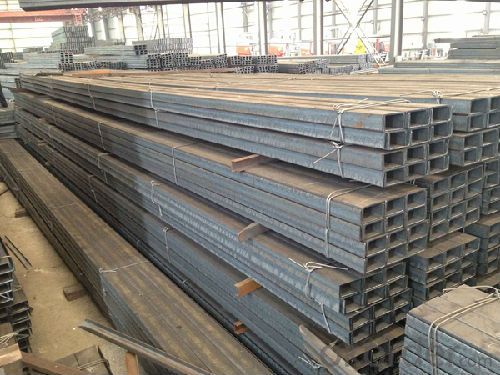

Q235 Hot Rolled Channel Steel With High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Q235 Hot Rolled Channel Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Q235 Hot Rolled Channel Steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Q235 Hot Rolled Channel Steel are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Description:

1. We are definitely specializing in manufacturing and supplying channel steel.

Standard: | GB |

Material/Grade: | Q235 |

Sizes: | 50mm to 280mm |

Sales Volume/Year: | 3000MT |

Destination Area: | Middle East, Africa, Southeast Asia |

2.Size, Length and Mass.

Size(mm) | Length(m) | Mass(Kg/m) |

180*68*7.0*10.5 mm | 6m, 12m | 20.174 kg/m |

180*70*9.0*10.5 mm | 6m, 12m | 23.000 kg/m |

Package & Delivery of Channel Steel:

The steel u channel will be packed in bundle with steel wire at each end of every bundle and color marking in order to help the customer to recognize his goods more easily at sight.

And steel u channel could be loaded into 20ft or 40ft container, or by bulk cargo. If the weight of each bundle reaches less than 3.5 mt, the loading by break bulk cargo should be choosed. When the weight of each bundle reaches less than 3mt, the loading by container should be choosed.

As for the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

All in all, we could do in accordance with customer's request.

Trade terms: FOB, CFR, CIF

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: What are the different methods of protecting steel channels from impact damage?

- There are several different methods of protecting steel channels from impact damage. One common method is to install protective guards or barriers around the steel channels. These guards can be made from materials such as rubber, foam, or plastic, and are designed to absorb and distribute the force of any impacts, preventing them from directly hitting the steel channels. These guards can be attached to the channels using adhesive, fasteners, or other mounting methods. Another method is to apply a protective coating or paint onto the steel channels. This coating can act as a barrier between the channel and any potential impact, reducing the risk of damage. The type of coating used will depend on the specific environment and level of impact resistance required. Using impact-resistant materials during the fabrication of the steel channels is also an effective method of protection. By using materials that have high impact resistance, such as hardened steel or composite materials, the channels are less likely to sustain damage in the event of an impact. In some cases, adding additional reinforcement to the steel channels can provide increased protection against impact damage. This can be achieved by attaching reinforcing plates or brackets to the channels, which can help distribute the force of an impact and prevent it from concentrating on a single point. Proper installation and maintenance of the steel channels can also play a crucial role in protecting them from impact damage. Ensuring that the channels are securely fastened and regularly inspected for any signs of wear or damage can help identify and address any potential issues before they become more serious. It is important to consider the specific requirements and environment in which the steel channels are being used when choosing a method of protection. Consulting with experts or professionals in the field of steel fabrication and impact protection can provide valuable insights and guidance in selecting the most suitable method for protecting the steel channels.

- Q: What are the different fabrication techniques for steel channels?

- There are several different fabrication techniques for steel channels, including hot rolling, cold rolling, and extrusion. Hot rolling involves heating the steel to high temperatures and then passing it through a series of rollers to shape it into the desired channel profile. Cold rolling, on the other hand, is performed at room temperature and involves passing the steel through rollers to achieve the desired shape. Extrusion is a process where the steel is forced through a die to create the channel shape. Each technique has its own advantages and is chosen based on factors such as the required dimensions, tolerances, and surface finish of the steel channel.

- Q: Channel structure, angle steel, I-beam and so on, if not painted, the impact on life?

- The influence will reduce the life span

- Q: What are the different types of connections for steel channels?

- There are several different types of connections that can be used for steel channels. The choice of connection type depends on the specific application, load requirements, and structural design considerations. One common type of connection for steel channels is the bolted connection. In this type of connection, steel channels are connected using bolts, typically with the help of nuts and washers. Bolted connections provide flexibility and ease of installation, allowing for adjustments and disassembly if necessary. They are commonly used in applications where a moderate level of load transfer is required. Another type of connection for steel channels is the welded connection. In this type of connection, the steel channels are joined together through the process of welding. Welded connections offer high strength and rigidity, making them suitable for applications where heavy loads and structural stability are critical. Welding provides a permanent and durable connection, eliminating the need for additional fasteners. In some cases, steel channels can also be connected using a combination of bolted and welded connections. This hybrid connection approach provides the advantages of both connection types, allowing for a robust and efficient solution that meets specific design requirements. Additionally, there are specialized connections available for specific applications. For example, slip-resistant connections are used in situations where the channels need to withstand dynamic or lateral loads. These connections typically incorporate additional features such as serrated surfaces or special fasteners to enhance grip and prevent slippage. It is important to note that the selection of the appropriate connection type for steel channels should be done in accordance with relevant building codes, engineering standards, and structural analysis. Consulting with a structural engineer or design professional is recommended to ensure the connections meet the necessary safety and performance requirements.

- Q: Are steel channels resistant to pests and insects?

- Yes, steel channels are highly resistant to pests and insects. Due to their strong and durable nature, steel channels do not provide a suitable environment for pests and insects to infest or damage.

- Q: Are steel channels cost-effective compared to other materials?

- Steel channels are generally considered to be a cost-effective option when compared to other materials. This is due to the fact that steel is widely available and relatively inexpensive. As a result, steel channels are often chosen for construction and manufacturing projects as they provide good value for money. Not only that, but steel channels also offer exceptional strength and durability, enabling them to withstand heavy loads and harsh conditions. This durability leads to long-term cost savings, as steel channels require less maintenance and replacement compared to alternative materials. Moreover, steel is highly recyclable, making it an environmentally friendly choice. Although the initial cost of steel channels may be slightly higher than some other materials, their long-term cost-effectiveness and numerous benefits make them a popular option in various industries.

- Q: What are the different shapes available for steel channels?

- Steel channels, also known as C-channels or U-channels, come in a variety of shapes to suit different applications and requirements. The most common shapes available for steel channels include: 1. Standard Channels: These are the most widely used and commonly available steel channels. They have a C-shaped cross-section, with equal flanges that are parallel to each other. Standard channels are often used for structural applications, such as supporting beams or framing. 2. Back-to-Back Channels: Also known as double channels or double C-channels, these steel channels consist of two standard channels placed back-to-back and welded or bolted together. Back-to-back channels provide increased strength and rigidity, making them suitable for heavy-duty applications like racking systems or conveyor frames. 3. Tapered Channels: Tapered steel channels have unequal flanges, with one flange wider or thicker than the other. These channels are designed to distribute weight and load more efficiently, making them useful in applications where weight reduction or specific load-bearing capabilities are required. 4. Hat Channels: Hat channels, also known as C-purlins or Z-purlins, have a unique shape resembling the letter "H" or "Z". They are commonly used in construction for roof and wall framing, as well as in the automotive industry for reinforcing vehicle structures. Hat channels provide excellent strength and stiffness while minimizing weight. 5. Custom Shapes: In addition to the standard shapes mentioned above, steel channels can also be custom designed and fabricated to meet specific requirements. Custom shapes may include curved channels, perforated channels, or channels with special cut-outs or patterns, depending on the intended application. It is important to note that the availability of different shapes may vary depending on the manufacturer and the specific steel channel product line. Therefore, it is advisable to consult with a steel supplier or manufacturer to determine the range of shapes available for steel channels.

- Q: What is the difference between channel steel and angle steel?

- The upper and lower leg channel width is equal, the section is in a groove shape, said channel specification method is based on the height (mm) (mm) * * legs wide waist thickness (mm) in the form of a rectangular section angle is basically the same, on both sides of the thickness and width of steel, steel specifications method is usually in terms of edge width * thick edge.

- Q: The two floor is made of channel steel barrier, but also want to do a toilet, just sitting and washbasin, so that the bathroom floor tiles can be it? What special treatment do you need? Ask designer friends for advice

- Do you can do is take the above channel, big core board, cement board and cover, the above can be waterproof, OK, or a steel plate surface anti slip can be waterproof, of course you can also consider tiling; what type of channel, the sewer pipe should not drain what problem that is how the toilet water row, if water is straight then you do not need to consider this question.

- Q: Can steel channels be used in modular construction?

- Indeed, steel channels find application in modular construction. Given their robustness, resilience, and adaptability, steel channels enjoy popularity as fundamental elements within modular construction. Their exceptional capacity for providing support and stability to modular structures enables them to endure varying loads and environmental circumstances. Moreover, the ease of fabrication and assembly of steel channels renders them suitable for the expeditious and efficient construction process demanded by modular construction. In summary, steel channels emerge as a dependable and effective option for modular construction endeavors.

Send your message to us

Q235 Hot Rolled Channel Steel With High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords