Hot Rolled Stainless Steel Coils,Cold Rolled Stainless Steel Coils Grade 304 Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

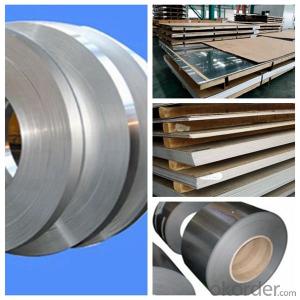

Hot Rolled Stainless Steel Coils,Cold Rolled Stainless Steel Coils Grade 304 Made in China

Products Description

Prodcut:Stainless Steel Coil

Thinckness: 0.20mm-8.0mm

Width:1000mm, 1219mm(4 feet), 1250mm, 1500mm, 1524mm(5 feet),

1800mm, 2000mm, 2200mm, 2500mm,and customizable

Ni:0.8~1.2% Cu:1.4~1.5% Cr:14

Standard: ASTM, JIS, GB, BS, DIN etc

Grade: 200series&300series&400series

Surface finish: 2B, BA, 8K, 6K, Mirror Finished, No1, No2, No4, Hair Line with PVC

Manufacture technology: cold rolled/hot rolled

Thickness Tolerance: +/-0.1mm

Width Tolerance: +/-10mm

200 Seriers: 201,202

300 Seriers: 301, 304, 304L, 316L, 309, 310S,321

400 Seriers: 410, 410S, 409L,430

Payment&Delivery

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

Detail picture of Products:

Application:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: How do you calculate the cost of a stainless steel sheet?

- Calculating the cost of a stainless steel sheet involves taking into account several factors. To begin, it is necessary to determine the dimensions of the sheet, including its length, width, and thickness. These measurements will dictate the amount of material required, which is a crucial aspect in determining the cost. Another factor to consider is the grade of the stainless steel sheet. Different grades, such as 304, 316, or 430, possess distinct properties and are associated with varying costs. The specific grade necessary for a particular application will influence the sheet's price. The finish of the stainless steel sheet is also important to consider. Options like brushed, polished, or patterned finishes all entail different processes and materials, which in turn impacts the cost. Additionally, the quantity of stainless steel sheets needed can affect the overall cost. Bulk orders are often eligible for discounted prices, while smaller quantities may incur higher expenses. Conducting thorough research on different suppliers is crucial. Prices can fluctuate depending on factors such as the supplier's location, reputation, and prevailing market conditions. Comparing prices among various suppliers is essential to obtain the most favorable cost. It is worth noting that there may be additional costs involved, such as transportation fees, handling charges, or cutting fees. It is advisable to inquire about these potential expenses when requesting quotes from suppliers. By taking these factors into consideration and conducting comprehensive research, it is possible to accurately calculate the cost of a stainless steel sheet.

- Q: Are stainless steel sheets resistant to pitting?

- Yes, stainless steel sheets are resistant to pitting. Stainless steel has a high resistance to corrosion, including pitting corrosion, due to its chromium content which forms a protective oxide layer on the surface. This makes stainless steel sheets a durable and reliable material for various applications where resistance to pitting is important.

- Q: What's the difference between cold rolled plate and stainless steel?

- The biggest difference between the stainless steel plate is the addition of 13% chromium (Cr) elements and even nickel elements (such as the standard 304 stainless steel, chromium containing 18%, nickel containing 9%) during steelmaking, thus having the function of stainless steel

- Q: Are stainless steel sheets suitable for marine applications?

- Stainless steel sheets are indeed a great choice for marine applications. The reason lies in their remarkable resistance to corrosion, which makes them perfect for use in marine environments where exposure to saltwater and other harsh elements is common. These sheets are equipped with a protective oxide layer that prevents any rust or corrosion, ensuring their long-lasting and sturdy nature in marine applications. Moreover, stainless steel sheets possess exceptional strength and impact resistance, making them capable of enduring the severe conditions and stresses encountered in marine environments. As a result of their corrosion resistance, durability, and strength, stainless steel sheets have gained immense popularity in the marine industry.

- Q: Are stainless steel sheets suitable for architectural mesh or screens?

- Yes, stainless steel sheets are highly suitable for architectural mesh or screens. They possess excellent durability, corrosion resistance, and aesthetic appeal, making them ideal for various architectural applications. Additionally, stainless steel sheets offer flexibility in design, allowing for intricate patterns and shapes in architectural mesh or screens.

- Q: Are stainless steel sheets suitable for chemical storage tanks?

- Indeed, chemical storage tanks can indeed be constructed using stainless steel sheets. Stainless steel is renowned for its exceptional resistance to corrosion and its remarkable durability, rendering it an ideal choice for the storage of various chemicals. It possesses the ability to withstand the corrosive effects of numerous substances, including acids, alkalis, and solvents, which are commonly stored in such tanks. Moreover, stainless steel sheets possess a high strength-to-weight ratio, enabling the construction of tanks capable of withstanding the immense pressure and weight of the chemicals. Furthermore, stainless steel is effortless to clean and maintain, making it a highly sanitary option for chemical storage. All in all, stainless steel sheets are a dependable and appropriate material for chemical storage tanks.

- Q: Are stainless steel sheets suitable for water tanks?

- Stainless steel sheets are indeed a great option for water tanks. Their resistance to corrosion makes them perfect for water storage. They won't react with the water or introduce any harmful substances into it. Additionally, stainless steel tanks are durable, require little maintenance, and have a long lifespan. They can handle high temperatures and extreme weather conditions without compromising their structural integrity. Moreover, stainless steel is non-porous, preventing the growth of bacteria and algae. These outstanding characteristics make stainless steel sheets a superb choice for water tanks in different settings, such as residential, commercial, and industrial environments.

- Q: How do I choose the appropriate gauge for stainless steel sheets?

- When choosing the appropriate gauge for stainless steel sheets, there are a few factors to consider. Firstly, you need to determine the application or purpose of the stainless steel sheets. Different gauges are suitable for specific uses. For example, thinner gauges (higher numbers) such as 26 or 28 are often used for decorative purposes, while thicker gauges (lower numbers) like 14 or 16 are more suitable for industrial applications that require durability and strength. Secondly, consider the environment in which the stainless steel sheets will be used. If the sheets will be exposed to harsh conditions, such as high temperatures, corrosive chemicals, or heavy impact, it is advisable to choose a thicker gauge to ensure the sheets can withstand these conditions. Additionally, the size and shape of the stainless steel sheets should be taken into account. Larger sheets or those with complex shapes may require thicker gauges to prevent bending or warping. Lastly, budget constraints may also play a role in the gauge selection. Thicker gauges generally cost more than thinner ones, so it is important to find a balance between the desired strength and the available budget. In summary, to choose the appropriate gauge for stainless steel sheets, consider the application, environmental conditions, sheet size and shape, and budget. It is also recommended to consult with a professional or supplier who can provide guidance based on your specific needs.

- Q: Are stainless steel sheets suitable for marine environments?

- Indeed, stainless steel sheets prove to be appropriate for marine environments. The remarkable resistance of stainless steel to corrosion and rust is attributed to the inclusion of chromium in its composition. Consequently, this renders it an exceptional material for utilization in marine environments, where consistent exposure to saltwater and moisture notoriously accelerates the corrosion of alternative metals. Moreover, stainless steel sheets possess commendable mechanical properties, high strength, and exceptional durability, further establishing their suitability for marine applications. Additionally, stainless steel exhibits ease of cleaning and maintenance, guaranteeing prolonged longevity and unwavering performance amidst harsh marine conditions.

- Q: What are the different types of stainless steel sheet textures available?

- There are several different types of stainless steel sheet textures available, each offering a unique aesthetic and functional appeal. Some of the commonly used textures include: 1. Brushed: This texture is achieved by brushing the stainless steel surface with abrasive materials in a unidirectional pattern. It creates a smooth, satin-like finish that is commonly seen in kitchen appliances and decorative applications. 2. Mirror: As the name suggests, this texture creates a highly reflective and mirror-like surface. It is achieved by polishing the stainless steel sheet using progressively finer abrasive materials until a reflective finish is obtained. Mirror-textured stainless steel sheets are often used in architectural and decorative applications. 3. Embossed: This texture involves imprinting patterns or designs onto the stainless steel sheet using embossing rollers. The raised patterns add depth and visual interest to the surface, making it a popular choice for interior design applications such as wall cladding or elevator panels. 4. Perforated: This texture involves creating a pattern of holes or perforations on the stainless steel sheet. It allows for the passage of light, air, or liquids while adding a decorative element to the surface. Perforated stainless steel sheets are commonly used in architectural, interior design, and filtration applications. 5. Etched: This texture is achieved by chemically etching the stainless steel surface using acid or other corrosive substances. The etching process creates a pattern or design on the surface, resulting in a visually appealing, textured finish. Etched stainless steel sheets are often used in decorative applications such as signage, elevator doors, or wall panels. 6. Hammered: This texture involves using hammers or other tools to create a hammered or dimpled pattern on the stainless steel sheet. It adds a rustic, textured look to the surface and is commonly used in architectural and decorative applications. These are just a few examples of the different types of stainless steel sheet textures available. Depending on the desired aesthetic and functional requirements, there are various other textures and finishes that can be applied to stainless steel sheets to achieve different looks and effects.

Send your message to us

Hot Rolled Stainless Steel Coils,Cold Rolled Stainless Steel Coils Grade 304 Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords