Hot Rolled S45C, C45, S50C Steel Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

S45C / C45 / S50C steel sheets description :

1.Main application

For plastic moulds, cold work die and mould base as well as constructional part

2.Manufacturers

An Steel, Wuyang Steel, Xiang Steel, Liu Steel, Bao Steel, etc.

3.Delivery condition

Hot rolling

Hardness: annealed HB≤210

Diameter: 12~500mm Length:1800~12000mm

4.General

High quality carbon constructional steel

5.Chemical analysis

Grade | C% | Mn% | Si% | P | S |

S45C | 0.42~0.48 | 0.6~0.9 | 0.15~0.35 | ≤0.030 | ≤0.030 |

6.Delivery

Acc. to your request—Standard steel bar(sawing)

——non-standard steel bar(sawing)

or Mill deliver condition,without sawing or cutting

7.Compared grades(based on usage):

Chinese | American | German | Japanese |

| GB | AISI | DIN | JIS |

| 45# | 1045 | 1.1191 | S45C |

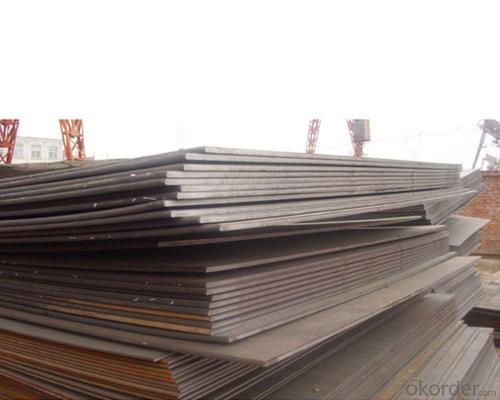

Product show

Workshop show

Shipping

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

Payment Terms

1.Payment: T/T, L/C, Western Union, MoneyGram,PayPal; 30% deposits; 70% balance before delivery.

2.MOQ: 1pcs

3.Warranty : 3 years

4.Package Informations: 1) EXPORT, In 20 feet (GW 25 ton) or 40 feet Container (GW 25 ton)

2)as customer's requirement

Why choose us?

(1) The leading exporter in China special steel industry.

(2) Large stocks for various sizes, fast delivery date.

(3) Good business relationship with China famous factories.

(4) More than 7 years steel exporting experience.

(5) Good after-sales service guarantee.

- Q: How does stainless steel contribute to the construction industry?

- Stainless steel contributes to the construction industry by providing durability, corrosion resistance, and aesthetic appeal. It is widely used in structural applications, such as building facades, bridges, and roofing, as it can withstand harsh weather conditions and maintain its strength over time. Stainless steel's resistance to corrosion also makes it a suitable choice for plumbing, electrical, and HVAC systems, ensuring longevity and minimizing maintenance. Additionally, its sleek and modern appearance enhances the overall aesthetics of architectural designs.

- Q: How does special steel contribute to the energy storage sector?

- Special steel plays a crucial role in the energy storage sector by providing essential components for various energy storage systems. One significant application of special steel is in the manufacturing of batteries, which are essential for storing energy in various forms. Special steel is ideal for battery casings and frames due to its high strength, excellent corrosion resistance, and durability. Battery casings made from special steel can withstand high pressures and protect the internal components from external impacts, ensuring the safety and reliability of the entire energy storage system. Furthermore, special steel is utilized in the production of electrodes, a critical component of batteries. Electrodes require materials that can efficiently conduct electricity while enduring repeated charge and discharge cycles. Special steel, such as stainless steel, possesses excellent electrical conductivity and can withstand the demanding conditions within batteries, making it an ideal choice for electrode manufacturing. Additionally, special steel is employed in the construction of infrastructure for energy storage systems. Steel structures are used to support large-scale energy storage devices like pumped hydro storage facilities and compressed air energy storage systems. These structures must be strong, durable, and resistant to environmental conditions. Special steel provides the necessary strength and corrosion resistance to ensure the longevity and reliability of these energy storage infrastructure projects. In summary, special steel contributes significantly to the energy storage sector by providing essential components for batteries, such as casings and electrodes. It also plays a vital role in the construction of infrastructure for energy storage systems. With its exceptional properties, special steel enhances the safety, efficiency, and durability of energy storage technologies, thereby facilitating the growth and advancement of the renewable energy sector as a whole.

- Q: What are the requirements for special steel used in telecommunications equipment manufacturing?

- The requirements for special steel used in telecommunications equipment manufacturing can vary depending on the specific application and intended use. However, there are certain general requirements that are commonly sought after in this industry. Firstly, the special steel used in telecommunications equipment manufacturing should possess excellent mechanical properties, including high strength, toughness, and durability. This is crucial as telecommunications equipment often needs to withstand harsh weather conditions, extreme temperatures, and various environmental factors while maintaining its structural integrity. Secondly, the steel should have excellent corrosion resistance properties. Telecommunications equipment is often installed outdoors or in environments with high humidity, saltwater exposure, or chemical pollutants, which can lead to corrosion. Therefore, the special steel used in manufacturing such equipment should be resistant to corrosion to ensure longevity and reliable performance. Another important requirement is electromagnetic compatibility (EMC). Telecommunications equipment operates in an environment with various electrical and electromagnetic signals. The steel used should possess good electrical conductivity and magnetic permeability to minimize interference and maintain signal integrity. Additionally, the special steel used in telecommunications equipment manufacturing should have good thermal conductivity properties. This is important to dissipate heat generated during operation, preventing overheating and ensuring the equipment's reliability. Furthermore, the steel should be easily machinable and weldable to facilitate the manufacturing process. Ease of fabrication and forming is crucial to meet the specific design requirements of telecommunications equipment. Lastly, compliance with industry standards and regulations is essential. The special steel used in telecommunications equipment manufacturing should meet the relevant international standards and certifications to ensure safety, quality, and compatibility with other components in the telecommunication network. In summary, the requirements for special steel used in telecommunications equipment manufacturing include excellent mechanical properties, corrosion resistance, electromagnetic compatibility, thermal conductivity, machinability, and compliance with industry standards. Meeting these requirements ensures the production of high-quality and reliable telecommunications equipment.

- Q: What are the different methods of preventing hydrogen embrittlement in special steel?

- Preventing hydrogen embrittlement in special steel can be achieved through various methods. Firstly, selecting the appropriate steel type that has a lower susceptibility to embrittlement is an effective preventive measure. Opting for steels with lower alloy content or different composition can be advantageous, as high strength and hardness can make steels more prone to embrittlement. Controlled heat treatment is another method that can reduce the risk of hydrogen embrittlement. Tempering and annealing at specific temperatures can relieve internal stresses and minimize the impact of hydrogen absorption. To prevent or reduce the amount of hydrogen in the steel, hydrogen mitigation techniques can be utilized. These techniques include preheating the steel before hydrogen exposure, implementing desorption methods like vacuum annealing to remove trapped hydrogen, and using hydrogen scavenger coatings or inhibitors to capture or neutralize hydrogen. Stress reduction is crucial in preventing hydrogen embrittlement. Implementing stress relief techniques such as shot peening or stress-relieving heat treatments can significantly reduce the potential for embrittlement. Proper handling and storage of the steel are also important. It is vital to protect the steel from hydrogen-rich environments during manufacturing, handling, or storage stages. This can be achieved through careful consideration of cleaning or pickling processes, appropriate packaging, and storage techniques such as using dry environments or protective coatings. Regular maintenance and inspection of steel components are essential to identify signs of hydrogen embrittlement at an early stage. This allows for timely repairs or replacements to prevent catastrophic failures. It is important to note that the specific methods employed to prevent hydrogen embrittlement may vary depending on the application, type of steel, and environmental conditions. Consulting with experts and adhering to industry standards and guidelines are crucial to ensure effective prevention of hydrogen embrittlement in special steel.

- Q: What are the main advantages of using special steel in the defense industry?

- The main advantages of using special steel in the defense industry are its exceptional strength, durability, and resistance to wear and tear. Special steel alloys can withstand extreme conditions, such as high temperatures and pressures, making them ideal for military applications. Additionally, special steel offers enhanced corrosion resistance, ensuring the longevity of defense equipment even in harsh environments. Its high impact resistance and ability to absorb shock also make it valuable in protecting soldiers and military vehicles. Overall, special steel provides crucial advantages in terms of reliability, performance, and protection for the defense industry.

- Q: What is the significance of vanadium in special steel?

- Due to its unique properties and effects on the performance of steel, vanadium is an important element in special steel. Special steel, which is designed for specific applications requiring strength, durability, and specific characteristics, benefits greatly from the inclusion of vanadium. One of the primary rationales behind using vanadium in special steel is its ability to increase the steel's strength and toughness. Vanadium forms robust carbides within the microstructure of the steel, which prevent grain growth and enhance its resistance to deformation and cracking. This makes the steel highly suitable for applications that demand exceptional strength, such as the construction of bridges, high-rise buildings, and machinery. In addition to strength, vanadium also improves the hardenability of the steel. Hardenability refers to the steel's capacity to be hardened through heat treatment methods like quenching and tempering. Vanadium enhances the hardenability of the steel, enabling easy achievement of desired properties like increased wear resistance and improved cutting performance. This makes vanadium-containing special steel ideal for tools, dies, and other applications requiring hardness and wear resistance. Furthermore, vanadium contributes to the steel's resistance to corrosion. It creates stable oxide layers on the steel's surface, acting as a protective barrier against corrosion and oxidation. This is particularly advantageous in harsh environments like marine environments or chemical processing plants. Moreover, vanadium also enhances the heat resistance and thermal stability of special steel. It helps the steel retain its strength and hardness even at high temperatures, making it suitable for applications involving high-temperature environments like aerospace components and automotive engine parts. In summary, the importance of vanadium in special steel lies in its ability to enhance the steel's strength, toughness, hardenability, corrosion resistance, and heat resistance. These properties make vanadium-containing special steel highly sought after in various industries that require exceptional performance and reliability.

- Q: How does special steel contribute to the dimensional stability of products?

- Special steel contributes to the dimensional stability of products through its unique properties and characteristics. One of the key factors is its high level of hardness, which allows it to resist deformation or changes in shape and size under varying temperature and load conditions. This hardness ensures that the product maintains its intended dimensions and shape, even when subjected to external forces or thermal fluctuations. Moreover, special steel often possesses excellent thermal conductivity, enabling it to efficiently distribute and dissipate heat. This property helps prevent localized heating or cooling, which can cause dimensional changes in materials. By maintaining consistent temperatures across the product, special steel minimizes the risk of warping, expansion, or contraction, thereby ensuring dimensional stability. Another aspect that contributes to dimensional stability is the low coefficient of thermal expansion of special steel. This coefficient measures the amount of expansion or contraction a material undergoes in response to temperature changes. Special steel's low coefficient means it experiences minimal dimensional changes when exposed to temperature variations. This characteristic is particularly crucial in applications where precise tolerances and tight dimensional control are required, such as in aerospace or automotive industries. Furthermore, special steel often possesses enhanced corrosion resistance, which helps prevent rusting or degradation of the material over time. Corrosion can lead to changes in the shape and dimensions of products, compromising their dimensional stability. By using special steel, manufacturers can ensure that their products maintain their original dimensions and structural integrity, even in harsh or corrosive environments. Overall, the unique properties of special steel, such as high hardness, excellent thermal conductivity, low coefficient of thermal expansion, and corrosion resistance, all contribute to the dimensional stability of products. By incorporating special steel into the manufacturing process, companies can produce high-quality products that maintain their precise dimensions and shape, ensuring reliability and longevity for end-users.

- Q: How does special steel perform in high-temperature mechanical fatigue conditions?

- Special steel, known for its high strength and resistance to heat, performs exceptionally well in high-temperature mechanical fatigue conditions. Its unique composition and properties enable it to withstand prolonged exposure to elevated temperatures without significant loss of mechanical integrity or performance. This makes special steel a reliable and durable material choice for applications that involve repetitive cyclic loading and heat exposure, such as in aerospace, power generation, and automotive industries.

- Q: How does special steel contribute to weight reduction in manufacturing?

- Special steel contributes to weight reduction in manufacturing through its unique properties and characteristics. Special steels are designed to have high strength-to-weight ratios, allowing manufacturers to use less material while still achieving the desired strength and performance. This results in lighter and more efficient products without compromising their structural integrity. Additionally, special steels can be processed into complex shapes, enabling the production of intricate components that are both lightweight and strong. Overall, the use of special steel in manufacturing helps reduce the overall weight of products, leading to improved fuel efficiency, lower transportation costs, and increased sustainability.

- Q: What are the common challenges in forging special steel?

- Common challenges in forging special steel include achieving the desired grain structure, maintaining uniformity and consistency throughout the material, controlling the temperature during the forging process, preventing cracks and defects, and ensuring proper heat treatment for the desired mechanical properties.

Send your message to us

Hot Rolled S45C, C45, S50C Steel Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords