Steel Flat Bar Hot Roll 5160 Medium Carbon Round Edge Spring

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

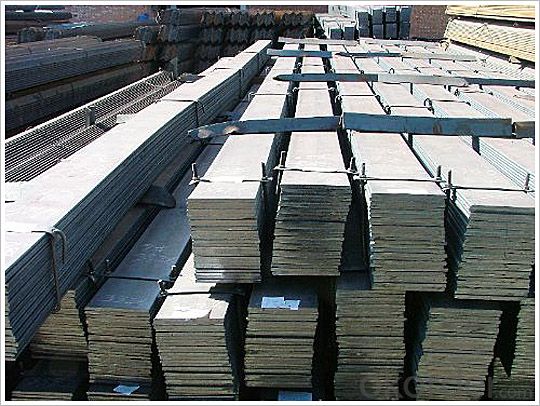

OKorder is offering Steel Flat Bar Hot Roll 5160 Medium Carbon Round Edge Spring at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Flat Bar Hot Roll 5160 Medium Carbon Round Edge Spring are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Flat Bar Hot Roll 5160 Medium Carbon Round Edge Spring are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Production Manufacturer | DAQIANG |

Product Name | Spring Steel Flat Bar |

Steel Type | Spring Steel |

Material | 5160 |

Others Available Material | 60Si2Mn, 5160H, SUP9, SUP9A, 55Cr3 etc. |

Thickness Range (mm) | 6-50 |

Width Range (mm) | 40-135 |

Usual length (mm) | 5800 |

Daily Capacity (Metric Ton) | 1000 |

Certificate | ISO9001: 2008 |

Edge | Round Edge / Right Angle |

Surface | None / Oil Protection |

Usage | Leaf Springs, Cultivator Blades, Garden Tools, Knifes etc. |

Samples | Free of Charge |

Chemical Composition (Common Material) | |||||||

C | Si | Mn | P | S | Cr | Cu | |

60Si2Mn | 0.56-0.64 | 1.5-2.0 | 0.7-1.0 | ≤0.035 | ≤0.035 | ≤0.35 | |

5160 | 0.56-0.64 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.04 | 0.7-0.9 | |

5160H | 0.55-0.65 | 0.15-0.35 | 0.65-1.1 | 0.6-1.0 | |||

SUP9 | 0.52-0.6 | 0.15-0.35 | 0.65-0.95 | ≤0.03 | ≤0.03 | 0.65-0.95 | ≤0.3 |

SUP9A | 0.56-0.64 | 0.15-0.35 | 0.7-1.0 | ≤0.03 | ≤0.03 | 0.7-1.0 | ≤0.3 |

55Cr3 | 0.52-0.59 | ≤0.4 | 0.7-1.0 | ≤0.025 | ≤0.025 | 0.7-1.0 | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: How do steel flat bars contribute to the overall stability of a structure?

- Steel flat bars contribute to the overall stability of a structure by providing strength and rigidity. Due to their flat shape, they offer excellent load-bearing capacity and resistance against bending or twisting forces. These bars can be strategically placed throughout the structure, serving as support beams, braces, or reinforcements to distribute and minimize the impact of external loads. Their high tensile strength and durability make them essential components in various construction applications, enhancing the overall stability and structural integrity of buildings, bridges, and other infrastructures.

- Q: Can steel flat bars be used for structural applications?

- Yes, steel flat bars can be used for structural applications. Steel flat bars are versatile and can provide structural support in various construction projects. They are commonly used in the construction of buildings, bridges, and other infrastructure. Their flat and wide shape makes them suitable for load-bearing purposes, such as beams, braces, and framing elements. Additionally, steel flat bars offer excellent strength and durability, making them capable of withstanding heavy loads and structural stresses. They can also be easily welded, bolted, or attached to other structural components, allowing for efficient and precise construction. Overall, steel flat bars are a reliable choice for structural applications due to their strength, versatility, and ease of use.

- Q: The minus sign in front of what 40 galvanized flat steel

- Also called hot galvanized and hot dip galvanizing: hot dip galvanizing is an effective way of metal corrosion, mainly used for metal structure on the facilities of the industry. The steel piece after being cleaned is dipped into the molten zinc liquid at about 500 DEG C so that the zinc coating is adhered on the surface of the steel member so as to prevent corrosion.

- Q: Are steel flat bars commonly used in the construction of transportation facilities?

- Yes, steel flat bars are commonly used in the construction of transportation facilities. Steel flat bars are versatile and strong, making them suitable for various applications in transportation infrastructure. They can be used for framing structures, reinforcing concrete, or as support beams in bridges and highways. Steel flat bars provide excellent load-bearing capacity and resistance to bending, making them an ideal choice for constructing transportation facilities that need to withstand heavy loads and harsh weather conditions. Additionally, steel flat bars are readily available in different sizes and can be easily fabricated to meet specific design requirements, making them a preferred material in the construction industry.

- Q: Are steel flat bars available in different grades and alloys?

- Yes, steel flat bars are available in various grades and alloys.

- Q: Can steel flat bars be used for making storage racks?

- Yes, steel flat bars can be used for making storage racks. Steel flat bars are strong and durable, making them suitable for supporting heavy loads in storage rack structures.

- Q: Do I need to make the ring galvanized flat steel ground connection between the electric well and the distribution room?

- There are two forms, one, as you say, because the distribution room has high voltage equipment and cables, and the total equipotential balance is uneven. Repeated earthing of the equipment is required.

- Q: What do the numbers in the steel HN346*174*6*9 refer to?

- Small steel: small steel, middle, round, square, flat steel processing and use, similar to large steel, small diameter round steel is often used as building steel.

- Q: Are steel flat bars suitable for making storage racks?

- Steel flat bars are a suitable option for constructing storage racks due to their strength, durability, and versatility. These bars are known for their ability to withstand heavy loads, making them capable of securely holding and supporting heavy objects. Moreover, they have a resistance to bending and warping, guaranteeing the long-lasting nature of the storage racks. Additionally, steel flat bars are easily manipulated and can be welded or bolted together to create customized racks that cater to specific storage requirements. Ultimately, steel flat bars offer a dependable and robust framework for storage racks, making them a favored choice in a variety of industries and environments.

- Q: Do steel flat bars have a specific melting point?

- Yes, steel flat bars do have a specific melting point. The melting point of steel typically ranges between 1370°C to 1530°C (2500°F to 2800°F), depending on the specific composition and type of steel.

Send your message to us

Steel Flat Bar Hot Roll 5160 Medium Carbon Round Edge Spring

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords