Hot Rolled,Cold Rolled Stainless Steel Coils,Steel Plates NO,1 Finish,NO.2B Finish Steel Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

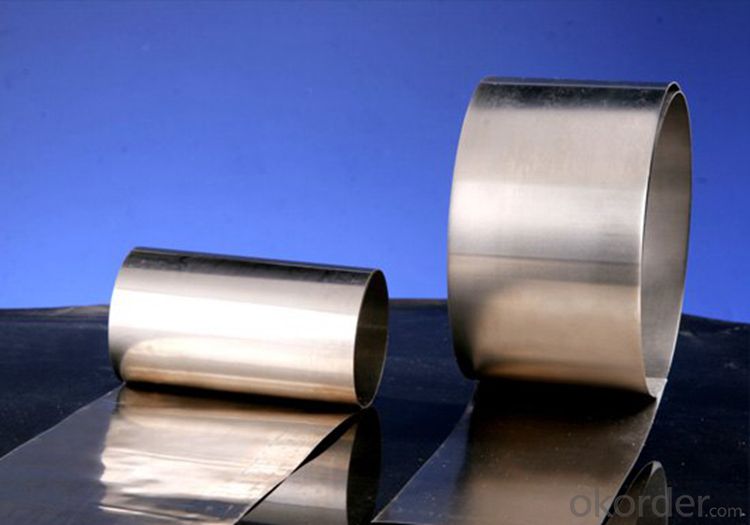

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

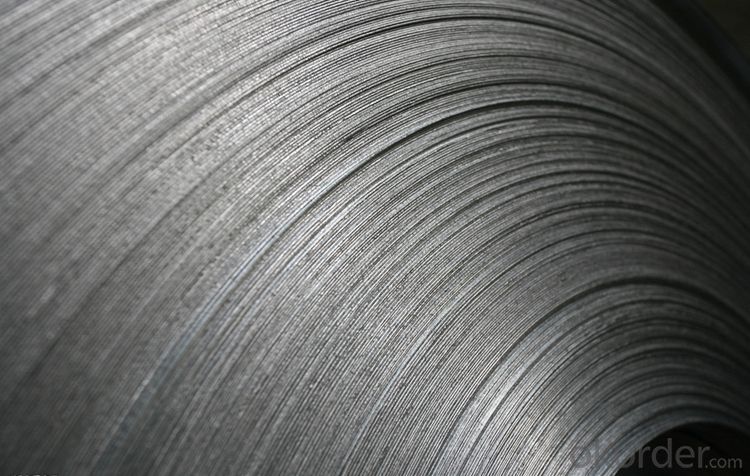

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy | ||

Delivery Time | With 30-40 days after deposit | ||

Packaging & Delivery

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Detail picture of Products:

Application:

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Can stainless steel sheets be used for elevator floors?

- Indeed, elevator floors can indeed make use of stainless steel sheets. Known for its durability and resistance to corrosion, stainless steel is widely employed in numerous fields, including elevator interiors. Elevator floors adorned with stainless steel sheets exude a sophisticated and contemporary aesthetic, all while effectively withstanding scratches, blemishes, and impacts. Moreover, stainless steel's effortless cleanliness and maintenance make it an ideal selection for elevator floors that endure substantial foot traffic.

- Q: What are the different finishes available for stainless steel sheets?

- There are several different finishes available for stainless steel sheets, each offering a unique look and level of protection. 1. No. 1 Finish: This is the most common and basic finish for stainless steel sheets. It is a hot-rolled finish that appears dull and rough, with visible grain lines. It is typically used for industrial applications where appearance is not a major concern. 2. No. 2B Finish: This is a bright, cold-rolled finish that is slightly reflective. It has a smooth surface with a matte finish and is commonly used for decorative purposes, such as in architectural applications or for kitchen appliances. 3. No. 4 Finish: Also known as brushed or satin finish, it has a fine polishing grit line that creates a distinctive look. This finish is often used for decorative applications, such as for elevator doors or trim, and can hide minor surface imperfections. 4. No. 8 Mirror Finish: This is the most reflective finish available for stainless steel sheets. It has a highly polished, mirror-like surface that is smooth and shiny. This finish is often used for decorative purposes, such as in architectural features or decorative trim. 5. Hairline Finish: This finish features a very fine, brushed texture that is similar to the grain of hair. It provides a subtle, elegant appearance and is commonly used for decorative and architectural applications. 6. Embossed Finish: This finish involves creating a pattern or design on the surface of the stainless steel sheet through embossing or stamping. It adds texture and visual interest to the sheet and is often used for decorative purposes. It is important to note that the availability of these finishes may vary depending on the supplier and the specific stainless steel grade being used.

- Q: What is the thickness range of stainless steel sheets?

- The thickness range of stainless steel sheets can vary depending on the specific grade and application. However, typically stainless steel sheets are available in thicknesses ranging from 0.4mm to 6mm. Additionally, there are specialized stainless steel sheets available in thinner gauges, such as foil sheets that can be as thin as 0.02mm. On the other hand, for heavy-duty applications, stainless steel sheets can be as thick as 50mm or more. Ultimately, the desired thickness of a stainless steel sheet will depend on the intended use, structural requirements, and aesthetic preferences.

- Q: Are stainless steel sheets resistant to pitting corrosion?

- Yes, stainless steel sheets are resistant to pitting corrosion. Pitting corrosion is a localized form of corrosion that occurs in specific areas, resulting in small pits or holes on the metal surface. Stainless steel sheets are made with a high percentage of chromium, which forms a passive oxide layer on the surface, providing excellent resistance to corrosion. This oxide layer acts as a barrier, protecting the metal from pitting corrosion. Additionally, stainless steel contains other alloying elements such as nickel and molybdenum, which further enhance its resistance to pitting corrosion. Therefore, stainless steel sheets are highly resistant to pitting corrosion and are commonly used in applications where corrosion resistance is crucial, such as in the construction, automotive, and food processing industries.

- Q: How do I prevent corrosion under insulation on stainless steel sheets?

- To prevent corrosion under insulation on stainless steel sheets, there are several steps you can take: 1. Proper insulation selection: Choose insulation materials that are compatible with stainless steel and have a low water absorption rate. Avoid using materials that can cause galvanic corrosion when in contact with stainless steel. 2. Adequate insulation thickness: Ensure that the insulation thickness is sufficient to prevent moisture condensation on the stainless steel surface. Condensation can trap moisture and accelerate corrosion. Consult with an insulation specialist to determine the appropriate thickness for your specific application. 3. Vapor barriers: Install vapor barriers between the insulation and the stainless steel sheets. Vapor barriers act as a moisture barrier, preventing the ingress of water or moisture that can lead to corrosion. These barriers can be made of materials such as foil or plastic films. 4. Proper installation: Ensure that the insulation is properly installed, with no gaps or areas where moisture can accumulate. Pay close attention to joints, seams, and connections, making sure they are tightly sealed to prevent water penetration. 5. Regular inspection and maintenance: Regularly inspect the insulation system to identify any signs of damage, such as leaks or deterioration. Promptly repair any damaged insulation or vapor barriers to prevent moisture from reaching the stainless steel surface. 6. Ventilation: Provide adequate ventilation to prevent moisture buildup in enclosed spaces. Good airflow can help reduce the chances of condensation and subsequent corrosion. 7. Cathodic protection: Consider using cathodic protection methods, such as sacrificial anodes or impressed current systems, to protect stainless steel sheets from corrosion. These methods create an electrical current that counteracts the corrosion process, extending the lifespan of the stainless steel. Remember, it is essential to consult with corrosion specialists or insulation experts to ensure the best practices are implemented for your specific application and environment.

- Q: What is the difference between stainless steel sheets and regular steel sheets?

- The composition and properties of stainless steel sheets and regular steel sheets are different. Stainless steel sheets are primarily made of iron and contain at least 10.5% chromium, which gives them their unique stainless properties. On the other hand, regular steel sheets are primarily made of iron and carbon, without any significant amount of chromium. The presence of chromium in stainless steel sheets provides several advantages. Firstly, it enhances the material's corrosion resistance, making it highly resistant to rust and staining. This makes stainless steel sheets suitable for applications in environments where moisture or exposure to corrosive substances is a concern, such as in the food and beverage industry or marine applications. Additionally, stainless steel sheets have excellent heat resistance, making them suitable for high-temperature applications. They can withstand extreme temperatures without losing their structural integrity, which may not be the case for regular steel sheets. The appearance of the two materials also differs. Stainless steel sheets have a bright, reflective surface due to their chromium content, giving them a lustrous and modern look. On the other hand, regular steel sheets have a duller and less polished appearance. Furthermore, stainless steel sheets are often more expensive than regular steel sheets due to additional manufacturing processes and the higher cost of the chromium alloy. However, the enhanced corrosion resistance and durability provided by stainless steel sheets can often justify the higher cost in various applications. In conclusion, stainless steel sheets differ from regular steel sheets in terms of composition, properties, appearance, and cost. Stainless steel sheets offer superior corrosion resistance, heat resistance, and a visually appealing surface, making them ideal for specific applications where these attributes are required. Regular steel sheets, on the other hand, are more affordable but lack the unique properties of stainless steel.

- Q: Can stainless steel sheets be used for chemical mixing tanks?

- Yes, stainless steel sheets can be used for chemical mixing tanks. Stainless steel is a popular choice for chemical mixing tanks due to its excellent corrosion resistance and durability. It is resistant to a wide range of chemicals and can withstand high temperatures, making it suitable for various chemical mixing applications. Stainless steel sheets are easy to clean and maintain, ensuring the purity of the mixed chemicals. Additionally, stainless steel is non-reactive, which means it does not interact with the chemicals being mixed, ensuring the integrity of the mixture. Overall, stainless steel sheets are a reliable and efficient material choice for chemical mixing tanks.

- Q: What are the different types of perforations available for stainless steel sheets?

- There are several different types of perforations available for stainless steel sheets, each serving a specific purpose and offering unique characteristics. Here are some of the most common types: 1. Round Perforations: These are the most basic and widely used type of perforations. They consist of evenly spaced round holes punched through the stainless steel sheet. Round perforations offer good airflow and visibility while providing adequate strength and durability. 2. Square Perforations: Similar to round perforations, square perforations feature evenly spaced square holes instead of round ones. Square perforations are often preferred when a more geometric and modern aesthetic is desired, as they can create a visually appealing pattern. 3. Slotted Perforations: Slotted perforations are characterized by elongated, rectangular holes that are punched through the stainless steel sheet. This type of perforation allows for better drainage and airflow, making it suitable for applications such as grilles, screens, and filters. 4. Hexagonal Perforations: Hexagonal perforations feature hexagon-shaped holes that are punched through the stainless steel sheet. This type of perforation offers an interesting visual pattern and can provide better strength and rigidity compared to round or square perforations. 5. Decorative Perforations: These perforations are specifically designed to enhance the aesthetic appeal of stainless steel sheets. They can come in various shapes, sizes, and patterns, including floral, geometric, or custom designs. Decorative perforations are often used in architectural applications, interior design, and decorative panels. 6. Micro Perforations: Micro perforations are extremely small holes that are closely spaced in the stainless steel sheet. They are commonly used in applications where a high level of precision and fine filtering is required, such as speaker grilles, ventilation systems, or sieves. It's important to note that the availability of specific perforation types may vary depending on the supplier or manufacturer. Additionally, some suppliers may offer custom perforation options to meet unique requirements or design preferences.

- Q: Are stainless steel sheets fire resistant?

- Stainless steel sheets have excellent fire resistance properties. Due to their high melting point and low thermal conductivity, stainless steel is able to withstand high temperatures for prolonged periods of time without undergoing significant structural changes or losing their strength. This makes stainless steel sheets highly resistant to fire and heat damage. Additionally, stainless steel does not release toxic fumes when exposed to fire, which further enhances its safety in fire-prone environments. As a result, stainless steel sheets are commonly used in applications where fire resistance is a critical requirement, such as in the construction of fire doors, fire escapes, and fire-resistant enclosures.

- Q: How do you prevent intergranular corrosion in stainless steel sheets?

- To prevent intergranular corrosion in stainless steel sheets, several methods can be employed. First, the selection of the appropriate stainless steel grade is essential. Grades with a low carbon content, such as 304L or 316L, are less susceptible to intergranular corrosion compared to higher carbon grades. This is due to their ability to minimize the formation of chromium carbide precipitates, which are the main cause of intergranular corrosion. Another method is heat treatment. Processes like solution annealing and quenching can help eliminate or reduce the formation of chromium carbide precipitates. By dissolving existing precipitates and promoting the formation of a protective chromium oxide layer on the surface, the corrosion resistance of the stainless steel is restored. Careful attention must also be given to welding techniques when working with stainless steel sheets. Processes like gas tungsten arc welding (GTAW) or laser welding, which provide precise control over heat input, are preferred. It is also advisable to use low carbon filler metals or consumables specifically designed for intergranular corrosion resistance to minimize the risk of corrosion. After welding, thorough cleaning of the welded area is crucial to remove any contaminants or oxide scales that could promote corrosion. Acid cleaning followed by passivation helps restore the protective oxide layer and enhances the stainless steel's resistance to intergranular corrosion. Lastly, it is important to avoid sensitization, which occurs when stainless steel is exposed to high temperatures for extended periods. Prolonged exposure to temperatures between 450-850°C (842-1562°F) during fabrication or service should be avoided to prevent sensitization and subsequent intergranular corrosion. By implementing these preventive measures, intergranular corrosion in stainless steel sheets can be effectively minimized, ensuring the longevity and performance of the material in various applications.

Send your message to us

Hot Rolled,Cold Rolled Stainless Steel Coils,Steel Plates NO,1 Finish,NO.2B Finish Steel Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords