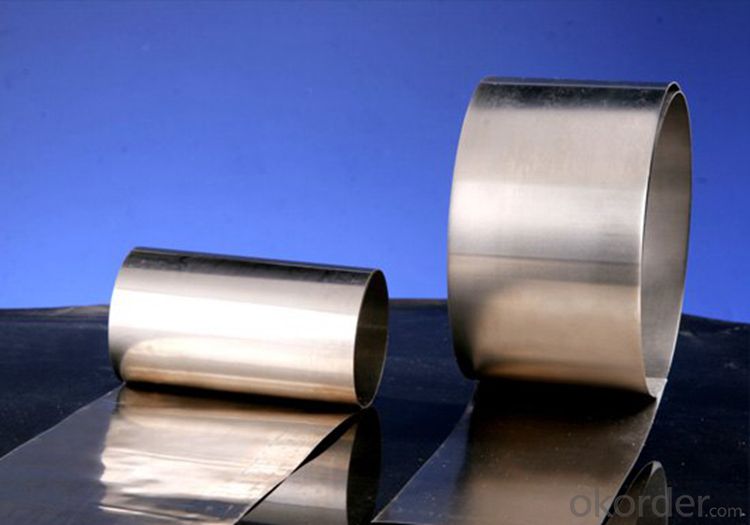

Hot Rolled Stainless Coils,Cold Rolled Stainless Coils,NO.1 Finishe,NO.2B Finish Steel Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

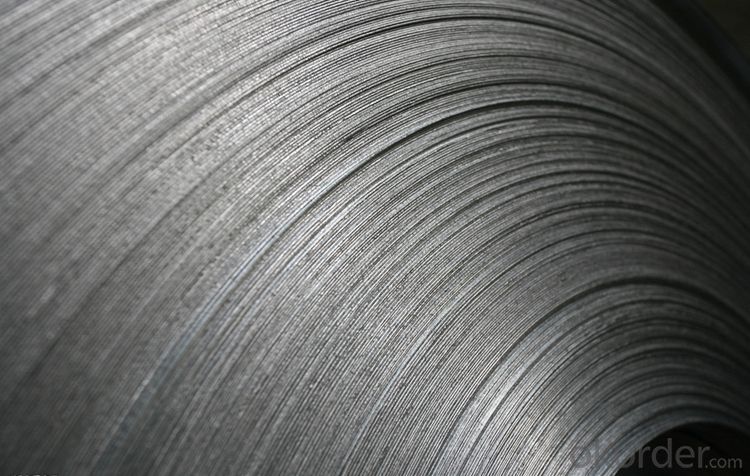

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy | ||

Delivery Time | With 30-40 days after deposit | ||

Packaging & Delivery

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Detail picture of Products:

Application:

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: How do you measure the thickness of stainless steel sheets?

- There are multiple methods available for measuring the thickness of stainless steel sheets. One commonly used approach involves the utilization of a caliper, which is a precision measuring tool. By placing the jaws of the caliper on both sides of the sheet and tightening them until contact is made, the thickness can be directly measured. The reading on the caliper will provide an indication of the sheet's thickness. Alternatively, a more accurate method for measuring very thin sheets is through the use of a micrometer, which functions similarly to a caliper. By employing a spindle and anvil, the micrometer can provide precise measurements of thickness. This method is frequently employed in industries where accuracy is of utmost importance, such as manufacturing and engineering. In the absence of a caliper or micrometer, a simple ruler or tape measure can be utilized. Although this method may not provide the same level of accuracy as specialized tools, it can still offer a rough estimate of the thickness. By measuring the height of the sheet, assuming it is uniformly thick, one can infer the sheet's thickness. It is worth noting that the appropriate measurement tool depends on the thickness of the stainless steel sheet. Micrometers and calipers are best suited for measuring thinner sheets, while thicker sheets may require more specialized instruments like ultrasonic thickness gauges. In conclusion, the thickness of stainless steel sheets can be measured using various methods, including calipers, micrometers, rulers, or tape measures. The choice of tool depends on the desired level of accuracy and the thickness of the sheet being measured.

- Q: Welding defects analysis of 1.5mm stainless steel plate

- UndercutReasons: 1. The welding parameters do not choose U, I is too large, the welding speed is too slow.The arc is too long. The molten metal failed to fill the melting gap in time.Hazard: the working cross section of base metal decreases and the stress concentration at the undercut is concentrated.

- Q: Are stainless steel sheets suitable for medical implants?

- Yes, stainless steel sheets are suitable for medical implants. Stainless steel is commonly used in medical implants due to its excellent corrosion resistance, mechanical strength, and biocompatibility. It can be easily sterilized, is durable, and has a long track record of successful use in various medical applications.

- Q: What are the standard sizes and thicknesses of stainless steel sheets?

- Stainless steel sheets come in various standard sizes and thicknesses that are widely used in different industries and applications. The standard sizes typically range from 4 feet by 8 feet to 5 feet by 10 feet, although custom sizes can also be obtained based on specific requirements. Regarding thicknesses, stainless steel sheets are available in several standard options, including 20 gauge (0.036 inches), 18 gauge (0.048 inches), 16 gauge (0.060 inches), 14 gauge (0.075 inches), 12 gauge (0.105 inches), and 10 gauge (0.135 inches). These thicknesses refer to the nominal thickness, and actual thickness may vary slightly. It is important to note that stainless steel sheets can also be obtained in metric sizes, with common thicknesses ranging from 0.5 mm to 3 mm. This allows for flexibility and compatibility with international standards and specifications. Overall, the standard sizes and thicknesses of stainless steel sheets are determined by industry standards and customer requirements, ensuring wide availability and versatility for various applications such as construction, automotive, aerospace, and kitchen equipment manufacturing, among others.

- Q: How do I prevent discoloration on stainless steel sheets?

- To avoid discoloration on stainless steel sheets, there are several steps you can take: 1. Keep them clean: Make sure to clean stainless steel sheets on a regular basis using mild soap or a dedicated stainless steel cleaner. Steer clear of abrasive cleaners or scrub brushes, as they can scratch the surface and make it more susceptible to discoloration. 2. Steer clear of harsh chemicals: Avoid using harsh chemicals, bleach, or cleaners containing chlorine on stainless steel sheets, as they can lead to discoloration. If any spills occur, clean them up immediately to prevent staining. 3. Ensure proper ventilation: It is crucial to have adequate ventilation in the area where the stainless steel sheets are installed. This is particularly important in spaces where chemicals or fumes are present, as they can react with the stainless steel and cause discoloration. 4. Apply protective coatings: Consider applying a protective coating to the stainless steel sheets to help prevent discoloration. There are various protective coatings available on the market that are specifically designed for stainless steel. These coatings create a barrier between the steel and external factors, reducing the likelihood of discoloration. 5. Perform regular maintenance: Regularly inspect the stainless steel sheets for any signs of discoloration or damage. Address any issues promptly to prevent further deterioration. By implementing these preventive measures, you can reduce the risk of discoloration on stainless steel sheets and maintain their aesthetic appeal for an extended period of time.

- Q: Can stainless steel sheets be used for cryogenic applications?

- Yes, stainless steel sheets can be used for cryogenic applications. Stainless steel is known for its excellent mechanical properties, corrosion resistance, and low thermal conductivity, which make it suitable for cryogenic environments. It can withstand the extreme cold temperatures without becoming brittle or losing its strength. Stainless steel sheets are commonly used in cryogenic applications such as storage tanks, piping systems, and cryogenic equipment. However, it is important to choose the appropriate grade of stainless steel that is specifically designed for cryogenic applications to ensure optimal performance and durability.

- Q: What are the standard dimensions for stainless steel sheets?

- The dimensions of stainless steel sheets differ based on the type and grade of stainless steel utilized. Nevertheless, there exist some widely available common sizes in the market. Typically, the standard width for most stainless steel sheets falls within the range of 36 to 48 inches, while the length can vary between 72 to 120 inches. These dimensions are commonly employed in construction, automotive, and manufacturing applications. The thickness of stainless steel sheets can also vary, with common choices ranging from 0.024 to 0.1875 inches. Thinner sheets are often used for decorative or lightweight purposes, whereas thicker sheets are utilized for heavy-duty applications requiring enhanced strength and durability. It is essential to note that these dimensions are general guidelines and may differ depending on specific project requirements. Moreover, custom sizes can be manufactured to meet the unique needs of a particular application. Overall, the standard dimensions for stainless steel sheets provide a range of options suitable for diverse industries and purposes. This ensures flexibility in selecting the appropriate size for a specific project.

- Q: Can stainless steel sheets be used for chemical reactors?

- Indeed, chemical reactors can indeed utilize stainless steel sheets. The utilization of stainless steel in chemical reactors is quite popular due to its remarkable resistance to corrosion. Its ability to resist chemical reactions with various substances is commendable, thus rendering it suitable for handling corrosive chemicals or environments. Moreover, stainless steel sheets are renowned for their durability, exceptional strength, and capacity to endure high temperatures. Hence, they are ideal for deployment in chemical reactors that may operate under extreme conditions. Furthermore, stainless steel is effortlessly maintainable and easy to clean, which is a pivotal factor in ensuring the purity and integrity of the reaction process. In conclusion, stainless steel sheets are widely employed in the construction of chemical reactors and are widely recognized as a trustworthy and efficient choice of material for this purpose.

- Q: Are stainless steel sheets suitable for outdoor sculptures or artwork?

- Yes, stainless steel sheets are highly suitable for outdoor sculptures or artwork. Stainless steel is known for its exceptional durability, corrosion resistance, and weather resistance, making it a perfect choice for outdoor installations. It can withstand harsh environmental conditions such as rain, snow, UV rays, and temperature fluctuations without losing its structural integrity or aesthetic appeal. Moreover, stainless steel can be easily shaped, cut, and welded, offering great flexibility for artists and designers to create intricate and complex sculptures. Additionally, stainless steel has a sleek and modern appearance, which can add a contemporary touch to any outdoor setting. Its low maintenance requirements and ability to retain its original finish for an extended period make it a cost-effective choice for outdoor sculptures or artwork. Therefore, stainless steel sheets are an excellent material option for creating long-lasting and visually appealing outdoor artworks.

- Q: What is the process of stainless steel mirror panel? What's the difference between them and stainless steel sand blasting plates?

- The 8K board, also called mirror panel, is polished on the surface of stainless steel by grinding fluid through polishing equipment, so that the surface of the plate is as clear as the mirror. Uses: mainly used in architectural decoration, elevator decoration, industrial decoration, facilities, decoration and other stainless steel products.

Send your message to us

Hot Rolled Stainless Coils,Cold Rolled Stainless Coils,NO.1 Finishe,NO.2B Finish Steel Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords