026 Aluminum Coil Hot Rolled Aluminium Circle AA3003 H14

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Hot Rolled Aluminium Circle is widly used in cooking pot field. There are two kinds of production method. One is hot rolled aluminium circle, the other is continuous casting aluminium circle. The mechanical for the two circle is different. If you will deep push, we recommend Hot rolled aluminium circle. If you just spinning, we recommend continuous casting aluminium circle.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

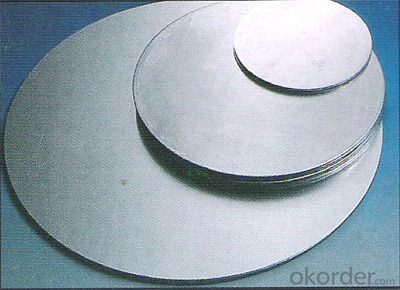

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Diemeter | Package |

| AA3003 | H14 | 0.2MM-3MM | 90MM-1200MM | Exportation Pallet |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What are the potential applications of coil-anodized aluminum coils?

- Coil-anodized aluminum coils have a wide range of potential applications due to their unique properties and advantages. Here are some of the key potential applications: 1. Architectural: Coil-anodized aluminum coils can be used in architectural applications such as cladding, roofing, and facades. The anodized coating provides enhanced durability, weather resistance, and color stability, making it suitable for exterior use in different climates. The coils can also be shaped and formed into various architectural elements, offering design flexibility. 2. Transportation: The lightweight nature of coil-anodized aluminum makes it ideal for transportation applications. It can be used for manufacturing parts and components in automotive, aerospace, and marine industries. The anodized coating enhances the corrosion resistance, making it suitable for exterior components and structures. 3. Electronics: Coil-anodized aluminum coils can be utilized in electronics manufacturing. The anodized coating provides excellent electrical insulation, which is crucial in applications requiring high conductivity and insulation. It can be used for manufacturing components like heat sinks, casings, and connectors. 4. Signage and displays: The vibrant and long-lasting colors obtained through coil-anodizing make it an ideal material for signage and displays. The anodized coating ensures color stability against UV radiation and harsh weather conditions, making it suitable for both indoor and outdoor applications. It allows for the creation of eye-catching and durable signage and displays. 5. Furniture and interior design: Coil-anodized aluminum coils can be used in the manufacturing of furniture and interior design elements. The anodized coating provides a smooth, durable, and scratch-resistant surface, making it suitable for applications like tables, chairs, wall panels, and decorative elements. The wide range of available colors and finishes allows for versatile design possibilities. 6. Industrial applications: Coil-anodized aluminum coils can find applications in various industrial sectors. The anodized coating provides enhanced corrosion resistance, which is beneficial in industries like chemical processing, food processing, and pharmaceuticals. It can be used for manufacturing tanks, containers, and equipment that require resistance against harsh chemicals and environments. 7. Energy and sustainable applications: The lightweight nature and durability of coil-anodized aluminum make it suitable for energy and sustainable applications. It can be used in manufacturing solar panels, heat exchangers, and other energy-related components. The anodized coating provides protection against weathering and corrosion, ensuring long-term performance. Overall, the potential applications of coil-anodized aluminum coils are extensive and diverse, ranging from architectural and transportation to electronics, signage, furniture, industrial, and energy sectors. The unique combination of lightweight, durability, color stability, and corrosion resistance makes it a versatile material for various industries and applications.

- Q: Can aluminum coils be used in high-radiation environments?

- Yes, aluminum coils can be used in high-radiation environments. Aluminum has good radiation resistance and can withstand high levels of radiation without significant degradation or damage. It is commonly used in applications such as nuclear power plants and aerospace industries, where radiation exposure is a concern.

- Q: What are the main causes of aluminum strip rolling?

- Also, what types of mill, simple four roll or roll type control of CVC and HC mills?

- Q: What is a better deal?Aluminum Cookware ( Paula Deen)orHard Anodized ( Rachael Ray )

- Wow, Thank you! Exactly what I was searching for. I looked for the answer on other websites but I couldn't find them.

- Q: What is the typical hardness of aluminum coils?

- The typical hardness of aluminum coils can vary depending on the specific alloy and temper used, but generally falls within the range of 40-70 on the Rockwell B scale.

- Q: How are aluminum coils used in the production of automotive heat shields?

- Aluminum coils play a crucial role in the production of automotive heat shields. Heat shields are essential components in vehicles designed to protect various parts from excessive heat generated by the engine, exhaust system, or other heat sources. These shields are typically made from lightweight and heat-resistant materials, and aluminum coils are a popular choice due to their excellent thermal conductivity, durability, and corrosion resistance. In the production process, aluminum coils are first unwound and then cut into sheets of the desired size for the heat shields. These sheets are then formed into specific shapes using various techniques such as stamping, bending, or deep drawing. The ability of aluminum to be easily shaped and molded makes it ideal for creating heat shields with complex geometries, ensuring a precise fit in the vehicle. Once the desired shape is achieved, the aluminum sheets are often treated with a surface coating to enhance their heat resistance and protect against corrosion. This coating can be in the form of a ceramic or metallic layer, providing an additional barrier against extreme temperatures. The formed and coated aluminum sheets are then typically layered with other insulating materials, such as ceramic fibers or laminated films, to further enhance the heat shield's performance. These additional layers help to reduce heat transfer by reflecting or absorbing the heat energy, thereby protecting the surrounding components from potential damage or overheating. Finally, the assembled heat shields are mounted in specific locations within the vehicle, such as around the exhaust system or near the engine, using fasteners or adhesive techniques. The lightweight nature of aluminum coils ensures that the heat shields do not add unnecessary weight to the vehicle, which is crucial for maintaining fuel efficiency and overall performance. In conclusion, aluminum coils are used extensively in the production of automotive heat shields due to their excellent thermal conductivity, durability, and corrosion resistance. Their ability to be easily shaped and molded, combined with surface coatings and additional insulating layers, ensures effective heat insulation and protection for various vehicle components.

- Q: How to calculate the weight of strips with the weight of aluminum coil known?

- Thickness*width*length=weight/density, length=weight/(density*thickness*width).Ps: Keep unit the same.

- Q: Are aluminum coils suitable for HVAC ductwork?

- Yes, aluminum coils are suitable for HVAC ductwork. Aluminum coils are preferred for HVAC ductwork due to their lightweight and corrosion-resistant properties. They are highly durable and can withstand extreme temperatures and weather conditions. Additionally, aluminum coils have excellent thermal conductivity, which allows for efficient heat transfer and ensures optimal cooling or heating performance. Moreover, aluminum is a non-toxic material, making it safe for use in HVAC systems. Overall, aluminum coils are an ideal choice for HVAC ductwork, providing long-lasting performance and energy efficiency.

- Q: How do aluminum coils contribute to energy efficiency in buildings?

- Aluminum coils play a crucial role in enhancing energy efficiency in buildings. Firstly, aluminum is a highly conductive material, allowing for efficient heat transfer. This characteristic is essential in HVAC (Heating, Ventilation, and Air Conditioning) systems, where aluminum coils are commonly used. These coils facilitate the transfer of heat between the indoor and outdoor units, enabling effective temperature regulation and reducing energy consumption. Moreover, aluminum coils are lightweight, which makes them easier to handle and install. This not only saves time and labor costs but also reduces the overall weight of the HVAC system, leading to lower energy requirements for operation. Additionally, the lightweight nature of aluminum coils allows for the design of compact systems, saving valuable space in buildings. Furthermore, aluminum is highly resistant to corrosion, ensuring the longevity and durability of the coils. This resistance to corrosion is particularly crucial in areas with high humidity or exposure to harsh weather conditions. By maintaining their effectiveness over time, aluminum coils minimize the need for frequent replacements, reducing energy consumption associated with manufacturing and installation processes. Another significant benefit of aluminum coils is their recyclability. Aluminum is one of the most recycled materials globally, with a high recycling rate and minimal loss of quality during the process. By using aluminum coils, buildings contribute to a more sustainable and environmentally friendly approach, as the material can be recycled repeatedly without compromising its performance. Moreover, the recycling process requires significantly less energy compared to primary aluminum production, reducing greenhouse gas emissions. In conclusion, aluminum coils contribute to energy efficiency in buildings through their high conductivity, lightweight nature, corrosion resistance, and recyclability. By facilitating efficient heat transfer, reducing energy consumption, and promoting sustainability, aluminum coils play a vital role in enhancing the energy efficiency of HVAC systems and overall building performance.

- Q: How do aluminum coils compare to other non-ferrous metals like titanium?

- Aluminum coils are generally lighter, more affordable, and easier to work with compared to non-ferrous metals like titanium. However, titanium possesses superior strength, corrosion resistance, and heat resistance properties, making it a preferred choice for applications requiring high performance and durability.

Send your message to us

026 Aluminum Coil Hot Rolled Aluminium Circle AA3003 H14

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords