Hot Oil Circulation Pump with High Temperature

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Oil Circulation Pump for Food Industry

1.Structure of Hot Oil Circulation Pump Description

Hot Oil Circulation Pump is used in transporting high temperature liquid without solid particles.The temperature is not higher than 370 °C.This pump is proper in machinery manufacturing, food processing, medicine making and the circling system for oil supplying of the hot oil boiler, the circling system of the heating installation.

2.Main Features of the Hot Oil Circulation Pump

•Reached JB/JQ20104-1998 standards.

•Oil temperature can reach to 200degre.

•SS304 material

•Good quality

3.Hot Oil Circulation Pump images

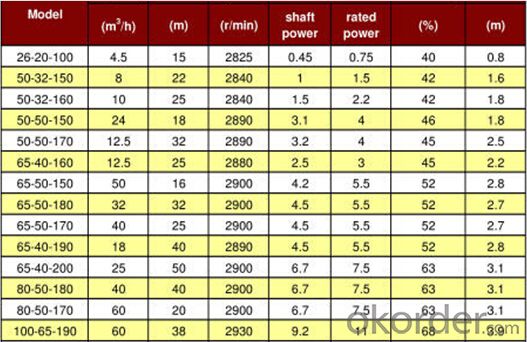

4.Hot Oil Circulation Pump Specification

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also

provide the pump model you are using now, price will be calculated as per the pump model, if not, we willrecommend relevant product for reference.

- Q: Working principle and diagram of axial piston pump with pressure compensation variable

- The size of the outlet flow pressure compensated variable displacement pump with outlet pressure of approximately in a certain range according to the constant power curve. When the pressure oil from the main part of the channel (a), (b), (c) into the inferior vena cava (d) variable shell, oil by the channel (E) respectively into the channel (f) and (H), when the spring force is greater than the oil (f) into the lower end of the piston ring servo hydraulic thrust area when the oil liquid (H) to the chamber (g), push the variable downward movement of the piston, the pump flow increases. As for the hydraulic servo piston end thrust force ring shaped area is greater than the spring when the servo piston moves upward, blocking channels (H), the (g) (I) through the cavity of the oil cavity pressure relief, at this time, the piston moves up, the variable head angle decreases, the pump flow rate decreases.

- Q: What is the name of the day pump and ground pump? Specific introduction

- PumpGround pumps are used very frequently in many large basements, because they have no boom, so they need to be taken over manually. In addition to the site, for those days to pump the high-rise buildings, such as 200 meters or 200 meters altitude, can also take over to transport concrete by pump, but the premise is to have enough power to pump concrete will hit above the height and the length of nozzle can reach the height of the floor.Thus, the day pump and ground pump have their respective advantages. The pump is easy to use, but the ground pump can make up for the height that the pump can not reach. At the same time, the price is relatively cheap, so users can choose the corresponding concrete pump when they are in use.

- Q: What is double hydraulic pump?

- [double hydraulic pump] the same drive shaft drives the rotation of two pumps, which are connected together and driven by an electric motor. The suction port of the pump is common, and the oil pressure port is separated from each other. Pump output of two shares of flow can be used alone, can also be used in parallel. This pump, a pump can play the function of two pumps. For example, there are two pumps on the loader, a pump acting as the work, a pump acting as the steering, and the double linked pump can replace the functions of the two pumps. It works by coupling the two pumps at the same time.

- Q: What is the relationship between the minimum suction vacuum of a pump and the required cavitation?

- When the pump is working, the liquid at the inlet of the impeller, due to a certain vacuum pressure will produce steam, the vaporization of the bubble in liquid particles under the impact of movement, the impeller and other metal surface erosion, thereby damaging the impeller and other metal

- Q: Why can the centrifugal pump hold down the pressure?

- The pump before starting to pump shell and the water pipe filled with water, and then start the motor, the pump shaft to drive the impeller and water do high-speed rotation, centrifugal water movement, was thrown to the outer edge of the impeller, the pressure water pipeline flow through the volute pump into the pump shell.

- Q: Does the reservoir water heater press the booster pump (high marks)?

- The outlet water pressure of hot water is the same as that of cold water. The water heater is pushed by cold water to push out the hot water. (of heating). Installation location about 2 meters away from the ground, the impact of water pressure is not large, in rural areas, the installation position in more than two buildings will have an impact. In the city, the installation position is above four floor to affect the water pressure.

- Q: How many square cables does the submersible pump for 7.5KW need?

- 7.5KW's submersible pump requires 2.5 square aluminum cables.Calculate the current value of submersible pump first:

- Q: Types and differences of pumps

- (I) volumetric typeClassification reciprocating rotary typeThe basic principle of reciprocating action by the piston in the cylinder in the cylinder volume changes again, with the suction and discharge of fluid in the shell or the rotor rotating member rotates, the volume of work between rotor and casing changes to the suction and discharge fluid, such as piston pump gear pump, screw pump(two) blade type;The main structure of vane pumps and fans is rotary, bladed impellers and stationary housings that rotate fluid through the impeller to do work, thereby enabling fluids to obtain energy

- Q: What is a vacuum pump for?

- You are not confused by different names. It is mainly used in folding machines, paper cutting machines and water treatment aeration

- Q: Why does the centrifugal pump start with a closed valve and the axial pump starts with an opening valve?

- Because the characteristic curves of the two are different.The power of centrifugal pump decreases with the decrease of flow rate. When the flow rate is zero, the power is minimum, so the centrifugal pump is started with a closed valve.

Send your message to us

Hot Oil Circulation Pump with High Temperature

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords