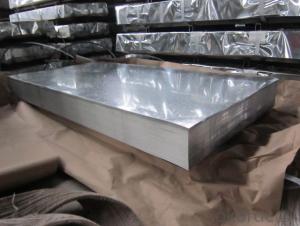

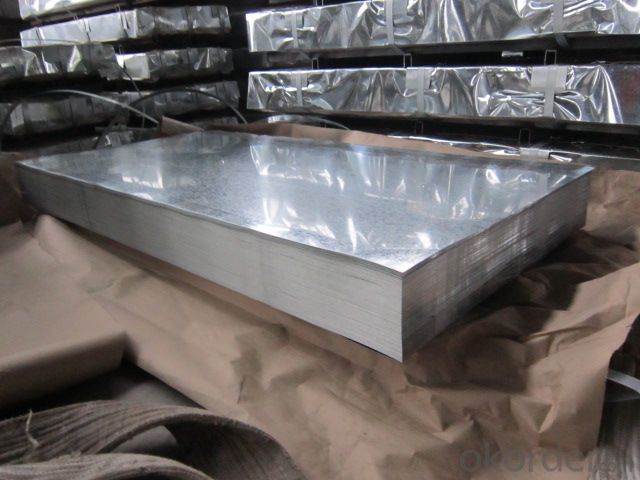

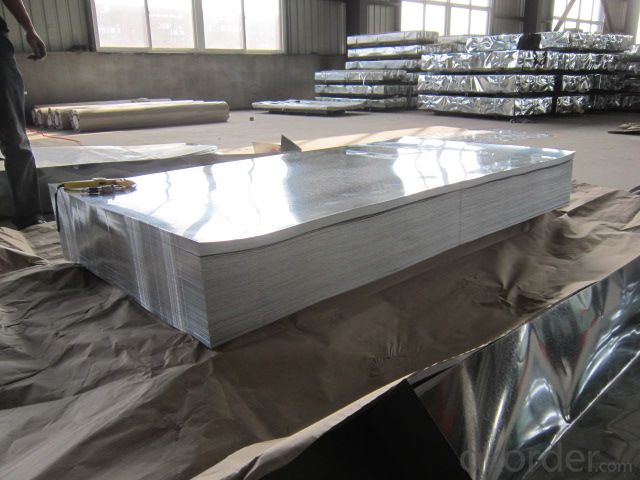

Hot-dipped-Galvanized Steel Sheet in Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

The most external layer is all zinc, but successive layers are a mixture of zinc and iron, with an interior of pure steel. These multiple layers are responsible for the amazing property of the metal to withstand corrosion-inducing circumstances. Zinc also protects the steel by acting as a "sacrificial layer." If rust does take hold on the surface of Galvanized Steel Coil, the zinc will get corroded first. This allows the zinc that is spread over the breach or scratch to prevent rust from reaching the steel.

Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds.

1. Good Resistance to Corrosion

2. Qualified Processing Machinability

3. High Thermal Resistance

4. Excellent Reflectivity

Application:

Construction, packaging, railway vehicles, agricultural machinery and daily life.

Oiled/dry, Skin-pass/Nonskin-pass, Regular/Minimize/Zero Spangle

For countless outdoor, marine, or industrial applications, Galvanized Steel Coil is an essential fabrication component.

Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds.

Appliances Industry Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts.

Product Specification:

Base sheet : galvanized steel sheet, pre painted galvanized steel sheet

Zinc:40G-275G

Thickness:0.12mm-3.2mm

Width:600mm-1500mm

Length:1000mm-11800mm or as request

Package:Standard seaworthy export packing: 3 layers of packing, inside is kraft paper,water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock.

FAQ:

1.How many pieces for one ton of the Hot-dip Galvanized Steel Sheet?

The pieces for one tone is decided by the thickness of the sheet, but we can make it according to your requirements in the reasonable range.

2. Do you have pallets for the package?

Yes, we must use pallets for the package in order to load.

3. How many tons do you load in one 20’FCL?

- Q: Can steel sheets be used in marine applications?

- Yes, steel sheets can be used in marine applications. Steel is a common material used for constructing ships, offshore platforms, and other marine structures due to its high strength, durability, and resistance to corrosion in saltwater environments.

- Q: Can steel sheets be used for staircase railings?

- Yes, steel sheets can be used for staircase railings. Steel is a durable and strong material that is commonly used in construction and engineering applications. Steel sheets can be fabricated into various shapes and designs to create stylish and modern staircase railings. They can be easily customized to suit different architectural styles and preferences. Additionally, steel railings are known for their longevity and low maintenance requirements, making them a popular choice for staircase installations.

- Q: What is the difference between a matte and glossy steel sheet?

- The main difference between a matte and glossy steel sheet lies in their surface finish. A matte steel sheet has a dull, non-reflective surface that diffuses light, resulting in a more muted appearance. On the other hand, a glossy steel sheet has a smooth, reflective surface that reflects light, giving it a shiny and polished look.

- Q: How do steel sheets perform in electrical conductivity?

- Steel sheets have low electrical conductivity compared to other metals such as copper or aluminum. This is because steel is primarily composed of iron, which is a poor conductor of electricity. However, the electrical conductivity of steel can be improved by adding certain alloying elements or through specialized treatments.

- Q: Are the steel sheets resistant to chemical spills?

- Yes, steel sheets are generally resistant to chemical spills due to their inherent corrosion resistance properties.

- Q: How do steel sheets perform in abrasive environments?

- Steel sheets perform well in abrasive environments due to their high strength and durability. The hardness of steel allows it to resist the wear and tear caused by abrasive materials, such as sand, gravel, or dust particles. Additionally, the smooth surface of steel sheets helps to reduce friction and prevent the accumulation of debris, further enhancing their performance in abrasive environments. Steel sheets can withstand the impact of abrasive materials without deformation or damage, making them ideal for applications such as construction, mining, and manufacturing industries. However, it is important to note that certain types of steel, such as stainless steel, are more resistant to corrosion and rust, which can also be factors in abrasive environments. Regular maintenance and protective coatings can further enhance the performance and longevity of steel sheets in abrasive environments.

- Q: What are the different surface coatings available for steel sheets?

- There are several different surface coatings available for steel sheets, including galvanized coatings, zinc coatings, tin coatings, and paint coatings.

- Q: What is AO steel plate?

- The locking plate is fixed to connect without bone friction, but rely entirely on the steel plate interlocking structure to achieve. The steel plate and the bone surface can leave the gap, to eliminate the adverse effects of contact with bone plate stress, greatly improve the blood supply and the growth of periosteum and recovery. Screw and plate angle fixed, plate and screw and the backbone form the stereo than ordinary AO plate fixation, locking plate fixation is more stable.

- Q: Can steel sheets be used for bridge construction?

- Yes, steel sheets can be used for bridge construction. Steel is a commonly used material in bridge building due to its strength, durability, and resistance to corrosion. Steel sheets are often used to fabricate the structural components of bridges, such as beams, girders, and decks, providing stability and reliability to the overall structure.

- Q: How do you calculate the weight of a steel sheet?

- The weight of a steel sheet can be calculated by multiplying the length, width, and thickness of the sheet, and then multiplying that result by the density of steel.

Send your message to us

Hot-dipped-Galvanized Steel Sheet in Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords