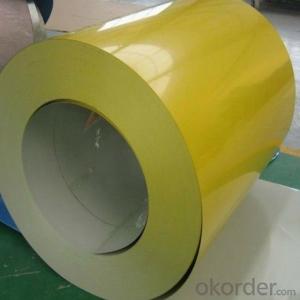

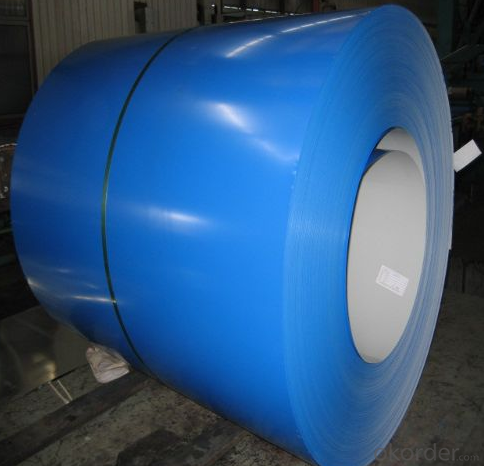

Color Coated Galvanized Steel Coils/Sheets from China CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Color Coated Steel Sheet at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Color Coated Steel Sheet is ideal for general fabricating and metalworking.

Product Advantages:

OKorder's Steel Sheet is durable, resists corrosion, and are conducive to processing, such as PPGI embossing, printing, and punching.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-30 days after receiving deposit)

· Corrosion resistance

· Professional Service

· Competitive pricing

Product Specifications:

Grade: Q195, SGCC, SGCD, SECC, SECD, DX51D+Z

Height: 90 – 400mm

Width: 600 – 1250mm

Thickness: 0.16 – 2.0mm

Length: As per customer request

Coating: 80 – 275g/m² Zn

Surface: Galvanized, zero spangle, regular spangle, normal spangle

Treatment: Chromated & oiled, chromated, non-oiled

Packaging: Standard export packing, 4 steel eye bands and 4 steel circumferential bands, galvanized metal fluted rings on inner and outer edges, galvanized metal and waterproof paper wall protection disk

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How are steel coils processed for slitting or edge trimming?

- Steel coils are processed for slitting or edge trimming by first being unwound from the coil and passed through a series of rollers to ensure a smooth and uniform surface. The coil is then cut into narrower strips using a slitting machine or trimmed along the edges to remove any imperfections or excess material. This process helps create precise and customized steel strips that can be used for various applications.

- Q: What are the common applications of cold-rolled steel coils?

- Cold-rolled steel coils have a wide range of common applications in various industries due to their exceptional qualities. One of the most common applications is in the automotive industry, where cold-rolled steel coils are used to manufacture car parts such as body panels, chassis components, and structural reinforcements. The high strength and excellent formability of cold-rolled steel make it ideal for these applications. Another common application is in the construction industry, where cold-rolled steel coils are used to fabricate structural elements for buildings and infrastructure. Cold-rolled steel is often used to make beams, columns, and other load-bearing components due to its superior strength and durability. Cold-rolled steel coils are also widely used in the manufacturing of appliances and consumer goods. They are commonly used to create the outer shells of refrigerators, washing machines, and ovens. The smooth and consistent surface finish of cold-rolled steel makes it perfect for these applications, as it provides an aesthetically pleasing appearance. Additionally, cold-rolled steel coils find applications in the electrical industry. They are used to produce electrical enclosures, transformers, and various other components due to their excellent electrical conductivity and magnetic properties. Overall, the common applications of cold-rolled steel coils span multiple industries, including automotive, construction, appliances, and electrical. The versatility, strength, formability, and aesthetic appeal of cold-rolled steel make it a preferred choice for many manufacturers in various sectors.

- Q: I want to build an indoor riding arena, should I go for Steel ones.

- Though okorder /.. You can also have a look!!

- Q: What is the minimum order quantity for steel coils?

- The minimum order quantity for steel coils can vary depending on the supplier and specific product. It is recommended to contact the supplier directly to inquire about their minimum order requirements for steel coils.

- Q: Can steel coils be used in the production of consumer goods?

- Yes, steel coils can be used in the production of consumer goods. Steel coils are typically used as raw material in various industries, including automotive, construction, and manufacturing. In the consumer goods industry, steel coils can be used to produce a wide range of products such as appliances, furniture, tools, packaging materials, and even consumer electronics. The inherent strength, durability, and versatility of steel make it an ideal choice for manufacturing consumer goods that require stability, safety, and longevity. Additionally, steel coils can be easily shaped, molded, and formed into different components or parts, allowing for customization and design flexibility in the production process. Therefore, steel coils play a crucial role in the production of consumer goods and are widely used across various sectors.

- Q: which type of carbon steel does not have manganese

- None. Mn is a trace impurity in all steels, if you look carefully enough. If you want to find a steel where Mn is not intentionally added, start looking at the alloy composition specifications, there are hundreds of steels. Why are you worried about Mn? Mn is typically added to steels for a very good reason.

- Q: How are defects in steel coils repaired?

- Defects in steel coils can be repaired through several methods depending on the type and extent of the defect. One common approach is known as welding repair, which involves using specialized welding techniques to fix the defect. This method is typically used for minor defects such as cracks or small holes in the coil. The damaged area is cleaned, prepped, and then welded using appropriate welding rods or wires to ensure a strong and durable repair. For more severe defects, such as large holes or significant damage to the coil, a patching technique may be employed. This involves cutting out the damaged section and replacing it with a new piece of steel. The patch is usually welded to the intact areas of the coil, ensuring a secure and seamless repair. In some cases, defects can also be addressed through grinding or sanding techniques. This is often used for surface defects like scratches or blemishes that do not compromise the structural integrity of the coil. Grinding or sanding the affected area smooths out the defect, improving the appearance and preventing further damage. It is worth noting that the repair method chosen depends on factors such as the specific defect, the material of the coil, and the intended application of the steel. The repair process may also involve additional steps such as heat treatment or surface finishing to restore the coil to its original condition. Overall, repairing defects in steel coils requires the expertise of skilled technicians and specialized equipment. It is crucial to address these defects promptly to prevent further damage and ensure the coil's performance and longevity.

- Q: How are steel coils used in the production of metal buildings?

- Steel coils are used in the production of metal buildings as they are rolled into sheets and then formed into various structural components such as beams, columns, and roof panels. These coils allow for efficient mass production and provide a high-strength and durable material that ensures the structural integrity of the metal building.

- Q: What are the different types of steel grades used for coil production?

- There are various types of steel grades used for coil production, including carbon steel, stainless steel, high-strength low-alloy (HSLA) steel, and advanced high-strength steel (AHSS). Each grade has its own unique properties and is chosen based on the specific requirements of the application.

- Q: What are the common sizes of steel coils?

- The common sizes of steel coils vary depending on the specific application and industry. However, some standard sizes for steel coils include widths ranging from 0.5 inches to 72 inches, and thicknesses ranging from 0.010 inches to 0.250 inches. These sizes can be customized to meet the specific requirements of different industries such as automotive, construction, or manufacturing.

Send your message to us

Color Coated Galvanized Steel Coils/Sheets from China CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords