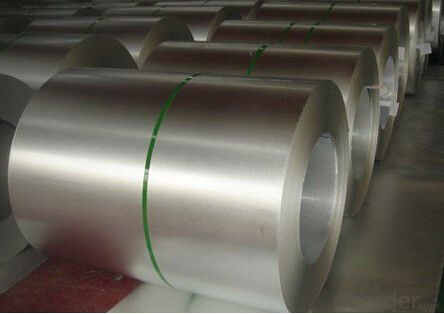

Hot Dipped Galvanized Steel Coil (DC53D+Z, St05Z, DC53D+ZF)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Info.

Model NO.:DC53D+Z, St05Z, DC53D+ZF

Surface Treatment:Galvanized

Technique:Cold Rolled

Standard:ASTM, JIS, GB, AISI, DIN, BS

Steel Grade:DC53D+Z, St05z, DC53D+Zf

Commodity Name:Hot Dipped Galvanized Steel Coil

Thickness:0.3-3.0mm

Width:800-1830mm

Zinc Coating:40-275g

Export Markets:Global

Additional Info.

Trademark:Helio

Packing:Inside: Moisture-Proof Paper/Outside: Steel Plate

Standard:AS buyer requirement

Origin:China

Production Capacity:5000tons Per Month

Product Description

Hot Dipped Galvanized Steel Coil

Hot Dipped Galvanized Steel Coil (DC53D+Z, St05Z, DC53D+ZF)

Brief Introduction:

Commodity name : Hot Dipped Galvanized Steel Coil

Standard we can provide: AISI ASTM BS DIN GB JIS

Grade : DC53D+Z,St05Z,DC53D+ZF

Zinc Coating:40g-275g/m2

Size we can provide:

Size Range: CRC substrate Thickness: 0.3-3.0mm

CRC substrate Width: 800-1830mm

HRC substrate Thickness:1.8-2.8mm

HRC substrate Width:900-1500mm

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q: What are they worth today? As well as a 1943 steel nickel?

- I think they are worth about a pennie.

- Q: Can steel coils be customized in terms of size and shape?

- Yes, steel coils can be customized in terms of size and shape. They can be manufactured to specific dimensions and configurations according to the requirements and specifications of the customer.

- Q: I am doing a project on how revolvers work and what materials they use and would like to know what specific grade of stainless steel they use for the manufacturing of the frame and cylinder?

- *Rifle barrels are usually made from steel alloys called ordinance steel, nickel steel, chrome-molybdenum steel, or stainless steel, depending upon the requirements of the cartridge for which they are chambered. The higher the pressure and velocity of a cartridge (pressure and velocity usually go up together), the faster it will wear out a barrel. To give a satisfactory service life, barrels for high velocity cartridges must me made from tougher and harder steel than barrels for lower pressure cartridges. *The 400 (416) series SS commonly known as ordnance grade , is what barrels are made from . *If you want your barrel to be made from super alloy then it is 718 Inconel ,but a costly affair.

- Q: How are steel coils used in the manufacturing of agricultural machinery?

- Steel coils are used in the manufacturing of agricultural machinery as they are shaped and cut to create various components such as frames, brackets, and structural supports. These coils provide the necessary strength and durability required for heavy-duty equipment used in farming operations.

- Q: How are steel coils used in the production of railway tracks?

- Steel coils are a crucial component in the production of railway tracks. These coils are typically made of high-quality steel and are used to manufacture the rails that form the foundation of the tracks. The process begins with the steel coils being unwound and fed through a series of machines that shape and form them into the desired rail profile. The steel coils are first passed through a rolling mill, where they are gradually flattened and shaped into long strips of steel. This process is known as hot rolling, as the steel is heated to high temperatures to make it more malleable. The rolling mill applies immense pressure to the steel, gradually transforming it into the desired rail shape. Once the steel coils have been rolled into the required shape, they are then cut into individual rail lengths. These lengths can vary depending on the specifications of the railway track being produced. The rail lengths are then further processed to remove any imperfections and straighten them out. After this initial shaping and processing, the rails are subjected to a series of additional treatments. These treatments may include heat treatment to enhance their strength and durability, as well as various surface treatments to prevent corrosion and wear. Once the rails have undergone all the necessary treatments, they are ready to be installed on the railway track. They are laid out in a carefully planned pattern, with each rail securely fastened to the sleepers or ties. The continuous length of steel provided by the coils ensures a seamless and uniform track, allowing trains to travel smoothly and safely. In summary, steel coils play a vital role in the production of railway tracks. They are used to manufacture the rails that form the foundation of the tracks, ensuring durability, strength, and a smooth surface for trains to run on. The use of high-quality steel coils in this process is essential to ensure the safety and efficiency of railway transportation.

- Q: What are the different methods of forming steel coils?

- Steel coils can be formed using several methods, depending on their specific requirements and applications. These methods comprise hot rolling, cold rolling, and continuous casting. The most commonly used method for forming steel coils is hot rolling. This involves heating the steel billet or ingot to high temperatures and passing it between a series of rollers to reduce its thickness and shape it into a coil. Typically, this process is carried out above the recrystallization temperature of the steel, which allows for better shaping and improved mechanical properties. On the other hand, cold rolling is performed at or near room temperature. It entails passing the steel through a series of rollers to reduce its thickness and shape it into a coil. Cold rolling is often utilized to produce steel coils with precise dimensions and excellent surface finish. Additionally, it can enhance the strength and hardness of the steel. Another method for forming steel coils is continuous casting. This involves pouring molten steel into a continuous casting machine, where it solidifies into a strand. The strand is then continuously fed into a series of rollers, which shape it into a coil. Continuous casting offers several advantages, including improved efficiency, reduced energy consumption, and better control over the steel's composition and quality. In addition to these primary methods, there are various secondary processes involved in forming steel coils. These processes encompass pickling, annealing, and coating. Pickling is used to remove any rust or scale from the surface of the steel, ensuring a clean and smooth finish. Annealing involves heating the steel to a specific temperature and then slowly cooling it, which improves its ductility and reduces internal stresses. Coating is often applied to steel coils to provide corrosion resistance or enhance its aesthetic appeal. To summarize, steel coils can be formed using different methods such as hot rolling, cold rolling, and continuous casting. Each method offers distinct advantages and is chosen based on the specific requirements of the steel product. Additionally, secondary processes like pickling, annealing, and coating are employed to further enhance the quality and performance of the steel coils.

- Q: I was curious to what type of steel I should get if I wanted something that kept its edge longer than 154cm but is still just as stainless. I don't know much about knife steels inform me please?

- If you want a good quality knife, stay away from Stainless, I would suggest one that is a mix of high and low carbon steel, high carbon holds the edge, but is brittle, low carbon is more malleable, which prevents from breaking when used.

- Q: How are steel coils used in the manufacturing of wires?

- Steel coils are used in the manufacturing of wires by being fed into wire drawing machines, where they are gradually reduced in diameter through a series of dies. The steel coils serve as the initial raw material, providing the necessary strength and flexibility for the wires to be produced.

- Q: I know there is soft steel and sturdier steel they use in products. The sturdier often used for equipment that requires more durability when in operation.

- harder steel has a higher carbon and chromium content

- Q: How do steel coil manufacturers manage inventory?

- Steel coil manufacturers employ a variety of strategies and techniques to effectively manage their inventory, optimize production, minimize costs, and meet customer demands. The following are some commonly used practices: 1. Accurate demand forecasting: Steel coil manufacturers analyze market trends, historical sales data, and customer orders to accurately forecast future demand. This enables them to determine the necessary inventory levels and plan production accordingly. 2. Just-in-time (JIT) inventory: Many steel coil manufacturers adopt the JIT inventory system, which involves maintaining minimal inventory levels by receiving raw materials shortly before production and delivering finished goods immediately after. This approach reduces carrying costs and mitigates the risk of excess inventory. 3. Collaborating with suppliers: Effective inventory management relies on close collaboration with suppliers. Steel coil manufacturers work closely with their suppliers to ensure timely delivery of raw materials, monitor quality, and maintain a consistent supply. Regular communication and sharing of production forecasts help suppliers plan their inventory accordingly. 4. Safety stock: Steel coil manufacturers maintain a certain level of safety stock to account for unpredictable fluctuations in demand, disruptions in the supply chain, or delays in raw material deliveries. This acts as a buffer to prevent stockouts and maintain customer satisfaction. 5. Implementing inventory control systems: Steel coil manufacturers utilize modern inventory control systems, such as Enterprise Resource Planning (ERP) software, to track inventory levels, monitor stock movements, and automate various inventory management processes. These systems provide real-time data and analytics, facilitating better decision-making and improving inventory accuracy. 6. Streamlining production planning: Steel coil manufacturers optimize production planning to minimize inventory holding costs. They schedule production based on demand forecasts, prioritize orders, and strive for efficient production runs to reduce setup times and material waste. 7. Regular inventory analysis: Steel coil manufacturers regularly analyze their inventory data to identify slow-moving items, obsolete stock, or excess inventory. By identifying such issues, they can take corrective actions such as offering discounts, initiating sales promotions, or adjusting production schedules to prevent inventory buildup. In conclusion, effective inventory management is crucial for steel coil manufacturers to maintain a lean and efficient operation while meeting customer demands. By utilizing these strategies, manufacturers can strike a balance between supply and demand, reduce costs, and enhance customer satisfaction.

Send your message to us

Hot Dipped Galvanized Steel Coil (DC53D+Z, St05Z, DC53D+ZF)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords