Hot DIP Galvanized Steels in Coil (HDGI)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.:SGCC/ASTM/EN

Standard:ASTM, JIS, GB, AISI, DIN, BS

Steel Grade:Q350/Q550

Certification:SGS

Surface Treatment:Galvanized

Technique:Cold Rolled

Application:Ship Plate

Edge:Slit edge

Stock:Stock

Spangle:No/ Small/ Regular /Big Spangle

Commodity:Hot DIP Galvanized Steel Coil (Gi)

Width:914/1000/1200/1219/1200/1220/1250mmetc

Thickness:0.12-1.2mm

Zinc-Coating:Z60, Z80, Z100, Z120, 150 etc

Surface Treament:Passivation, Dry/ Oiled/ Skinpassed

Export Markets:Global

Additional Info.

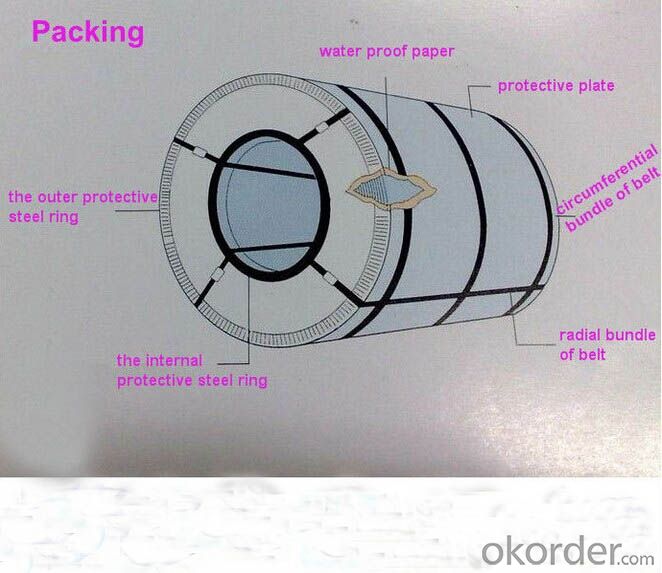

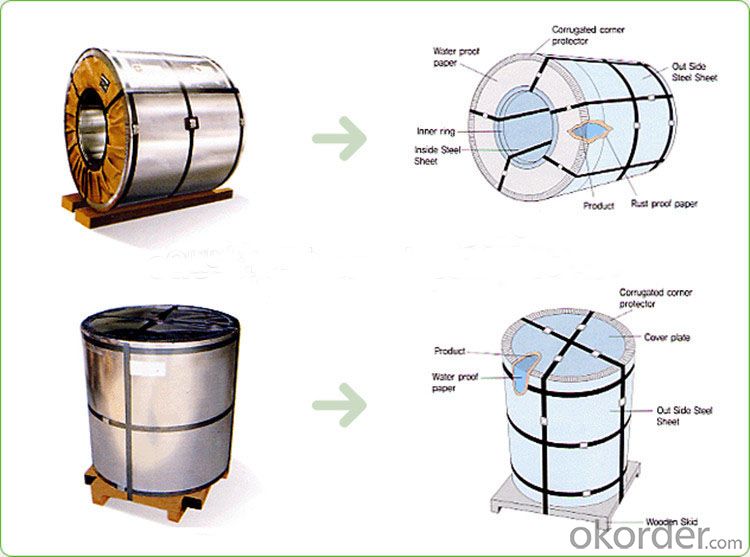

Packing:Standard Export Seaworthy Packing

Standard:0.14-1.2*600-1250mm

Origin:China

HS Code:72104900

Production Capacity:4000 Tons Per Month

Product Description

Hot DIP Galvanized Steel in Coil (GI)

1. Techinical: EN10143, ASTM A653, JIS3302

2. Grade: DX51D, SGCC, commercial quality

3. Thickness: 0.14-0.5mm( the most advantage thickness)

4. Width: 600-1250mm(726, 914, 1000, 1200, 1220, 1250mm)

5. Spangle: No spangle, small spangle, regular spangle

6. Surface treament: Oiled/ dry; Chromed passivation/ anti-finger print; Skinpassed

7. Zinc-coating: Z40-150G/M2

0.18-0.8mm Special Color Galvanized Steel Coil

1. Techinical standard: EN10169

2. Grade: TDX51D, TSGCC

3. Thickness: 0.14-0.8mm (the most advantage thickness)

4. Width: 600-1250mm (610/724/820/914/1000/1200/1219/1220/1250)

5. Base metal: Galvanized / galvalume steel

6. Finish Painting: 15-20miu PE on top

Back painting: 5-8miu EP on back

7. Type of PPGI PPGI with pattern

Specifications:

1. Standard: AISI, ASTM, BS, DIN, GB, JIS, ASTM, JIS, GB

2. Steel Grade: DX51D, SGCC, SGCH, SPCC, SPCD, DC01, ST12, ST13, Q195, 08AL

3. Thickness: 0.13-0.5mm

4. Width: 600-1250mm

5. Length: Up to The Thickness or as require

6. Spangle: Zero, Mini, Regular, Big, Skin Pass

7. Audited Certificates: BV, SGS, ISO, CIQ

8. Zinc Coating: 40g-200g

9. Surface: Chromated, dry/oiled, Cr3 treated anti-finger

10. Package: Standard exporting package (or as required)

11. ID: 508/610mm

| Commodity | Hot dip galvanized steel coil and sheet (GI) |

| Techinical Standard: | JIS 3302 / ASTM A653 / EN10143 |

| Grade | DX51D / DX52D/ DX53D/ S250, 280, 320GD |

| Types: | Commercial / Drawing / Deep Drawing / Structural quality |

| Width | 650/726/820/914/1000/1200/1219/1220/1250mm |

| Thickness | 0.12-1.0mm (0.14-0.5mm is the most advantage thickness) |

| Type of coating: | galvanized |

| Zinc coating | Z60-150g/m2 |

| Surface treament | chromed / skinpass/ oiled/slightly oiled/ dry/ anti-fingerprint |

| Surface structure: | zero spangle / minimized spangle / regular spangle/ big spangle |

| ID coil | 508mm or 610mm |

| Coil weight | 3-6 MT per coil |

| Package: | Properly packed for ocean freight exportation in 20' ' containers |

| Application: | Industrial panels, roofing and siding for painting |

| Price terms | FOB, CFR, CIF |

| Payment terms | 20%TT in advance+80% TT or irrevocable 80%L/C at sight |

| delivery time | 25 days after recepit of 20% TT |

| Remarks | Insurance is all risks |

| MTC 3.1 will be handed on with shipping documents | |

| We accept SGS certificatation test |

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

Package:

- Q: Does anyone know the lyrics to steel driving man by Dailey and Vincent. I would really appreciate it

- watch man of steel full movie online free adf.ly/dfxYD

- Q: How are steel coils used in the manufacturing of building materials?

- Steel coils are widely used in the manufacturing of building materials due to their strength, durability, and versatility. These coils are typically made from high-quality steel and are shaped into a continuous, flat strip. One of the most common uses of steel coils in building materials is for the production of steel roofing and siding. The coils are processed through a series of machines that cut, shape, and roll the steel into the desired dimensions and profiles. The resulting roofing and siding materials are then used to construct durable and weather-resistant building envelopes. Steel coils are also used in the manufacturing of steel studs, which are essential components for framing structures. The coils are cut and formed into precise shapes, then assembled to create a strong and rigid framework for walls, ceilings, and other structural elements. Steel studs offer numerous advantages such as high strength-to-weight ratio, fire resistance, and dimensional stability, making them a popular choice in the construction industry. In addition to roofing, siding, and framing, steel coils are utilized in the production of various other building materials. These include steel pipes, beams, columns, and reinforcement bars, which are used in the construction of foundations, infrastructure, and structural elements. Steel coils also serve as raw materials for the fabrication of metal panels, doors, windows, and other architectural components. Overall, steel coils play a crucial role in the manufacturing of building materials as they provide the necessary strength and durability required for long-lasting and robust structures. Their versatility allows for the production of a wide range of building components, making steel coils an indispensable resource in the construction industry.

- Q: How are steel coils inspected for thickness and width accuracy?

- Steel coils are inspected for thickness and width accuracy using various methods. One common method is using non-contact laser or ultrasonic sensors that scan the surface of the coil to measure its thickness and width. These sensors provide accurate measurements without physically touching the coil. Additionally, manual measurements can be taken using calipers or micrometers to verify the accuracy of the coil's dimensions. Overall, a combination of non-contact sensors and manual measurements ensure that steel coils meet the required thickness and width specifications.

- Q: What are the dimensions of steel coils used in the agricultural structure industry?

- The dimensions of steel coils used in the agricultural structure industry can vary depending on the specific application and requirements. However, common dimensions range from 0.5mm to 3mm in thickness and 600mm to 1500mm in width.

- Q: What is the average width tolerance for steel coils?

- The average width tolerance for steel coils can vary depending on the specific industry and application. However, in general, the standard width tolerance for steel coils is typically around ±0.005 to ±0.020 inches.

- Q: How are steel coils inspected for width?

- To ensure compliance with the necessary specifications, various techniques are employed to inspect the width of steel coils. Among these methods, a commonly used one is the utilization of a caliper gauge, also referred to as a micrometer. This gauge makes direct contact with the coil edges to measure its width. The operator places the gauge at multiple points along the width and records the measurements. This approach guarantees precise measurements and facilitates the identification of any inconsistencies or deviations in the desired width. Another technique employed for width inspection is laser measurement. In this method, laser sensors are positioned on both sides of the coil, emitting a laser beam that scans across the width. By detecting the distance between the edges of the coil, the sensors provide accurate width measurements. This non-contact approach is highly efficient, swiftly inspecting the coil's width without causing any physical damage or requiring physical contact. Moreover, advanced systems employ computer vision technology for width inspection. This involves the use of cameras and image processing software to capture images of the coil's edges. The software then analyzes these images and calculates the width based on the detected edges. This method enables rapid inspections and can identify any irregularities in the coil's width. In conclusion, the inspection of steel coil width involves a combination of physical gauges, laser sensors, and computer vision technology. These methods ensure that the coils conform to the required width specifications and play a crucial role in maintaining quality control throughout the steel manufacturing process.

- Q: Can steel coils be embossed?

- Yes, steel coils can be embossed. Embossing is a process that involves creating raised or indented patterns on a surface, and it can be done on various materials including steel coils. This technique is often used to enhance the aesthetic appeal or provide functional properties to the steel coils.

- Q: What is the market demand for steel coils?

- The market demand for steel coils varies based on several factors such as industry requirements, economic conditions, and global trade patterns. However, steel coils have a significant demand across various sectors including construction, automotive, manufacturing, and infrastructure development. The demand for steel coils is driven by their versatility, strength, and durability, making them a crucial component in various applications.

- Q: Why are steel saucepans and tea kettles covered with copper on the outside and the bottom? what r the goals of having high-quality pans that are thick and tea kettles that are thin walled?

- Stainless steel is less conductive than copper. However, steel will retain heat longer and thus be distributed more evenly. (hence the thick bottoms, but also for balance). Copper on tea kettles is ideal to bring water up to a boil rapidly but since your not really cooking food, temperature distribution or control doesn't really matter. Now if your cooking sensitive food, then it does matter. For example, the use of a double boiler is preferred for chocolates. Temperature and distribution is critical. As far as relatively inexpensive copper clad pots and pans such as Revereware? Well, I don't see a difference but perhaps they did some testing.

- Q: I've heard different things bout them, though I do not know this. Oh, and if you know where you can buy some raw or get custom made stuff out of black steel please let me know it would be greatly appreciated. Oh and my friend told me there is a black steel that can be sharpened and silver will be underneath, is this also true? Thank you very much for answering ^^

- black steel and black tron are not same.

Send your message to us

Hot DIP Galvanized Steels in Coil (HDGI)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords