Galvalume Hot Dip Galvanized Steel Sheet in Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

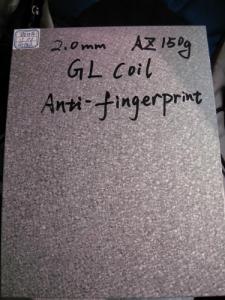

Galvalume Steel Sheet in Coils with Prime Quality and Best Price

Product Description:

Structure:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct

Main Features:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

- Q: How are steel coils secured during transportation?

- Steel coils are typically secured during transportation using steel strapping, bands, or wire rope. These securements help prevent the coils from shifting or falling off the transportation vehicle, ensuring their safe delivery to the destination.

- Q: Brass as a rule I believe is betterhowever I do not plan to get into reloading any time soon I just want some cheap practice ammo so will steel case ammo hurt my gun (semi auto) any more than brass ammo and if so how much more?

- If it's new you want to use quality brass ammo the first few hundred rounds. After that it doesn't matter. But do not you cannot use brass and steel in the same session. The lacquer tends to stay behind in the chamber, will fuse with the brass and you get torn case heads. So when using steel always only use steel that session and scrub the chamber down.

- Q: What are the different coil leveling line configurations used for steel coils?

- There are several different coil leveling line configurations used for steel coils, including the single leveler line, the double leveler line, and the tandem leveler line. Each configuration offers unique advantages and is suited for specific coil leveling requirements. The single leveler line is the simplest configuration, featuring a single leveling machine that removes coil deformations. The double leveler line utilizes two leveling machines in tandem, allowing for improved flatness and surface quality. The tandem leveler line consists of multiple leveling machines in series, offering the highest level of flatness and precision. These different configurations cater to varying coil thicknesses, widths, and production demands, providing flexibility and efficiency in steel coil processing.

- Q: I want to anodize steel using heat. some steel turns gray instead of coloring when I heat it up using a torch.

- Steel doesn't anodize in the sense that aluminum and some other metals do. However, it can be heat-colored. The trick is to clean the surface first (it must be oxide free), then heat gently until the colors appear. These are called temper colors in steel. They are due to a thin adherent layer of oxide that forms and thickens as temperature is increased. They are quite temperature dependent. As the steel is heated, the first color to appear is pale yellow. This will progress through darker yellows, browns, purples, and blues as the temperature rises. Above blue, the oxide becomes the gray/black color you are apparently getting - this is the result of heating too fast and too hot. See the chart at the site below for colors in plain carbon steel. Note that the temperatures are pretty low - It all starts around 400 F and if you go above 600 F the show's all over.

- Q: What kind of steel should be used for constructing a steel building?

- Please specify what kind of steel, is it structural steel (like wide flange, channel or Z-section) or reinforcing steel? For structural steel, all steel members that passed the requirement of ASTM-A360 are the best quality. While for reinforcing steel, it should passed the requirement of ASTM-D3963 for epoxy coated and ASTM-A615 (Grade 60) for deformed bars.

- Q: How are steel coils used in the production of oil and gas pipelines?

- Steel coils are used in the production of oil and gas pipelines as they are formed into pipes and provide the necessary strength and durability required for transporting these resources over long distances. The coils are uncoiled and then shaped into pipes through a process called pipe forming or rolling, which allows for the creation of seamless or welded pipes depending on the specific requirements. These pipes are then further processed, such as being welded together, coated, or threaded, to ensure their suitability for the transmission of oil and gas. Overall, steel coils play a crucial role in the manufacturing of pipelines by providing the necessary raw material for their construction.

- Q: Can steel coils be coated with color-changing materials?

- Yes, steel coils can be coated with color-changing materials. These materials are typically applied as a topcoat or overcoat on the steel surface, allowing the coils to exhibit different colors or hues based on external factors such as temperature, light, or chemical reactions. This coating technology can provide visual appeal, aesthetic versatility, and even functional benefits to steel coils in various applications.

- Q: What are the main challenges in handling and processing steel coils?

- The main challenges in handling and processing steel coils include their large size and weight, the risk of damage during transportation and storage, the need for specialized equipment and facilities, ensuring proper handling to prevent injury to workers, and addressing the potential for corrosion and rust. Additionally, the variability in coil dimensions and surface conditions can pose difficulties in achieving precise and consistent processing results.

- Q: i know theres steel in it but what else?

- Corrosion resistant steel. Iron carbon alloy with a minimum of 10.5% chromium (Cr) content.

- Q: I'm wondering if steel casings are bad for a 1911. I know that an AK-47 will eat up steel casings all day long, but steel casings are bad for, and can be hard on an AR-15. I only have brass for my AR and that will never change. I'm curious as to how a 1911 fairs with steel casings. Is it bad for the gun or does it not matter? I'm asking because steel cased rounds seem to be the only readily available ammo these days. Thanks

- This better placed in the hunting section of sports. That is the area for gun questions. I've never used that Russian stuff in my guns. I would stick with brass or Aluminum Blaser ammo.

Send your message to us

Galvalume Hot Dip Galvanized Steel Sheet in Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords