Hot-Dip Galvanized Steel Roof with Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Roof Description:

Hot-dip galvanized steel roof are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Roof:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

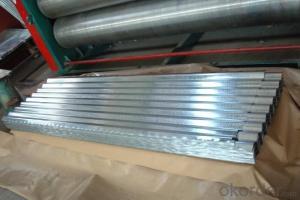

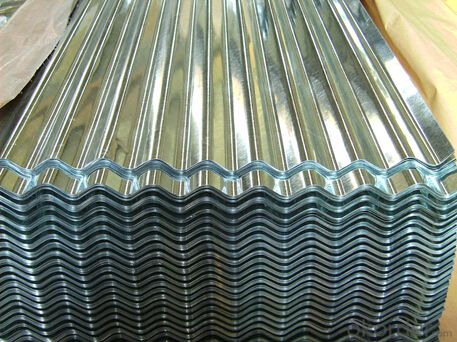

3.Hot-Dip Galvanized Steel Roof Images

4.Hot-Dip Galvanized Steel Roof Specification

Material: Galvanized Sheet

Width: 650/800/890/900

Length: 1500/1800/2000/2400/3005/3600 or customized

Thickness: 0.2-2.0

Surface Treatment: Hot dipped/Bended

Application: warehouse; shelter; Commercial facilities; industrial facilities

5.FAQ of Hot-Dip Galvanized Steel Roof

Which payment term we can do?

L/C at sight or T/T.

What’s the basic material of this product?

Galvanized/Aluzinc Steel

- Q: describe the benifits and disadvantages of the using steel as a material for fasteners

- There are different grades of steels which can suit different application considering corrosion,surrounding atmosphere,pressure,temperature and many more. Let us take the stainless steel fasteners: 1.Resists Rust: The primary advantage to using stainless steel bolts is that they resist rusting. This makes them ideal for outdoor or marine uses, since moisture will not cause them to corrode. Rust basically eats steel and makes it weaker. A rusty, weak bolt can be a serious safety risk, because it can break under a load. 2.Clean: Stainless steel bolts are very easy to clean due to having a higher content of chromium, which creates a lustrous, mirror-like surface that is very smooth. This makes stainless steel an ideal option if aesthetics are an issue. 3.Temperature: Stainless steel has a high melting point, which makes it a good option in machines that are put through immense amounts of heat. The bolts will not fuse together, and can be unfastened when the machines need repairs. Also, in very cold conditions, steel can become brittle. By mixing nickel into the stainless steel, the metal resists becoming brittle at low temperatures. See the source link for details.

- Q: Ok, lately I've been taking to making things out of stainless steel chain mallie rings. The problem is that when i make a bracelet or something, the area around the fastener always looks pretty bad. I'm thinking to have a friend who also does chain mallie finish the weave all the way around. This would make it look good but make it impossible to remove.Are there any long term problems with stainless steel on skin? I know some metals will change the color of the skin or make the skin absorb some of the metal. Is this something to worry about with stainless steel?

- Stainless steel contains both nickel and chromium. These two alloys are responsible for most of contact dermatitis in people. Some of my co-workers making steel had such bad reactions to chromium that they had to quit their jobs. Their skin was always inflamed. People don't react to finished stainless steel the same way because the alloys are bonded tightly in the heat treating process. But if you are grinding it and getting the dust on your skin, you could get a contact dermatitis if you are sensitive. I don't think it would absorb into your blood stream or do any long term damage to your skin. If you do get a reaction, you would have to cease your exposure or in a worse case scenario risk getting a body wide reaction like my coworkers. I would not worry about any exposure making rings out of stainless steel. After all, stainless steel is used in sugical implants and most people are fine.

- Q: How are steel coils used in the manufacturing of agricultural irrigation systems?

- Steel coils are used in the manufacturing of agricultural irrigation systems primarily for the fabrication of pipes and tubing. These coils are formed into the desired shape and size, allowing for efficient water transportation and distribution throughout the agricultural fields.

- Q: So, I'm doing this project for my chemistry class and I need to explain the raw materials in which paper slips are made of. I'm not really sure if galvanized steel is. If not, can someone PLEASE tell me what raw materials are metal paper clips made of???

- No, because first of all galvinizing is coating the steel with zinc to prevent oxidation. Iron is a raw material, as is zinc, carbon. Other metals may be combined with the iron and carbon, including vanadium and chromium.

- Q: How are steel coils annealed to improve their properties?

- Steel coils are annealed to improve their properties through a process called annealing, which involves heating the coils to a specific temperature and then slowly cooling them. This process helps to relieve internal stresses, enhance ductility and toughness, and refine the grain structure of the steel, resulting in improved mechanical properties such as increased strength and reduced brittleness.

- Q: Which type is better and give reasons why... I making a team of either Dark or Steel :D Thankyou

- Steel-type Pokemon are strong against Ice and Rock-type Pokemon, weak against Fire, Fighting, and Ground-type moves, resistant to Dark, Dragon, Ghost, Grass, Ice, Normal, Psychic, Rock, and Steel-type moves, and are immune to Poison-type moves. Notable Steel-type Pokemon include Skarmory, Scizor, and Metagross. Dark-type Pokemon are strong against Ghost and Psychic-type Pokemon, weak against Bug and Fighting-type moves, resistant to Ghost-type moves, and immune to Psychic-type moves. Notable Dark-type Pokemon include Houndoom, Murkrow, and Sneasel. Steel-type Pokemon have more resistances than Dark-types, but more weaknesses as well. In truth, no one type is better than any other, and making a team composed entirely of a single type may make some battles difficult. It's best to keep your options open, and go with a wide variety of types.

- Q: Where are the coils and the steel plates used? Where did the steel plate come from?

- Steel plate is divided into many kinds of PU, low alloy, boiler plate, vessel plate, high strength plate, etc..

- Q: What are the different methods of blanking steel coils?

- There are several methods for blanking steel coils, including shearing, laser cutting, and waterjet cutting. Shearing involves using sharp blades to cut the coil into desired shapes. Laser cutting utilizes a high-powered laser beam to accurately cut through the steel. Waterjet cutting involves the use of a high-pressure stream of water mixed with abrasive materials to cut the coil. These methods offer different levels of precision, speed, and cost-effectiveness depending on the specific requirements of the blanking process.

- Q: How are steel coils tested for strength?

- Steel coils are tested for strength using a variety of methods such as tensile testing, hardness testing, and impact testing. Tensile testing involves applying a controlled force to the coil until it breaks, measuring the amount of force required to rupture the steel. Hardness testing measures the resistance of the steel to indentation or scratching, providing an indication of its strength. Impact testing evaluates the ability of the steel to absorb energy under sudden loading conditions. These tests help determine the overall strength and quality of the steel coils.

- Q: I have some steel wool and a charged 9V Battery, when I connect 2 wires to the battery, then touch the wool with the ends of the wires the wool instantly starts burning, but when I connect 2 wires to the piece of steel wool (a new piece not same one of course) and touch the battery with the ends of the wire nothing happens (see image...)

- Steel Wool 9v Battery

Send your message to us

Hot-Dip Galvanized Steel Roof with Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords