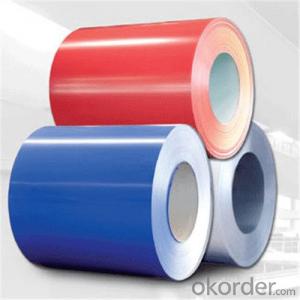

HOT DIP GALVANIZED STEEL IN COIL IN COIL

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HOT DIP GALVANIZED STEEL IN COIL

Thickness:0.13-2.0mm

Width:600-1500mm

Material:SGCC,DX51D,Q195

Coil weight:3-7 ton

Package:covered with waterproof-paper,strapped by strips. Standard seaworthy export package:4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection.

SPANGLE: normal spangle, large spangle, small(min) spangle, zero spangle

Application:construction field ,ships building industry ,Petroleum and chemical industries ,war and electricity industries ,food processing and medical industry,boiler heat exchanger, machinery and hardware fields

Auto Industry Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway

Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds

Industrial Instruments Electric control cabinet, industrial refrigeration equipment, automatic vending machine

- Q: How are steel coils used in the production of metal enclosures?

- Steel coils are widely used in the production of metal enclosures due to their versatility and strength. These coils, which are typically made from high-quality steel, serve as the primary raw material for manufacturing metal enclosures. Firstly, the steel coils are unrolled and flattened to the desired thickness using specialized machinery. This process ensures that the coils are in a suitable form for further processing. The flattened steel is then cut into specific sizes and shapes, depending on the design requirements for the metal enclosure. Next, the cut steel pieces are formed into the desired shape using various techniques such as bending, folding, and welding. These processes allow the steel to be molded into the required dimensions and structure of the metal enclosure. The inherent strength and durability of the steel coils ensure that the final product is sturdy and can withstand external forces or impacts. Additionally, steel coils can be coated with protective layers such as galvanization or powder coating to enhance their resistance to corrosion, rust, or other environmental factors. This coating helps to prolong the lifespan of the metal enclosure and maintain its aesthetic appeal. Moreover, the use of steel coils in the production of metal enclosures allows for customization and flexibility. The coils can be easily manipulated to create complex shapes or designs, enabling manufacturers to cater to specific customer requirements. This adaptability makes steel coils a preferred choice in industries such as automotive, electronics, and construction, where metal enclosures are widely used. In summary, steel coils play a crucial role in the production of metal enclosures by providing a strong and versatile raw material. These coils are transformed into the desired shape and size, ensuring the durability and functionality of the enclosures. With their customizable nature and protective coatings, steel coils offer a cost-effective solution for manufacturing high-quality metal enclosures.

- Q: How are steel coils used in the production of conveyor systems?

- Steel coils are used in the production of conveyor systems as they are formed into sturdy, durable belts that are capable of withstanding heavy loads and continuous operation. The coils are typically flattened and shaped into long lengths before being assembled into conveyor belts, ensuring optimal strength and flexibility for efficient material handling.

- Q: What are the different methods of annealing steel coils?

- There are several different methods of annealing steel coils, each with its own advantages and applications. The main methods include full annealing, process annealing, and spheroidize annealing. Full annealing is the most common method and involves heating the steel coils to a temperature above its critical point, typically between 800 and 900 degrees Celsius (1472 and 1652 degrees Fahrenheit), and then slowly cooling it down in a controlled manner. This process helps to refine the grain structure of the steel, making it softer and more ductile. Full annealing is often used to relieve internal stresses, improve machinability, and enhance the overall mechanical properties of the steel. Process annealing, also known as subcritical annealing or stress relief annealing, is a method used to reduce the hardness and brittleness of steel coils. It involves heating the coils to a temperature below its critical point, typically between 550 and 650 degrees Celsius (1022 and 1202 degrees Fahrenheit), and then slowly cooling them down. This process helps to relieve internal stresses that may have developed during previous manufacturing processes, such as cold working or welding. Process annealing is commonly used to improve the formability and toughness of steel coils. Spheroidize annealing is a specific type of annealing that is used to soften high carbon and alloy steels. It involves heating the steel coils to a temperature slightly below its critical point, typically between 650 and 700 degrees Celsius (1202 and 1292 degrees Fahrenheit), and then holding it at that temperature for a prolonged period of time. This allows the carbides within the steel to transform into rounded or spheroidal shapes, which increases the steel's machinability and ductility. Spheroidize annealing is often employed in the production of cutting tools, bearings, and other applications where improved machinability is desired. In addition to these main methods, there are also variations and specialized techniques that can be used for specific purposes, such as recrystallization annealing, intercritical annealing, and solution annealing. Each method has its own set of parameters and temperature ranges, and the choice of annealing method depends on factors such as the type of steel, desired mechanical properties, and the intended application of the steel coils.

- Q: What are the common coil grades available for steel coils?

- The common coil grades available for steel coils are typically classified into three main categories: low carbon steel, medium carbon steel, and high carbon steel.

- Q: I'm looking for the weight of different types of steel and haven't found anything helpful!!thank you

- Category Material Density Metal Steel, tool 7.715 Metal Wrought Iron 7.75 Metal Carbon Tool Steel 7.82 Metal Steel, cold-drawn 7.83 Metal Carbon Steel 7.84 Metal Steel, C1020, HR 7.85 Metal Pure Iron 7.86 Metal Soft Steel (0.06% C) 7.87 Metal Stainless Steel, 304 8.03 Metal Stainless 18Cr-8Ni 8.03 I looked up specific gravity mild steel. This might get you pointed in the right direction.

- Q: What are the dimensions of steel coils used in the electrical equipment industry?

- The dimensions of steel coils utilized in the electrical equipment industry may differ based on the particular application and requirements of the equipment being produced. However, there are certain dimensions that are commonly employed in this industry. Typically, the width of steel coils employed in the manufacturing of electrical equipment ranges from 0.5 inches to 72 inches (1.27 cm to 182.88 cm). The thickness of these coils can vary from extremely thin, measuring 0.005 inches (0.0127 cm), to considerably thick, measuring 0.25 inches (0.635 cm). The length of steel coils employed in the electrical equipment industry can also vary, but it is often determined by the production process and the specific equipment being manufactured. Coils can range in length from a few feet to several hundred feet. Moreover, the weight of steel coils can differ based on their dimensions and the type of steel being utilized. For example, a common weight range for steel coils employed in the electrical equipment industry falls between 5,000 pounds (2,268 kg) and 50,000 pounds (22,680 kg). It should be noted that these dimensions are not fixed and can vary depending on the specific requirements of the electrical equipment industry. Manufacturers may have their own distinct specifications and requirements for the steel coils they utilize in their products.

- Q: How are steel coils loaded and unloaded from ships?

- Steel coils are typically loaded and unloaded from ships using cranes or heavy machinery. The coils are lifted onto the ship using hooks or clamps, and secured in place to prevent movement during transportation. Once the ship reaches its destination, the coils are then carefully lifted off the ship and transferred to trucks or other modes of transportation for further distribution.

- Q: Are steel-capped boots safer than non-capped ones when working with horses? I have been told that sometimes if a horse steps on you, the steel crushing into your foot is more dangerous than if you just had normal wellies on, as at least with normal wellies there is some flexibility. Any horsey people out there got any experience with this? Thanks!

- In all my experience as a farrier steel toes have neither helped nor caused any problem. I would be a vary rare case that the horse would be able to collapse the steel and with that much force the steel bending would be the last of your problems because your foot would have been completely destroyed without it. I agree with being alert a nd trying to get your feet out of the way. The few times i've been hurt the horse has chopped down toe first on the arch of my foot high above where there steel is any way. I've oddly enough never had a problem with getting my toes stepped on it really doen't seem to hurt if they land flat footed.

- Q: How are steel coils protected from humidity?

- Steel coils are typically protected from humidity through a process called galvanization, where a layer of zinc is applied to the surface of the steel. This zinc coating acts as a barrier, preventing moisture from coming into contact with the steel and causing corrosion. Additionally, the coils may be stored in a controlled environment with low humidity levels to further protect them.

- Q: How do steel coils contribute to the construction equipment industry?

- The construction equipment industry relies heavily on steel coils as they are vital for manufacturing various construction machinery and equipment. These coils, made from high-quality steel, are crucial components used in the fabrication of a wide range of construction equipment, including cranes, bulldozers, excavators, loaders, and forklifts. The main contribution of steel coils to the construction equipment industry lies in their structural strength and durability. Steel is renowned for its exceptional mechanical properties, such as high tensile strength, toughness, and resistance to wear and corrosion. These properties make it an ideal material for constructing heavy-duty machinery capable of withstanding the demanding conditions of construction sites. Steel coils are employed in the production of the structural components of construction equipment, such as chassis, frames, booms, buckets, and attachments. These components need to be sturdy and able to endure heavy loads, impacts, and continuous use. Steel coils provide the necessary strength and reliability to ensure the long-lasting performance of construction equipment. Moreover, steel coils are also used to manufacture specialized parts and accessories for construction machinery. These include hydraulic systems, gears, shafts, bearings, and fasteners. These components are essential for the proper functioning and efficiency of construction equipment, and steel coils provide the high-quality material required for their production. In addition to their mechanical properties, steel coils also contribute to the construction equipment industry through their versatility and customization options. Steel can be easily shaped, cut, welded, and formed into various sizes and shapes, allowing manufacturers to create equipment with specific designs and functionalities tailored to meet the diverse needs of construction projects. Overall, steel coils are indispensable in the construction equipment industry as they serve as the foundation for robust and reliable machinery. Their strength, durability, and versatility make them an essential raw material for manufacturing construction equipment that can withstand the challenges of construction sites and ensure the safety and efficiency of construction projects.

Send your message to us

HOT DIP GALVANIZED STEEL IN COIL IN COIL

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords