Hot-Dip Galvanized Steel Coil-- Good Formability

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

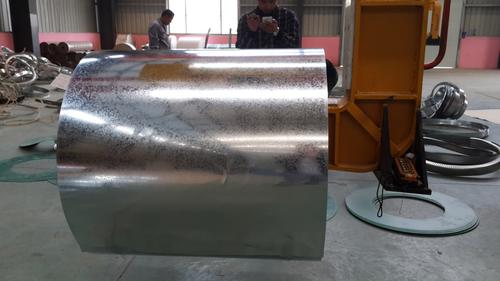

Hot-Dip Galvanized Steel Coil-- Good Formability

Brief Introduction

Hot-Dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanized process. It offers the economy, strength and formability ofsteel combined with the corrosion resistance of zinc. The hot-dip process isthe process by which steel gets coated in layers of zinc to protect againstrust. It is especially useful for countless outdoor and industrial applications, such as roofing, cladding, decking, tiles, sandwich walls, airconditioning duct as well as electrical appliances and engineering.

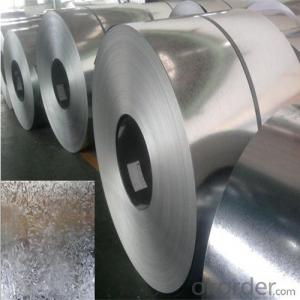

MainSpecification

HOT DIP GALVANIZED STEEL | |

THICKNESS | 0.13-0.8MM |

WIDTH | 900-1250MM |

ZINC COATING | 60-275g/m2 |

COIL ID | 508MM OR 610MM |

SURFACE TREATMENT | CHROMATED/UNCHROMATED, OILED/DRY |

COIL WEIGHT | 1-12MT |

The image

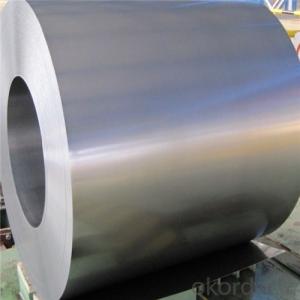

Application

Galvanizedsteel coil/sheet products are mainly used in construction, light industry,automobile, farming and commercial fishing industries.

Whichconstruction industry, mainly used in the manufacture of industrial and civilcorrosion roof, roof grille.

Lightindustry with its manufacture appliance housing, civil chimney, kitchenutensils, automotive industry, mainly for the manufacture of car parts andother corrosion-resistant; husbandry and fishery owners do use food storage,frozen meat and aquatic products processing equipment, etc. Business mainlyused as storage and transportation of materials, packaging equipment, etc.

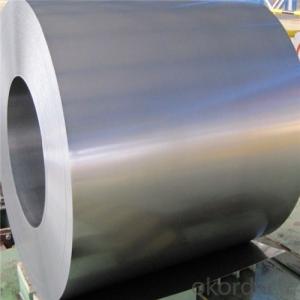

Package &Delivery

Packagedetails: Standard seaworthy packing for international delivery.

Delivery:According to the exact quantity of your order.

5. FAQ

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the common methods of cutting-to-length steel coils?

- The common methods of cutting-to-length steel coils include shearing, slitting, and sawing.

- Q: Don't ask me why, but I took my stainless steel ring and I heated it up with my gas stove. I stuck it in there til the metal turned red, and the flame which is normally blue turned orange for some reason when the metal turned red. Anyway, afterwards i cooled it off in water and now it's all discolored and it feels different. It's weighs less and it doesn't feel the same. Plus, it's ugly cause it's all black and blue. What happened? Someone help

- I would first check it with a magnet. If it is attracted to the magnet it has too much steel in it and that is what oxidized,not the CR. U might try to clean it with a good acid .

- Q: How are steel coils unloaded from a truck?

- Steel coils are typically unloaded from a truck using a combination of heavy-duty forklifts, cranes, and specialized equipment. The coils are carefully lifted and positioned onto the ground or a designated storage area, ensuring proper safety measures and precautions are followed to prevent any damage or accidents during the unloading process.

- Q: I'm buying a new set of steel plugs.I've heard things about streched ears and cold weather not being to good. do you think it would be bad to be wearing steal plugs?

- Personally, okorder They are spot on for sizing, they do customs, and amazing quality like i have never seen before and I have been through a lot of plugs. Hope this helps :)

- Q: Why is steel used for building purpose and not any other metal?

- Steel is used over most other metals due to its desireable properties for buildings. To name a few: strength, hardness, ductility, conductivity, flexability, weight, ability to shape/mold, non-combustability, weather resistance and cost Many other metals have the same properties, only on different scales. For instance, copper may be an excellent conductor, howwever it's expensive and not very weather resistant. Aluminum may be flexible, moldable, but not very strong. The list goes on and on..

- Q: How are steel coils inspected for defects after rewinding?

- Steel coils are inspected for defects after rewinding by using various techniques such as visual inspection, ultrasonic testing, magnetic particle inspection, and eddy current testing. These methods help identify surface irregularities, cracks, or other defects that may have occurred during the rewinding process, ensuring the quality and integrity of the steel coils.

- Q: I'm just wondering what the best steel would be for an edc/hunting knife that could put up with alot of abuse.

- D2 and O2 steels are nice. They are expensive, but hold an edge extremely well. S30V is nice also. It's a more stain-resistant steel that holds an edge very well. For outdoor hiking/camping knives, it's tough to beat good old 1095 carbon steel. Sure it will rust, but it's tough as nails, not brittle, holds an edge pretty well, and easy to sharpen...and it's pretty cheap. Other steels, AUS8 is an ok cheap steel. It's stain resistant and cheap. AUS6 isn't worth the time or effort. Buck knives does an excellent job of heat treating 420 stainless to become very hard. Their knives are excellent considering 420 stainless is typically soft steel.

- Q: What are the dimensions of steel coils used in the oil and gas industry?

- The dimensions of steel coils used in the oil and gas industry can vary depending on the specific application and requirements. However, there are some common dimensions that are frequently used. Steel coils used in the oil and gas industry typically have a width ranging from 600mm to 2000mm. The outer diameter of the coil can range from 800mm to 2200mm, while the inner diameter can range from 508mm to 610mm. The weight of the coil can vary as well, ranging from a few tons to several tens of tons. These dimensions are designed to meet the needs of various processes involved in the oil and gas industry, such as pipe manufacturing, storage tank fabrication, and offshore platform construction. It is important to note that these dimensions are not fixed and can be customized based on the specific requirements of each project.

- Q: I juuuust got a new stainless steel sink only 5 months ago, and it already has a couple rust spots on it.What caused this?!

- if you leave any cast iron pans sit in the sink, rust will show or any silverware also, you can get rid of them with scouring powder but dont scrub too hard or you will scratch the sink

- Q: Are they made using the same processes, or is tempered steel made without the quenching process?

- Hardening is the preliminary process. The fully hardened state may be far too brittle for practical use. The tempering process is tailored to reduce the actual hardness, to introduce more flexible alloys. The tempering method employed may be done at relatively low temperatures, but some alloys require prolonged soaking at elevated temperatures. Some may be cooled in air, but others may require quenching to end the process.

Send your message to us

Hot-Dip Galvanized Steel Coil-- Good Formability

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords