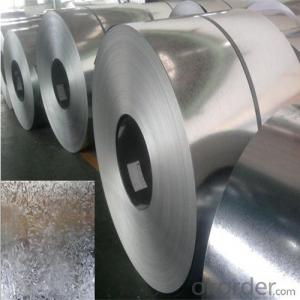

NO.1 BEST HOT-DIP GALVANIZED STEEL COIL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details |

|

|

|

|

|

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC,DX51D/DX52D/S250,280GD | Thickness: | 0.12-4.0 mm |

Place of Origin: | Brand Name: | N/M | Model Number: | ssp-226 | |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | galvanized/ Galvalume/zinc coatting |

Application: | strong anti-corrosion ability,cold bending molded manufacturablity | Special Use: | High-strength Steel Plate | Width: | 600-1250 mm |

Length: | in coil | product: | g40 prime/secordary hot-dip galvanized cold rolled steel coil/sheet |

|

|

Packaging & Delivery |

|

|

|

|

|

Packaging Detail: | standard export package,Other types of packing can be customized as per client's requirement. | ||||

Delivery Detail: | as per client's requirements | ||||

Specifications

1.Mateials:SGCC,DX51D / DX52D /S250,280GD

2.Size:width:600-1250mm(900mm,1215mm,1250mm,1000mm the most common)

thickness:0.15-2.0mm

length:1000-6000mm,as your require

3.Zinc coating :60-180g( as required)

4.Coil id:508mm

5.Coil weight: 3-5MT(as required)

6. Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

7. Application:

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils.

8.PackagingDetails:

Standardexport package.

Othertypes of packing can be customized as per client's requirements.

- Q: Which is more reactive? Zinc or Steel? And why?

- Zinc. Steel is an alloy consisting mostly out of iron, In the reactivity seris, zinc is more reactive than iron. Therefore, zinc is more reactive than steel

- Q: How are steel coils used in the manufacturing of agricultural structures?

- Due to their durability, strength, and versatility, steel coils play a vital role in the manufacturing of agricultural structures. Typically made from high-quality steel, these coils are utilized in various ways throughout the construction process of agricultural buildings such as barns, silos, and storage facilities. One primary application of steel coils in agricultural structures is seen in the creation of the building's framework. The coils are unwound, cut into specific lengths, and then bent, shaped, and welded together to form the structural framework. The exceptional strength and rigidity of steel coils make them an ideal choice for withstanding the heavy loads and harsh environmental conditions commonly found in agricultural settings. Moreover, steel coils are also used in the production of different components and accessories for agricultural structures. These coils can be transformed into panels, roofing sheets, doors, and windows, which are essential elements in constructing agricultural buildings. The ability to customize the shape, size, and thickness of the steel coils allows for flexibility in design and ensures that the finished structure meets the specific requirements of the agricultural application. Furthermore, steel coils play a crucial role in providing protection and safety within agricultural structures. They are employed in fabricating fencing and gates, creating secure boundaries and preventing unauthorized access. Steel coils can also reinforce the walls and floors of the building, enhancing its stability and durability. Additionally, steel coils offer excellent resistance to corrosion, which is particularly important in agricultural structures due to exposure to moisture, chemicals, and other corrosive elements. Their durability ensures that the structure remains intact and functional for an extended period, thereby reducing maintenance and replacement costs. In conclusion, steel coils are indispensable in the manufacturing of agricultural structures. Their strength, durability, versatility, and resistance to corrosion make them an ideal choice for constructing the framework, components, and accessories of these buildings. By utilizing steel coils in the manufacturing process, agricultural structures can be built to withstand heavy loads, harsh environmental conditions, and provide long-lasting protection for agricultural operations.

- Q: How do steel coils contribute to the manufacturing of agricultural machinery?

- The manufacturing of agricultural machinery heavily relies on steel coils, which play a vital role in this process. Typically, these coils are crafted from top-notch steel that possesses exceptional strength, durability, and resistance to corrosion. To begin with, agricultural machinery heavily relies on steel coils for the construction of its main structural components, including the chassis, frames, and supports. These components must endure heavy loads, extreme weather conditions, and rough terrains. Thanks to the strength and resilience of steel coils, the machinery can effectively handle these challenging environments and operate efficiently. In addition, steel coils find application in the production of various moving parts and mechanisms within agricultural machinery. For example, gears, shafts, and axles, which are crucial for power transmission and rotational motion transformation, are created using steel coils. The high tensile strength and excellent machinability of steel make it an ideal material for these essential components, ensuring their reliability and longevity. Moreover, steel coils contribute to the manufacturing of agricultural machinery by providing a protective layer against wear and tear. Often, these coils are coated with specialized finishes or paints to enhance their resistance to rust, chemicals, and abrasion. This protective layer significantly prolongs the machinery's lifespan, reduces the need for frequent maintenance and repairs, and ultimately increases its overall efficiency and productivity. Furthermore, the versatility of steel coils allows for customization and adaptation to meet the specific requirements of agricultural machinery. Manufacturers can shape and mold the coils into different sizes and dimensions, enabling the production of machinery suitable for various farming practices and applications. Whether it's tractors, harvesters, or irrigation systems, steel coils are crucial for creating versatile and dependable agricultural machinery. In conclusion, steel coils are essential in the manufacturing of agricultural machinery due to their strength, durability, resistance to corrosion, and customization capabilities. From structural components to moving parts and protective coatings, steel coils greatly contribute to the efficiency, reliability, and longevity of agricultural machinery, thus providing significant support to the global agricultural industry.

- Q: How are steel coils used in the manufacturing of household goods?

- Steel coils are commonly used in the manufacturing of household goods as they are shaped and processed into various components such as frames, springs, and supports. These coils provide strength, durability, and stability to items like furniture, appliances, and automotive parts, ensuring their longevity and functionality.

- Q: How are steel coils inspected for surface defects after processing?

- Steel coils are inspected for surface defects after processing through a visual inspection process. Specially trained inspectors carefully examine the coils for any visible defects such as scratches, dents, or irregularities in the surface. They use advanced lighting techniques and magnification tools to ensure a thorough inspection. Additionally, automated systems may also be employed to detect and flag any defects that may have been missed during the visual inspection.

- Q: How are steel coils used in the production of automotive structures?

- Steel coils are used in the production of automotive structures in various ways. Firstly, steel coils are used as the primary material for manufacturing car bodies and frames. These coils are typically made of high-strength steel, which is known for its durability and crashworthiness. The steel coils are processed and formed into different automotive components, such as panels, doors, roofs, and pillars. Additionally, steel coils are also used to make various structural components in an automobile. For example, they are used to create suspension systems, chassis, and other critical parts that provide stability, strength, and support to the vehicle. Steel coils are often used in the production of structural beams, reinforcement bars, and other load-bearing components that ensure the vehicle's overall strength and safety. Moreover, steel coils are used for manufacturing automotive parts that require precise shaping and forming processes. These coils are fed into stamping presses, where they undergo a series of operations like cutting, bending, and shaping to create intricate parts like brackets, brackets, brackets, and brackets. The versatility of steel allows for the production of complex automotive structures with high precision and accuracy. Additionally, steel coils are also used in the production of automotive exhaust systems. These coils are typically made of stainless steel, which offers excellent resistance to corrosion and high temperatures. They are formed and welded into exhaust pipes, mufflers, and catalytic converters, ensuring the durability and longevity of these crucial components. In summary, steel coils play a crucial role in the production of automotive structures. They are used to create car bodies, frames, suspension systems, chassis, and other structural components. Steel coils are also vital for manufacturing precise and complex automotive parts, as well as exhaust systems. Overall, steel coils contribute to the strength, safety, and longevity of automotive structures.

- Q: How are steel coils processed into finished products?

- Steel coils are processed into finished products through a series of steps including uncoiling, leveling, cutting, shaping, and surface treatment. The uncoiling process involves unwinding the steel coil to create a flat sheet. Next, leveling machines remove any unevenness in the sheet's surface. Then, the sheet is cut into desired lengths or shapes using cutting machines. Shaping processes such as bending, rolling, or stamping are performed to achieve the desired product form. Finally, surface treatment techniques like galvanizing, painting, or coating are applied to enhance the product's durability and appearance.

- Q: Which one would be stronger? And should damascus steel be tempered?Thank You

- carbon steel it is stronger it is the type ill be using when i stare forging

- Q: What are the common coil packaging methods?

- The common coil packaging methods include shrink wrapping, strapping, banding, and stretch wrapping.

- Q: for my engineering project I have been asked to design a method of suspending a TV of weight 14Kg from a gantry, the TV must be 5m below the gantry. My team have decided to use as a suspension method a steel cylinder of outer diameter of 10cm and an inner diameter of 8, however we now need to work out both the max stress and strain and the actual stress and strain. and help would be useful

- In most engineering calculations we have to make some assumptions about ideal behavior of a material otherwise we would not be able to simplify our equations to manageable sizes. Your steel cylinder (which I'll call a pipe) is made of a certain type of steel. That steel type has property tolerances listed in a steel manual to help you know about your steel before you begin. You'll need to know the cross-sectional area of the pipe and the weight of the TV to determine an average stress on the pipe. Obviously the weight of the TV is the force it generates. The force is its mass x gravitational acceleration. Since we typically think of steel as an elastic material, we think of it stretching like a rubber band or a spring. You pull it down with a TV and it deflects a certain amount, and will return to its original length when the TV is removed. It is typical to assume that all steel, regardless of its strength, has the same value for this elastic property. It is commonly referred to as the elastic modulus. This value will help you determine what type of strain occurs under what type of stress. So, once you have the stress, you can get the strain by using the elastic modulus. Once you have the strain you can determine the deflection based on the pipe length. Having the steel properties will help you determine how close your TV comes to stressing the pipe to its yield stress. If you reach a yield stress, your steel will deflect, but when you take the TV off it will not return to its original shape. I hope I've helped outline some of the things you'll need to do for the project, I tried not to give away specifics so that you can actually engage your brain around the project. Enjoy, learn a lot, and realize that this skill could easily turn into a career where you are designing projects that when done correctly save people's lives every day of the year.

Send your message to us

NO.1 BEST HOT-DIP GALVANIZED STEEL COIL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords