Pre-Painted Galvanized/Aluzinc Steel Coil with Best Price in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil with Best Quality in China

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

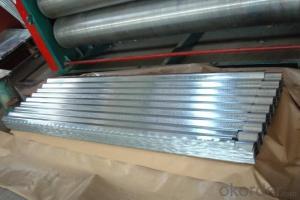

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: im buying a new guitar,, it has a built in tuner and its semi acoustic (can be plugged into an amplifier) ,, im trying to choose which strings are better ,, steel or nylon..?

- Musical style speaks volumes when it comes to this issue. Those who want high volume will be unhappy with unamplified nylon string guitars. From my perspective, the basic difference between steel and nylon is this: steel strings ring and nylon strings resonate. The volume produced by steel is generally much greater than nylon but, to my way of thinking, the sound resonance produced by the wood of your guitar is largely masked by steel strings. If you have a decently made guitar (generally, around a thousand dollars and up), the sound interplay between the wood and the strings in a nylon guitar is magical across the entire frequency range. With a steel string guitar, the sound produced by the vibrating string overpowers the wood resonance at all but low frequencies. Personally, I'll take a nylon string guitar any day for the sensitivity gained from the interplay between wood and vibrating string.

- Q: i'm looking into buying a stainless steel ring for somebody as a gift.i'm on a budget (heh) and the ring is about $50.will it rust or tarnish? it'd be embarrassing if i gave it to someone, and it begins rusting :Pthanks

- Stainless steel is a generic term for a huge variety of different alloys. In manufacturing, each steel has different numbers, etc that they go by. Some steel sold as being stainless actually is not. It rusts, like the cheap kitchen knives you see that are left in the sink too long. However, the stainless in jewelry is pretty legit. Overpriced, but legit. It will not tarnish, but it won't stay shiny forever. It might get a little less glossy over time. When it does get re-polished, it takes a long time to do it. But it will not turn black or rust. Good luck.

- Q: What are the safety precautions while handling steel coils?

- When handling steel coils, it is important to follow certain safety precautions to prevent accidents and injuries. Here are some key safety measures to consider: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE such as steel-toed boots, safety glasses, gloves, and a hard hat. PPE will protect you from potential hazards, including falling objects, sharp edges, and flying debris. 2. Training and Proper Lifting Techniques: Ensure that workers involved in the handling of steel coils have received proper training on safe lifting techniques. This includes using the legs to lift, keeping the back straight, and avoiding twisting motions. Proper lifting techniques reduce the risk of back strains and injuries. 3. Secure Storage and Stacking: When storing or stacking steel coils, make sure they are placed on a level and stable surface. Use appropriate storage equipment such as racks or pallets to prevent coils from shifting or falling. Securely stack the coils to avoid toppling or collapsing. 4. Inspection and Maintenance: Regularly inspect steel coils for any defects, such as sharp edges, loose bands, or damaged packaging. Avoid handling coils that appear damaged or unstable. Maintenance of equipment, such as forklifts or cranes, used for moving the coils should be regularly conducted to ensure safe operation. 5. Communication and Signaling: Implement clear communication and signaling protocols between workers involved in handling steel coils. This can include hand signals or radio communication to coordinate movements and prevent accidents, especially in areas with restricted visibility. 6. Load Limits and Capacity: Be aware of the load limits and capacity of the equipment being used to move steel coils, such as forklifts or cranes. Overloading equipment can lead to instability, tipping, or collapse, increasing the risk of accidents and injuries. 7. Proper Lashing and Securing: When transporting steel coils, use appropriate lashing and securing methods to prevent movement or falling during transportation. This may include using straps, chains, or other restraints to keep the coils in place. 8. Emergency Preparedness: Have an emergency plan in place in case of accidents or injuries. Ensure that workers are trained in first aid and that emergency response equipment, such as fire extinguishers and first aid kits, are readily available. By following these safety precautions, the risk of accidents and injuries while handling steel coils can be significantly reduced, creating a safer work environment for all involved.

- Q: How are steel coils used in the production of conveyor systems?

- Steel coils are used in the production of conveyor systems as they are transformed into various components such as conveyor belts, rollers, and frames. These components provide the necessary strength, durability, and support required for efficient material handling and transportation in conveyor systems.

- Q: What is the process of slitting steel coils into narrower strips?

- The process of slitting steel coils into narrower strips involves unwinding the steel coil, passing it through a set of rotating circular blades called slitters, and then rewinding the resulting narrower strips onto separate spools.

- Q: What are the dimensions of steel coils used in the agricultural equipment industry?

- The dimensions of steel coils used in the agricultural equipment industry vary depending on the specific application and requirements of the equipment. However, some common dimensions for steel coils used in this industry range from 0.5mm to 6mm in thickness and 600mm to 2000mm in width. The length of the coils can be customized based on the needs of the specific equipment. Additionally, the weight of the coils can also vary, typically ranging from a few hundred kilograms to several tons. It is important to note that these dimensions are not fixed and may vary depending on the manufacturer and the specific agricultural equipment being produced.

- Q: Are steel coils used in the packaging industry?

- Yes, steel coils are commonly used in the packaging industry for various purposes such as securing and stabilizing loads, protecting products during transportation, and providing structural support to packaging materials.

- Q: How are steel coils used in the production of electrical systems?

- Steel coils are used in the production of electrical systems as they serve as the core component of transformers and inductors. They provide a magnetic field necessary for the efficient functioning and transformation of electrical energy.

- Q: The knife will be large and thick. Like the Bowie knife Rambo uses in Rambo III. It doesn't need to be flexible or to hold the edge very well. But i need it to be exceptionally strong material and to stop corrosion at least decently. Is Damascus Steel good?Thank you, in advance.

- If it does not could desire to hold an part o.k. then 440 stainless could be your appropriate guess. I want severe carbon steel. yet they require alot of cleansing and oiling or they're going to rust.

- Q: How are steel coils used in the manufacturing of automotive fuel tanks?

- Steel coils are used in the manufacturing of automotive fuel tanks as they are shaped and welded to form the structure of the tank. The coils provide strength and durability to the tank, ensuring it can withstand the pressure and impact of the fuel. Additionally, the steel coils are often coated to prevent corrosion and ensure longevity of the fuel tank.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil with Best Price in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords