color coated galvanized steel rolled coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Size | Thickness | 0.18-2 mm ,all available . |

Width | 40—1250mm, Steel Strips; 600—1250mm,Steel Sheets. | |

Length | Coil:Ususl weight of coil is 3-8tons Sheet:600-11000mm ,all are available. | |

Standard | AISI,ASTM,GB,JIS,Etc | |

Material | DX51D/52D/53D ;DC01/02/03 | |

MOQ | 20 Tons For Each Size And Each Color | |

Paint Specification | 1. Thickness: ≥20μm 2. Pencil Hardness: 2H 3. 60° specular glossiness of coating: >60 4. 180°bend: ≤3T 5. Impact: ≥9J 6. Salt Fog Resistant: ≥500h 7. Color difference:<0.8δe< span=""> | |

Coil Info | Coil ID | 508/610 mm |

Coil Weight | 3-8 Tons For Each Coil/Sheet | |

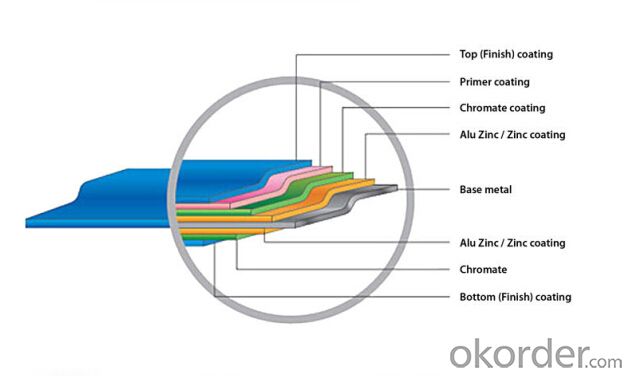

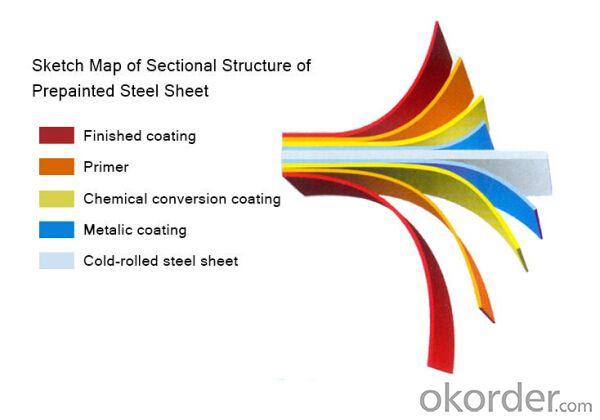

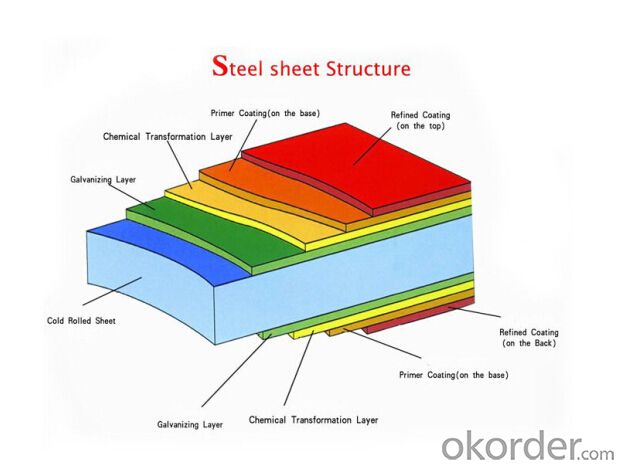

Coating (Zinc&Color)

1.Zinc Coating: As usual ,the zinc coating is 50-60g/m2 ,The range will be 40-275g/m2 .

2.Color: Done as the international RAL color chart ,and can also done as customers' color sample .

3.Painting: Front Painting:15-25 μm

Back Painting:5-10 μm

Features of Prepainted Steel Coil :

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

- Q: What is the maximum temperature that steel coils can withstand?

- The maximum temperature that steel coils can withstand depends on the specific grade and type of steel being used. However, in general, steel coils can withstand temperatures up to around 1,300 to 1,500 degrees Celsius (2,372 to 2,732 degrees Fahrenheit) before they start to lose their structural integrity and develop deformation or other forms of damage.

- Q: I'm a big fan of stainless steel and sterling silver, but not of the humidity of the country I'm in. Therefore I sweat more. Gross, I know. I'm buying a necklace chain for my ring.So does sweat contribute to tarnishing of silver and steel? The real kind?

- steel shouldn't really tarnish, it rusts and moisture increases that. Silver tarnishes when exposed to air and sulfur. Moisture increases the process a bit, but it happens anyway. Sweat is not gross, it's a necessary function of your body, otherwise you would die. A lot of sports people wear jewelry and they sweat a lot. If you wear the jewelry all the time, that will prevent the tarnish a bit. If you take it off, clean it (water and dish washing liquid), dry it and put it in a zip lock back to keep it away from air and moisture. In the end, cleaning the jewelry is quick and easy so don't worry about it.

- Q: How do steel coils compare to other materials, such as aluminum or copper?

- Steel coils have several advantages over other materials such as aluminum or copper. Firstly, steel is generally stronger and more durable, making steel coils less prone to damage or deformation. Additionally, steel has better heat resistance and can withstand higher temperatures, making it suitable for a wider range of applications. Steel coils also tend to be more cost-effective compared to aluminum or copper, making them a popular choice in various industries.

- Q: How do steel coils contribute to structural integrity in buildings?

- Steel coils play a crucial role in contributing to the structural integrity of buildings in several ways. Firstly, steel coils are widely used in the construction industry for manufacturing various building components such as beams, columns, and trusses. These components are responsible for providing support and stability to the overall structure. Due to their high tensile strength and durability, steel coils ensure that these components can withstand heavy loads and maintain their structural integrity over time. This is especially important in buildings with multiple floors or large open spaces, where the structural elements need to bear significant weight without deforming or collapsing. Secondly, steel coils are also used in the reinforcement of concrete structures. Reinforced concrete is a widely adopted construction method, and steel coils, in the form of reinforcement bars or mesh, are embedded within the concrete to counteract tensile forces. Concrete is excellent at withstanding compressive forces but weak in tension. By adding steel coils, the composite material gains the ability to resist both compression and tension, leading to enhanced structural integrity. This reinforcement technique is particularly vital in high-rise buildings or structures subject to seismic activity, where the risk of structural failure due to bending or cracking is higher. Another way steel coils contribute to structural integrity is through their corrosion resistance properties. Steel coils are often coated with protective layers, such as zinc through galvanization or paint, to prevent corrosion caused by moisture, chemicals, or environmental factors. Corrosion weakens the structural integrity of steel, leading to degradation and potential failure. By using corrosion-resistant steel coils, the lifespan of the building is extended, and the risk of structural damage is significantly reduced. Furthermore, steel coils offer versatility in design and construction. Their flexibility and malleability allow for the creation of complex and intricate building structures, enabling architects and engineers to push the boundaries of design while maintaining structural integrity. Steel coils can be shaped, bent, and welded into various forms, making them an ideal material for constructing innovative and aesthetically pleasing buildings. In conclusion, steel coils contribute significantly to the structural integrity of buildings by providing strength, stability, and durability to various components and reinforcement systems. Their high tensile strength, corrosion resistance, and versatility in design make them an indispensable material in modern construction, ensuring the safety and durability of buildings for years to come.

- Q: I got a muzzy carp point arrow and its head is steel with 1.7% carbon, its used in the water. Will i have to dry it after every use or is it stainless. Thanks

- Does it say stainless steel on it?

- Q: How do steel coils contribute to strength and stability in structures?

- Steel coils contribute to strength and stability in structures due to their inherent properties. The coils are made of high-strength steel, which provides excellent tensile strength and resistance to deformation. When used in structural components such as beams, columns, or foundation systems, steel coils reinforce the structure and help distribute loads evenly, enhancing its overall strength and stability. The flexibility and durability of steel coils also enable structures to withstand external forces, such as wind or seismic loads, without significant deformation or failure.

- Q: How are steel coils used in the production of electrical devices?

- Steel coils are an essential component in the production of electrical devices. These coils are typically made from high-quality steel that is precisely wound into a circular shape. They play a crucial role in the functioning of various electrical devices, such as transformers, motors, generators, and inductors. One primary use of steel coils is in transformers. Transformers are vital for stepping up or stepping down voltage levels in electrical circuits. They consist of two separate coils, known as the primary and secondary coils, which are wound around a magnetic core. The steel coil provides stability and support to the windings, ensuring proper alignment and preventing any deformation. Additionally, the high magnetic permeability of steel helps to enhance the efficiency of energy transfer between the coils. In motors and generators, steel coils are employed to create magnetic fields that generate mechanical energy or convert it into electrical energy. The coils are wound around an armature or rotor, which rotates within a magnetic field created by a stator. As the current flows through the coils, a magnetic field is produced, resulting in the rotation of the armature or the generation of electrical power. Inductors, another type of electrical device, also utilize steel coils. An inductor is essentially a coil of wire wound around a core material, often made of steel. Steel coils in inductors help to increase the inductance, which is a measure of the device's ability to store energy in a magnetic field. By storing energy in this manner, inductors can regulate currents, filter out noise, and provide stability to electrical circuits. Overall, steel coils play a vital role in the production of electrical devices by providing stability, support, and enhancing the magnetic properties necessary for their efficient functioning. Without steel coils, the performance and reliability of electrical devices, such as transformers, motors, generators, and inductors, would be significantly compromised.

- Q: How are steel coils used in the production of transportation systems?

- Steel coils are used in the production of transportation systems for various applications such as the manufacturing of automobile parts, railway tracks, and shipping containers. The coils are typically used to create strong and durable components that can withstand the harsh conditions and heavy loads associated with transportation.

- Q: Can steel coils be cut?

- Yes, steel coils can be cut.

- Q: How do steel coils differ in terms of size and weight?

- Steel coils can vary greatly in terms of size and weight depending on their intended use and production process. The size of a steel coil is typically measured in terms of its outer diameter, inner diameter, and width. The outer diameter refers to the total diameter of the coil, while the inner diameter refers to the diameter of the hollow center of the coil. The width of the coil refers to the distance between the two flat sides of the coil. In terms of weight, steel coils can range from a few hundred pounds to several tons. The weight of a coil is primarily determined by its size and the type of steel used. Coils made from high-strength steel tend to be heavier due to their higher density, while coils made from lower-grade steel can be lighter. The size and weight of steel coils are crucial factors in determining their transportability and handling. Smaller and lighter coils are generally easier to handle and transport, making them more suitable for applications where maneuverability is important. On the other hand, larger and heavier coils are often used in industries where strength and durability are essential, such as construction and automotive manufacturing. Overall, steel coils can vary significantly in terms of size and weight, allowing for a wide range of applications and customization to meet specific requirements in various industries.

Send your message to us

color coated galvanized steel rolled coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords